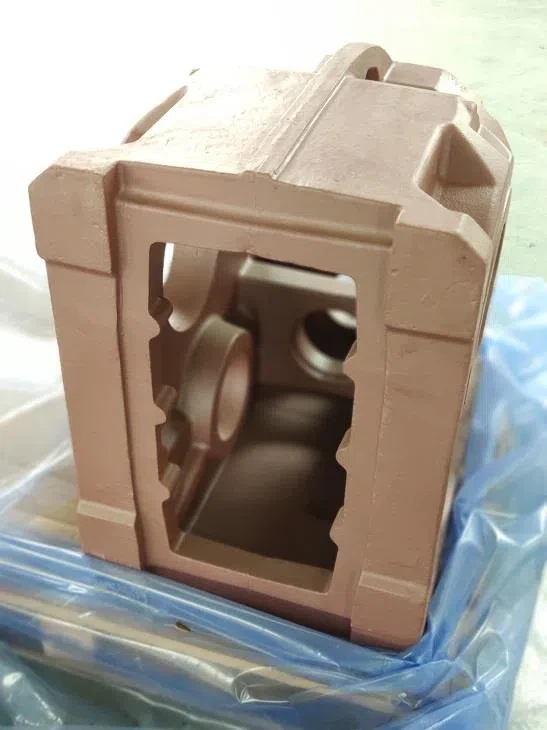

Gear Reducer Housing

Application:Gearbox/Gear Speed reducer

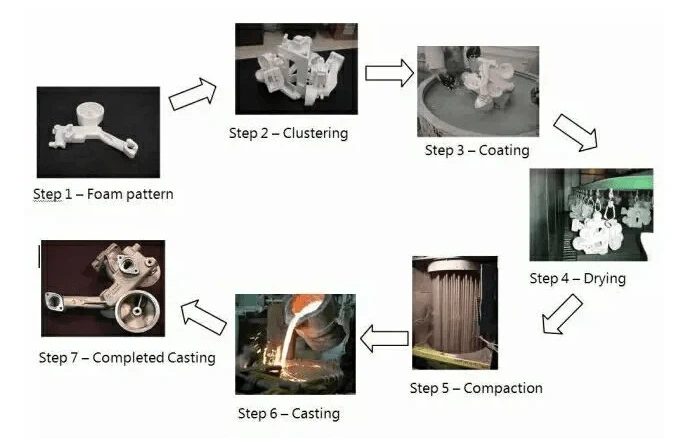

Production Process:Lost Foam Casting

Material:Cast Iron

Material Grade:As per requirement

Casting Tolerance:ISO 8062-CT8-10

Surface Roughness:Around Ra(μm)12.5

We are professional Machinery Manufactuar, we have the complete facilities for inspection, machining and heat treatment, as well as a mature supply chain of Carburization, Nitriding, Vacuum heat treatment and Surface treatment etc.

We provide different kinds of Gear Reducer Housings to meet the different needs of our customers. We also support customization, you can also customize according to your needs

Gear Reducer Housing is the basic part of the machine and parts, to combine the parts into a complete machine, keep their correct relative position and the exact geometrical tolerance of each other, and ensure the coordination of operation.

Technical Parameter

|

Application |

Gearbox / Gear Speed reducer |

|

Production process |

Lost Foam Casting |

|

Material |

Cast Iron |

|

Material Grade |

As per requirement |

|

Casting Tolerance |

ISO 8062 - CT8-10 |

|

Surface Roughness |

Around Ra (μm) 12.5 |

Product Display

|

|

|

| Gear Reducer Housing | Shell of speed reducer |

Different Form:

Common housings have various forms, like Machine tool spindle box, Gear speed reducer housing and gearbox housing. All kinds of housings have different shape and structure due to different functions.

|

|

|

| Speed reducer Housing | Gearbox Housing | Gearbox Casing |

|

|

|

| Gear Reducer Housing | Speed reducer Casing | Gear Reducer Casing |

Production Process

What is the main functions of Gearbox Housing?

As a protection device for the gearbox, the gearbox casing is crucial to the entire gearbox system.

- Protection: The gearbox housing provides a protective enclosure for the internal components of the gearbox, shielding them from external contaminants such as dust and moisture. This can effectively prolong the working life of the gearbox.

- Support: The gearbox housing also provides structural support for the gearbox components, maintaining their proper alignment and ensuring smooth operation.

- Heat Dissipation: The gearbox housing also plays a role in managing heat within the gearbox. Materials like aluminum, known for their thermal conductivity, can help dissipate heat generated during operation, preventing overheating and ensuring optimal performance.

- Noise Reduction: The housing also plays a crucial role in reducing noise generated by the operation of the gearbox.

In sum, the gearbox housing is a vital component of the gearbox system. Its design and material selection significantly influence the performance, durability, and overall effectiveness of the gearbox. Consequently, understanding the intricacies of gearbox housing is crucial for engineers in the field.

Machinery Processing of Gearbox Housing

►Casting: The gearbox housing is often produced through casting, which involves pouring molten metal or plastic into a mold. The mold is typically made of sand, clay, or metal. Casting allows for the production of complex shapes and large quantities of parts at a relatively low cost.

►Machining: After the casting process, the gearbox housing is machined to achieve its final shape and dimensions. Machining operations such as turning, milling, drilling, and grinding are used to remove excess material and create the necessary features and tolerances.

►Surface finishing: The surface of the gearbox housing is often finished to improve its appearance and performance. Processes such as polishing, buffing, sandblasting, or painting may be used to achieve the desired finish.

►Assembly: The gearbox housing is assembled with other components of the speed reducer gearbox, such as gears, bearings, and seals. Assembly may involve processes such as pressing, welding, or bolting.

Application of Speed Reducer Gearbox Housing

★Industrial machinery: Speed reducer gearbox housing is commonly used in industrial machinery such as conveyors, mixers, pumps, and heavy equipment. These applications require high torque and low-speed operation, which is achieved through the use of a speed reducer gearbox.

★Renewable energy: Speed reducer gearbox housing is used in wind turbines and solar tracking systems to convert the low-speed rotation of the rotor or tracking system to high-speed rotation of the generator or actuator.

★Marine: Speed reducer gearbox housing is used in marine applications such as propulsion systems and winches. In these applications, the gearbox provides the necessary torque to move heavy loads and adjust the direction of the vessel.

Products Test

►Dimensional inspection: This test involves measuring the dimensions of the machined part to ensure that it meets the required specifications and tolerances.

►Hardness testing: This test involves measuring the hardness of the machined part to ensure that it meets the required strength and durability requirements.

►Material analysis: This test involves analyzing the material properties of the machined part to ensure that it is the correct material and meets the required standards.

►Non-destructive testing (NDT): This type of testing involves using methods such as ultrasonic testing, magnetic particle inspection, or dye penetrant inspection to detect defects in the machined part without causing damage.

►Performance testing: This test involves testing the performance of the machined part in the actual application to ensure that it meets the required performance requirements.

►Magnetic particle inspection (MPI): This method uses magnetic fields and iron particles to detect surface and near-surface defects in the gear shafts, such as cracks or inclusions. The gear shaft is magnetized and then iron particles are applied to the surface. Any defects will attract the particles and produce a visible indication.

hotTags : Gear Reducer Housing,China, suppliers, manufacturers, factory, foundry, customized, buy, quotation, low price, high quality, high accuracy, high performance, free sample,accurate,OEM.