Knowledge

The Application and Advantages of 440C Alloy Steel Parts and 440C Gears and Shafts in the Automotive Industry

The Application and Advantages of 440C Alloy in the Automotive Industry

440C alloy, also known as stainless steel alloy 440C, is a high-carbon martensitic stainless steel that offers excellent hardness and wear resistance. This alloy is also known by other names such as X105CrMo17 or 1.4125 and is widely used in the automotive industry due to its outstanding performance. We will explore the various applications and advantages of 440C alloy in the automotive field.

What is 440C alloy?

AISI 440C is a high-carbon chromium steel with a martensitic crystal structure. It contains approximately 1.0% carbon and 17% chromium, making it one of the stainless steel alloys with the highest strength and hardness levels. The high carbon content enables 440C alloy bars to achieve a hardness of up to 60 HRC, making it an ideal choice for applications that require excellent wear resistance and high strength.

The Application of 440C Alloy in the Automotive Industry

Bearings: The automotive industry is one of the major consumers of 440C alloy. One of the most common applications of this alloy is in the production of bearings. Due to its high hardness and wear resistance, it can be used in the bearing industry where components are constantly under friction and wear. The steel used for bearings is the stainless steel alloy 440C to ensure that the bearings can work for a long time and withstand harsh working conditions.

Valve Components: Another important use of 440C alloy in the automotive industry is in automotive valve components. The special properties of the material, such as high corrosion resistance and heat resistance, make it suitable for engine valves and maintain the structure of the material at high temperatures.

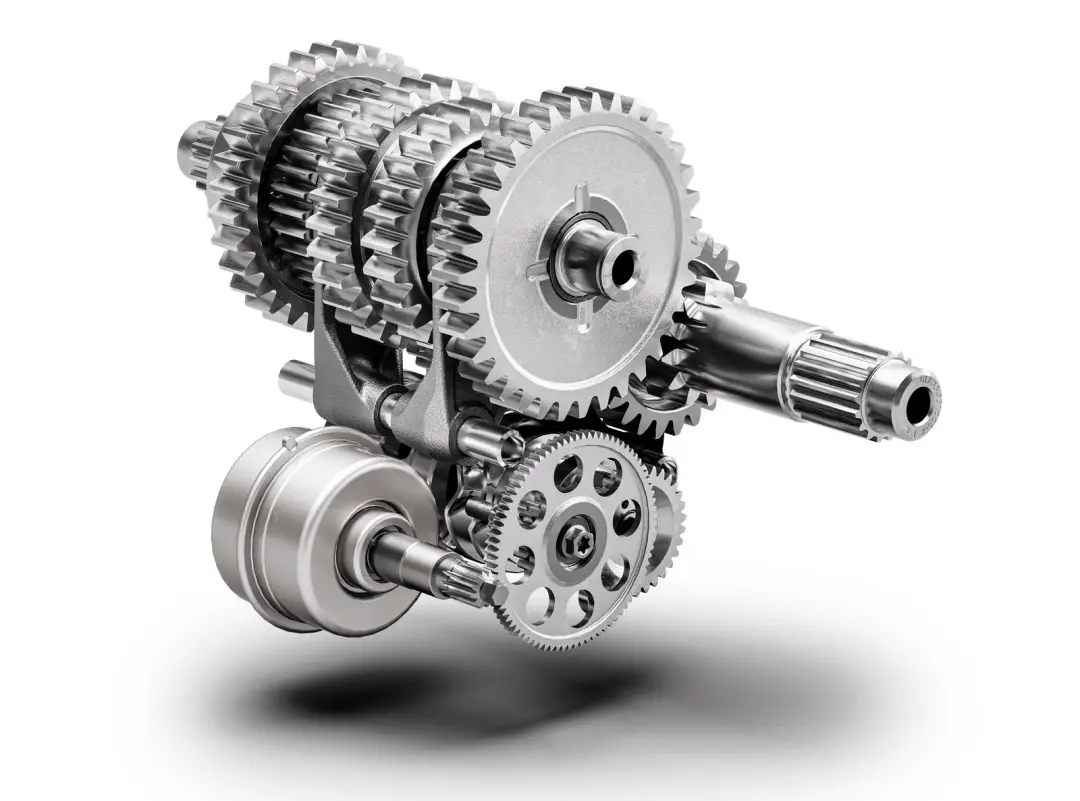

Gears and Shafts: 440C alloy bars are also used to manufacture gears and shafts. These components require materials that can effectively withstand stress and wear, and 440C fully meets these requirements. It has high strength and hardness, keeping gears and shafts strong and thus not requiring frequent replacement.

Cutting Tools and Surgical Instruments: Besides the automotive industry, this alloy is also used in the manufacture of cutting tools and surgical instruments. Due to its ability to maintain sharp edges and resistance to corrosion, it is very useful in these applications as it is practical and durable.

Advantages of 440C Alloy

Outstanding Hardness and Wear Resistance: The most notable advantage of 440C alloy is its excellent hardness and wear resistance. This characteristic is particularly beneficial in automotive applications where components are exposed to high levels of friction and mechanical stress.

Corrosion Resistance: Despite its high carbon content, 440C is highly resistant to corrosion. This makes it suitable for use in areas that may be exposed to moisture and chemicals, such as engine parts and bearings.

High Temperature Stability: 440C alloy rods are highly resistant to high temperatures and can be used in the manufacturing of engines and other high-temperature applications. This stability ensures that components do not deform or weaken under certain conditions.

Durability and Reliability: Components made with 440C are durable and highly reliable. This reduces the frequency of replacement and maintenance, thereby lowering costs for automotive manufacturers.

Versatility: Another advantage to mention is the versatility of AISI 440C. Due to its versatility and efficiency of use, this material is suitable for manufacturing automotive parts and surgical tools.

Conclusion

Therefore, 440C alloy is a high-performance material with multiple advantages for automotive applications. It features high hardness, wear resistance, corrosion resistance and high-temperature stability, and can be used in bearings, valves, gears and shafts.

Vigor has the professional team, complete system and equipment for producing and supply the 440C OEM metal products. If any thing we can help or any parts you need to develop, please feel free to contact us at info@castings-forging.com