Knowledge

How to understand "reduction of area"?

Key words: plasticity, reduction of area

Selecting appropriate materials is an indispensable part of the product development process.

Although there are numerous performance parameters for materials, the mechanical properties of materials are mainly considered, such as strength and hardness. Especially "strength" is often regarded as the most important parameter and involved in the structural stress analysis and calculation.

Parameters like "elongation after fracture", which seem insignificant, do not participate in the calculation, and thus (at least on the surface) this parameter seems to make no contribution to product design.

In fact, elongation after fracture is usually used as a reference index for designers to select materials. For instance, whether the designer requires the product to have a certain degree of ductility, and whether the designer demands that the failure under extreme conditions be brittle or plastic.

Similar to the "elongation after fracture" A, the "reduction of area" Z is also an indicator for judging the plasticity of materials.

So the question arises: since there are already indicators for judging the plasticity of materials, why go to the trouble of creating a "reduction of area"? It's like, if Zhu Di had already intended in his heart to let Zhu Gaoxu inherit the throne, why did he appoint Zhu Gaochi as the crown prince? Was he just bored or was there some hidden reason?

The elongation after fracture is not perfect.

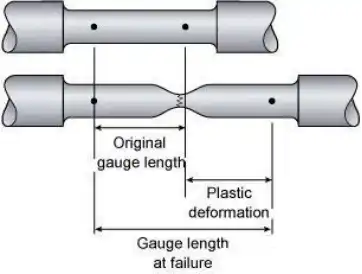

Figure 1 Measuring elongation after fracture

Familiar friends with material testing know that "elongation after fracture" refers to the ratio of the difference between the gauge length after fracture and the original gauge length to the original gauge length, that is:

A = (Lx - L0) / L0 Formula 1

From this formula, it can be seen that when people use Formula 1 to judge the plasticity of materials, they only look at the overall length change of the elongation after fracture, and they don't care at all about the shape of the specimen when it breaks - no matter how it breaks, as long as the elongation after fracture is long enough, then they consider the plasticity of this material to be good enough.

However, the problem precisely lies here.

From Formula 1, we can also see that, apart from the post-fracture gauge length Lx, the initial gauge length L0 is the reference parameter for calculating the elongation after fracture.

In other words, how much the elongation after fracture of the material is and whether the material has good plasticity or not depends on what it is compared with. From the perspective of elongation after fracture, it should be compared with the initial gauge length. Therefore, this means that it is very important to establish the specification for the selection of the initial gauge length.

Let's give an example for the friends to have a feel.

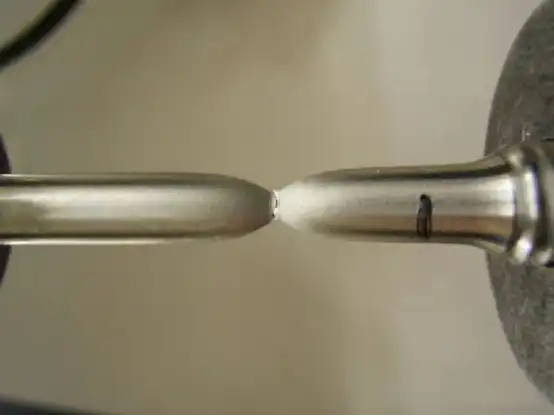

From a 10mm diameter wire rod, cut 1m and 10m long steel bars respectively and break them. According to experience, both steel bars will neck and break at some point. Except for the fracture area, the cross-section of the steel bars in other areas will hardly change, as shown in Figure 2: the further away from the necking area, the smaller the degree of cross-sectional change, and it is precisely the size change in this necking area that is the main reason for the elongation of the component.

Figure 2: No significant change in diameter away from the neck constriction area

This means that when a 1-meter-long steel bar and a 10-meter-long steel bar are each pulled to breaking point, their elongations are almost the same - that is, (Lx - L0) is the same.

Then, the elongation after fracture calculated based on Formula 1 and their respective original lengths L0 shows a tenfold difference! It is precisely for this reason that relevant standards stipulate that the specimens for measuring the elongation after fracture of materials must be processed to a specified length - that is, the initial gauge length cannot be changed arbitrarily. For details, please refer to GB/T 228.1.

This also seems to imply that the elongation after fracture of the material is related to the size of the specimen. However, this should not be the case. The reason is that whether we talk about strength, hardness, or even elongation after fracture, they should all be inherent properties of the material and should not be related to size.

For the reasons mentioned above, it is also why elongation after fracture A is often required to be marked with the specimen length, for example, A5 refers to the gauge length of five times the diameter.

It can be seen that if the plasticity of the material is evaluated by the elongation after fracture, it is necessary to require that the product size be large enough to process a certain length of specimen. This size restriction directly leads to the fact that small-sized products cannot be judged whether the material plasticity meets the requirements by testing the elongation after fracture.

The reduction of area compensates for this deficiency.

The reduction of area is remarkable

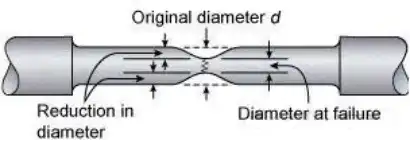

Figure 3 Determination of Sectional Reduction Rate

To calculate the reduction of area, it is first necessary to measure the original cross-sectional area A0 of the specimen and the cross-sectional area Ax at the fracture. Then, take the difference between the two and divide it by A0, that is:

Z = (A0 - Ax)A0 Formula 2

From this formula, it can be seen that the reduction of area of the material has no direct relationship with the length of the specimen. In other words, no matter how long the specimen is, as long as the original cross-sectional area and the cross-sectional area at the fracture can be measured, the reduction of area can be calculated.

The 1m steel bar and the 10m steel bar mentioned above, since the necking area changes in the same way, their cross-sectional reduction rates are the same.

This also aligns with our understanding of material properties - the performance parameters of materials should be independent of the size of the components.

In addition, the reduction of area measures the change in the cross-sectional area at the fracture, which compensates for the deficiency of the elongation after fracture that only assesses the plasticity of the material as a whole while ignoring local deformation. Engineers can use these two parameters to comprehensively evaluate the material's performance.

Vigor has more than 20 years experience and the professional team in producing castings, forgings, CNC machined parts, we know point improve metal parts performance on different materials and different structure metal parts. If you have any question or any parts need to be developed, please feel free to contact us at info@castings-forging.com