Ductile iron castings play a crucial role in the mechanical manufacturing field due to their high strength and good toughness. However, casting defects are like "roadblocks" on the quality journey, causing many casting managers a great deal of trouble.

However, you might not expect that the root causes of the seven common types of defects in ductile iron casting production are all closely related to the selection and use of spheroidizing agents. Understanding the intrinsic connection between spheroidizing agents and defects is the key to improving casting quality and reducing scrap rates.

2025-07-30 13:24:19

440C alloy, also known as stainless steel alloy 440C, is a high-carbon martensitic stainless steel that offers excellent hardness and wear resistance. This alloy is also known by other names such as X105CrMo17 or 1.4125 and is widely used in the automotive industry due to its outstanding performance. We will explore the various applications and advantages of 440C alloy in the automotive field.

2025-07-24 15:07:09

42CrMo4 (equivalent to the national standard 42CrMo) is a commonly used medium carbon alloy structural steel, featuring high strength, good toughness and hardenability. It is widely used in manufacturing important components such as shafts, gears and connecting rods. Its typical heat treatment process is as follows:

2025-07-24 15:05:38

So the question arises: since there are already indicators for judging the plasticity of materials, why go to the trouble of creating a "reduction of area"? It's like, if Zhu Di had already intended in his heart to let Zhu Gaoxu inherit the throne, why did he appoint Zhu Gaochi as the crown prince? Was he just bored or was there some hidden reason?

2025-07-23 16:02:58

In the field of mechanical engineering, metal fatigue is like a "chronic disease" in the material world - parts gradually develop cracks under repeated stress and eventually break suddenly. This kind of failure often occurs when the material seems intact, so improving fatigue strength is crucial for ensuring engineering safety.

2025-07-23 15:55:21

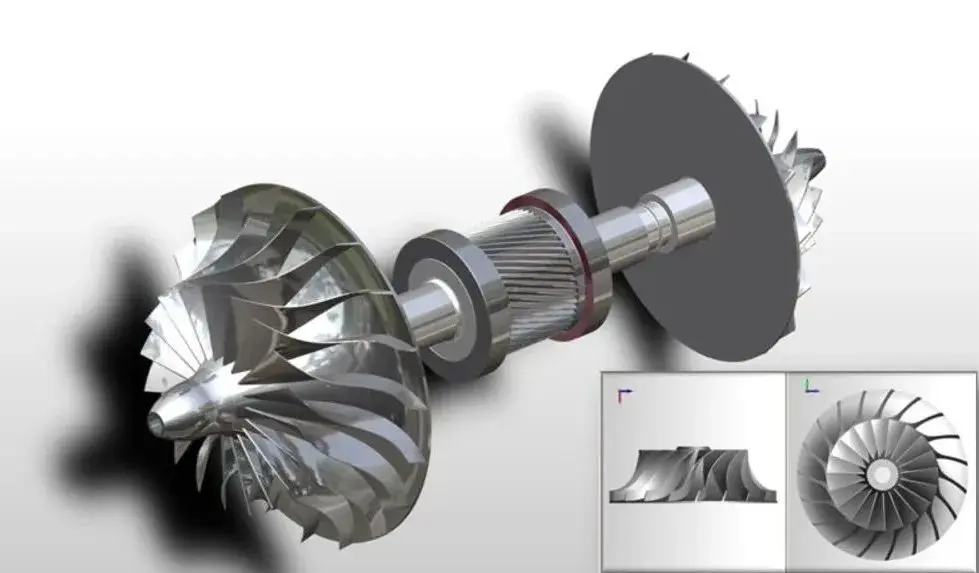

The impeller of a centrifugal compressor plays a core role in its structure, and the material selection of the impeller directly affects the performance, lifespan and applicable working conditions of the equipment. The impeller is installed on the horizontal pinion shaft inside the gearbox. In the figure below, each end of the pinion shaft is equipped with an impeller, which is a common configuration. However, it is equally common to have only one impeller installed on each pinion shaft.

2025-07-22 16:25:38

Surface treatment is a process method that artificially forms a surface layer with mechanical, physical and chemical properties different from those of the base material on the surface of the base material. The purpose of surface treatment is to meet the requirements of corrosion resistance, wear resistance, decoration or other special functions of the product. For metal castings, surface heat treatment of lead screws and guide rails is a commonly used surface treatment method.

2025-07-22 16:20:05

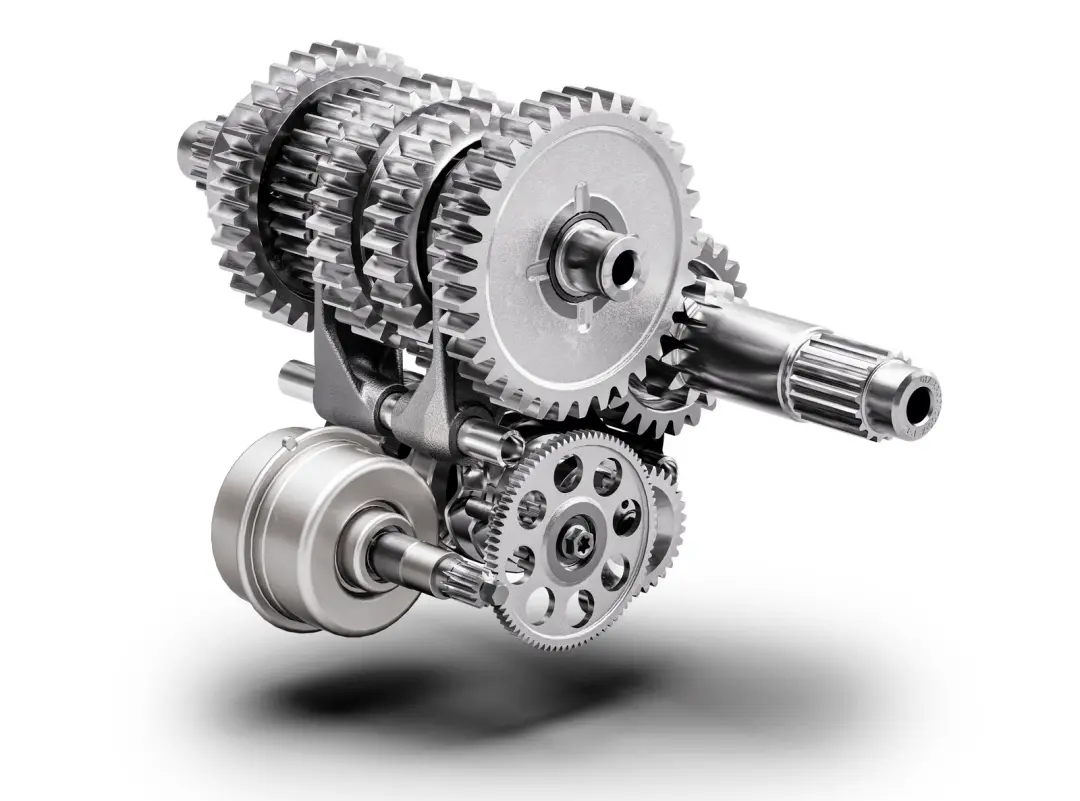

The main technical classifications of gear manufacturing processes can be divided into the following categories:

2025-07-17 17:00:12

In some cases, the corrosion resistance of stainless steel depends on the material series it belongs to. But generally speaking, the key lies in the content of the alloying element molybdenum. A rule of thumb is that the higher the molybdenum content, the stronger the corrosion resistance of the material. Molybdenum can also enhance the material's strength at high temperatures. Let's explore many commonly used stainless steel grades and determine their corrosion resistance levels based on the presence of molybdenum.

2025-07-17 16:50:01

The basic theories and methods of gear design mainly revolve around the geometric characteristics, mechanical properties, contact analysis, and lubrication conditions of gears. The following is a summary of the basic theories and methods of gear design based on the information I have gathered:

2025-07-15 16:14:30

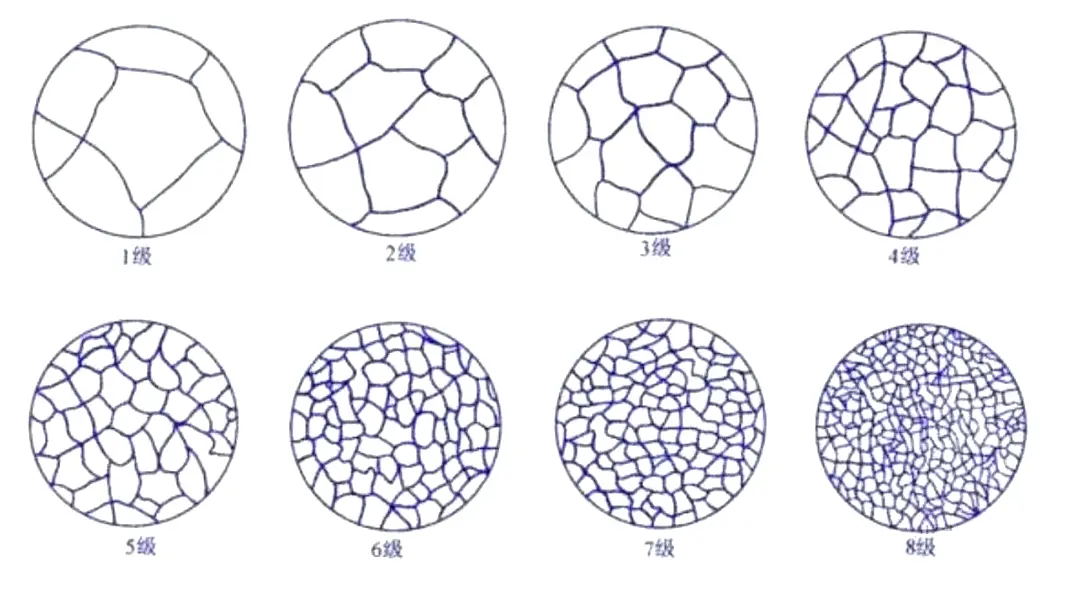

In the field of heat treatment of metallic materials, quenching is an extremely crucial and commonly used process. It involves heating the metal material to an appropriate temperature and maintaining it for a certain period of time, followed by cooling at an appropriate rate, thereby altering the internal microstructure of the material and significantly enhancing its mechanical properties, such as hardness, strength, and wear resistance. As an advanced form of quenching, ultrafine-grained quenching has attracted extensive attention in the field of materials science in recent years. Through specific technological means, it enables the metal material to obtain an ultrafine-grained microstructure after quenching, further endowing the material with superior comprehensive performance. It has demonstrated great application potential in numerous fields with extremely high requirements for material performance, such as aerospace, automotive manufacturing, and mold industry.

2025-07-15 16:11:13

In chemical heat treatment, all three methods aim to enhance the hardness, wear resistance, fatigue strength, and other properties of the surface of parts while maintaining the toughness of the core. They all fall under the category of chemical heat treatment. The following provides a detailed explanation of their differences and characteristics:

2025-07-11 16:00:00

367