Forging production includes free forging, die forging, sheet metal stamping and metal extrusion, which is an important part of metal pressure processing. Free forging is an operation carried out on a forging hammer (or press), where the up and down movement of the hammer head (or die block) causes the heated ingot (or billet) to be compressed in height (or thickness) and freely elongated and widened in the horizontal direction. Various forging processes are adopted to obtain the required shape and size of the forged part, as shown in Figure 1a. Die forging involves placing the heated billet in a die cavity of a fixed shape to deform it. The die cavity walls restrict the free movement of the metal. When the die forging process is completed and the metal fills the die cavity, the desired shape and size are obtained. Sheet metal stamping uses sheet metal or strip metal, in a cold state, on a press, where the interaction between the punch and the die is used to stamp out the products or parts we need, as shown in Figure 1c. Extrusion involves heating the metal ingot (or billet), placing it in an extrusion cylinder, and under the action of the extrusion rod, the metal flows out from the die hole at the other end of the extrusion cylinder, obtaining various profile sections with irregular cross-sections, tubes and bars. Moreover, some cross-sectional shapes cannot be obtained by rolling methods.

2025-07-11 15:58:20

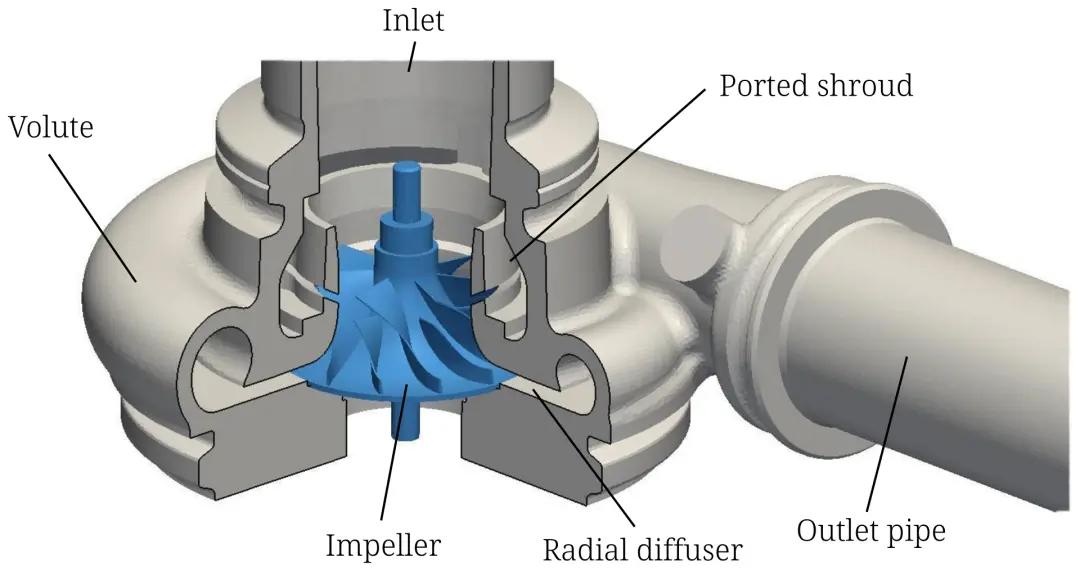

Centrifugal compressors are widely used in gas transmission, power generation, and chemical engineering, among other fields. The design of their blades is crucial to performance and efficiency. This article compiles the provided user information, references engineering principles and the latest research, to ensure the comprehensiveness and accuracy of the content.

2025-07-09 15:03:02

Steel C45 and 40Cr are two commonly used medium carbon steels that are widely applied in mechanical manufacturing. However, there are significant differences in their chemical composition, properties, and applicable scenarios. The following is a detailed comparison:

2025-07-09 14:55:35

The manufacturing process involves multiple steps, with the goal of obtaining parts that meet requirements for dimensional accuracy, shape accuracy, positional accuracy, surface roughness, surface hardness, and microstructure. The process flow depends on the material, batch size, precision requirements, and structural characteristics (integral vs. assembled).

2025-07-09 14:45:43

When choosing materials, the core considerations are strength, toughness, wear resistance, impact resistance, machinability and cost. Heat treatment is the key to achieving high performance of the materials.

2025-07-03 18:50:09

Gear Reducer Housing also named Gear reducer Casting, the Main Production Processes details are as following:

2025-07-03 18:40:48

Non-metallic inclusions, which may sound like "impurities" in steel, are actually extremely harmful! They are non-metallic compounds such as oxides, sulfides, and silicates that remain in the metal matrix during steelmaking and casting processes. Just like "blood clots" in the human body, they can disrupt the uniformity of materials and become the "culprits" of pressure vessel failure! According to the GB/T 10561 standard, non-metallic inclusions are classified into five types: A (sulfides), B (alumina), C (silicates), D (globular oxides), and DS (single large inclusions). Each type is further divided into grades 0.5 to 5 based on length or quantity (the higher the value, the greater the hazard). 、

2025-06-27 15:49:22

The selection of different structures, materials, and manufacturing processes for gear reducer housings is crucial to their performance (strength, rigidity, sealing, vibration and noise reduction, heat dissipation), cost, weight, and service life. The following is a detailed analysis:

2025-06-27 15:44:08

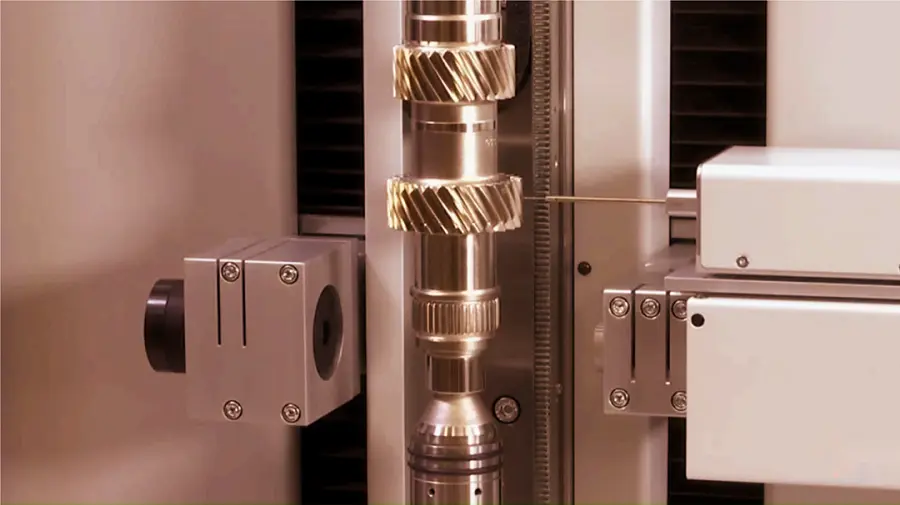

Let's systematically sort out the classification, common materials and production processes of gear shafts. Gear shafts are key mechanical parts that integrate gears and shafts in one design and manufacture, used for transmitting power and motion.

2025-06-27 15:22:44

Metal forming methods are an important part of part design and a matter of great concern to manufacturers. Today, we will take you to explore the major metal forming processes: casting, plastic forming, machining, welding, powder metallurgy, metal injection molding, semi-solid metal forming, and 3D printing.

2025-06-26 17:35:37

Common impurity elements in steel include phosphorus, sulfur, hydrogen, nitrogen and oxygen. Under normal circumstances, these elements have a detrimental effect on the properties of steel. However, some of them can play a beneficial role under specific conditions and become alloying elements.

2025-06-26 17:29:57

Alloying elements in steel

2025-06-26 17:19:41

367