Knowledge

Seven major defects of ductile iron castings, could the root cause be the same? Seven major defects of ductile iron castings, could the root cause be the same?

Ductile iron castings play a crucial role in the mechanical manufacturing field due to their high strength and good toughness. However, casting defects are like "roadblocks" on the quality journey, causing many casting managers a great deal of trouble.

However, you might not expect that the root causes of the seven common types of defects in ductile iron casting production are all closely related to the selection and use of spheroidizing agents. Understanding the intrinsic connection between spheroidizing agents and defects is the key to improving casting quality and reducing scrap rates.

High-quality spheroidizing agent

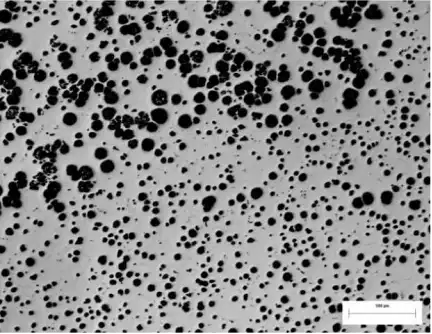

Abnormal Graphite Spheres

The roundness of graphite spheres directly affects the performance of ductile iron castings. Once irregular shapes such as lumps or tadpoles (i.e., abnormal graphite spheres) occur, the mechanical properties of the castings will decline significantly. Behind this, the residual amount of the spheroidizing agent is the key factor.

If the residual magnesium is too high, the growth pattern of spheroidal graphite will be disrupted, and tadpole-shaped graphite is likely to form. When the residual rare earth is excessive, "gray spots" - concentrated areas of fragmented graphite - will appear in high carbon equivalent molten iron. Insufficient spheroidizing elements or excessive titanium and aluminum in the molten iron will lead to the formation of vermicular graphite. Therefore, in production, the residual amount of the spheroidizing agent needs to be precisely controlled, and the composition of the molten iron should be adjusted accordingly to avoid the situation of "too much leads to chaos and too little leads to waste".

Graphite floating

In thick-walled ductile iron castings with hypereutectic composition, a dense graphite zone often appears at the top after pouring - this is graphite floating. Due to the lower density of graphite than that of molten iron, the graphite precipitated from hypereutectic molten iron will be upwardly aggregated by buoyancy, thus causing graphite floating.

Spheroidizing agent also plays an important role here. Increasing the residual magnesium content can reduce floating, as magnesium can increase the eutectic carbon content and balance the composition of molten iron; however, an excessive residual rare earth content will have the opposite effect, promoting the formation of burst-like graphite and exacerbating floating. In addition, controlling the pouring temperature and solidification time, in conjunction with the regulation of spheroidizing agent, can effectively solve this problem.

White Cast Iron Structure

The white cast iron structure is usually found in the surface layer where cooling is rapid in common cast iron. However, the reverse white cast iron structure does the opposite - the carbide phase is concentrated in the center of the medium cross-section, hot spots and other areas where cooling is relatively slow. This can lead to a hard and brittle core of the casting, making it difficult to process.

Excessive residual amount of spheroidizing agent is an important cause of white mouth. Rare earth and magnesium will increase the undercooling degree of the formation of ductile iron structure, and the "white mouth promoting" effect of rare earth is stronger than that of magnesium. Therefore, in the production of medium section castings, the addition amount of spheroidizing agent should be strictly controlled to avoid the occurrence of hard and brittle structure in the core.

Subcutaneous needle puncture

Subsurface pinholes are common gas porosity defects in ductile iron castings, mostly distributed beneath the casting surface. They not only affect the appearance but also may become stress concentration points, reducing the strength of the casting. These pinholes mainly contain hydrogen and also have a small amount of carbon monoxide and nitrogen mixed in.

When the residual magnesium content is too high, the ability of molten iron to absorb hydrogen from green sand increases, and the probability of porosity formation rises significantly. Meanwhile, if molten iron stays for a long time after spheroidization, gases such as hydrogen are difficult to escape, and the number of porosity will further increase. In production, the residual magnesium content should be controlled, the molten iron's stay time should be shortened, and the invasion of gases should be reduced.

Shrinkage cavities and porosity

Shrinkage cavities and porosity are holes formed in castings due to insufficient feeding during solidification. Shrinkage cavities are mostly found in the last solidified hot spots, while porosity consists of fine interconnected holes, both of which can weaken the load-bearing capacity of the casting.

Research findings indicate that the residual amount of spheroidizing elements is closely related to the occurrence of shrinkage cavities and porosity. When the residual magnesium and rare earth content is too high, it will increase the shrinkage tendency of molten iron, and the degree of porosity almost intensifies with the increase of spheroidizing element content. Therefore, only by reasonably controlling the dosage of spheroidizing agent and combining with riser design and other feeding measures can such defects be reduced.

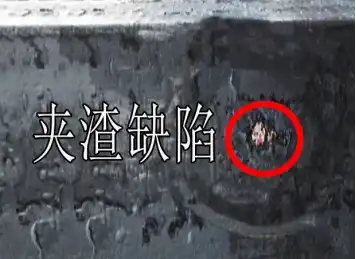

Black slag

The blocky or rope-like black slag that appears on the upper part of the casting (at the pouring position) not only affects the appearance but may also lead to local loose structure. The main component of black slag is magnesium silicate, which is formed by the reaction of MgO and SiO₂ in the molten iron.

The key to controlling black slag lies in regulating the magnesium content. Reducing the residual magnesium content can lower the amount of MgO produced, thereby reducing magnesium silicate; and rare earth elements, due to their strong affinity for oxygen, can react with oxygen preferentially, indirectly reducing black slag. In production, the ratio of magnesium to rare earth elements needs to be balanced, and the operation of skimming slag from molten iron should be strengthened.

Spheroidization Regression

Spheroidization regression will cause graphite to deteriorate from spherical to vermicular and flake, directly leading to the deterioration of casting performance. This is closely related to the spheroidizing agent: if the rare earth content in the spheroidizing agent is low and the addition amount is insufficient, the spheroidization effect is difficult to maintain; while if the molten iron stays too long after spheroidization, the residual magnesium content decreases, and sulfur elements "make a comeback", which will also aggravate the regression.

To prevent the decline of spheroidization in castings, a dual-pronged approach is necessary. On the one hand, high-quality spheroidizing agents should be selected to ensure the content and dosage of rare earths. On the other hand, the sulfur content of the original molten iron should be controlled. Low-sulfur molten iron can reduce the consumption of spheroidizing agents and prolong the effective time of spheroidization.

Summary

Spheroidizing agent is undoubtedly the "core additive" in the production of ductile iron parts, but its application is more like a delicate balancing art. To better master it and avoid defect troubles, the key lies in precisely controlling the residual amount of the spheroidizing agent and forming a synergy with the analysis of molten iron composition and the regulation of casting process.

Remember, spheroidizing agents are by no means a "panacea". Only by integrating them into a rigorous and coordinated technological system can obtain high-quality ductile iron castings.

Vigor has more than 20 years of experience and a professional team in the main casting processes. If you have any questions or any parts that need to be developed, please feel free to contact us at info@castings-forging.com