Knowledge

The Threat of Non-metallic Inclusions to Pressure Vessels and Pressure Vessels Parts

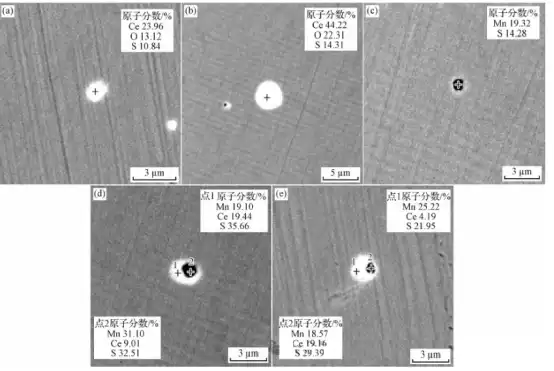

The microstructure of typical non-metallic inclusions in steel

I. What are Non-metallic Inclusions?

Non-metallic inclusions, which may sound like "impurities" in steel, are actually extremely harmful! They are non-metallic compounds such as oxides, sulfides, and silicates that remain in the metal matrix during steelmaking and casting processes. Just like "blood clots" in the human body, they can disrupt the uniformity of materials and become the "culprits" of pressure vessel failure! According to the GB/T 10561 standard, non-metallic inclusions are classified into five types: A (sulfides), B (alumina), C (silicates), D (globular oxides), and DS (single large inclusions). Each type is further divided into grades 0.5 to 5 based on length or quantity (the higher the value, the greater the hazard).

II. The True Faces of the Four Major Types of Inclusions

|

Type |

Characteristic Components |

Formal Characteristics |

Hazard Level |

|

A Type |

MnS、FeS |

Gray striped, highly malleable, extends after rolling |

★★☆ |

|

B Type |

Al₂O₃、MgO·Al₂O₃ |

White clustered brittle particles, prone to causing cracks |

★★★ |

|

C Type |

SiO₂·MnO etc. |

Gray-black chain-like or spherical, softens at high temperatures |

★★☆ |

|

D Type |

CaO·Al₂O₃ |

Tiny spherical, dispersed distribution reduces toughness |

★★☆ |

III. Why is there "Zero Tolerance" for Inclusions in Pressure Vessels?

Pressure vessels store flammable, explosive and toxic media. Once they fail, the consequences would be unimaginable! The three major crimes of non-metallic inclusions are as follows:

Crack initiation point: Brittle oxides (such as Al₂O₃) become the source of cracks under stress;

Accelerating corrosion: Sulfides (MnS) react with the medium to induce local corrosion;

Low-temperature embrittlement: Nitrides (TiN) increase the brittleness of the material at temperatures below -50℃.

Application of GB/T 10561 in Pressure Vessels:

High-pressure vessels (P ≥ 10MPa): Class A ≤ 1.5 grade, Class B ≤ 1.0 grade;

Low-temperature vessels (T ≤ -20℃): Single particle inclusions of DS class ≤ 0.5 grade;

Toxic medium vessels: Total inclusion grade number ≤ 2.5 grade.

IV. How does the pressure vessel industry control inclusions?

1. Upgrading of smelting process

Vacuum deoxidation: Reduce the oxygen content of molten steel to below 15ppm to minimize the formation of oxides; Calcium treatment: Add calcium alloy to convert Al₂O₃ into liquid calcium aluminate (12CaO·7Al₂O₃), facilitating their removal by floating.

2. Comprehensive detection and monitoring

Microscopic rating: Quantitative analysis of inclusions in accordance with GB/T 10561 (observed at 100x magnification); Ultrasonic flaw detection: Detect macroscopic inclusions (such as DS type), with a sensitivity of Φ0.8mm equivalent defect.

3. Typical case - Steel for LNG storage tanks

Requirements: Impact energy at -162°C ≥ 100J, inclusion grade ≤ 1.5; Countermeasures: Adopt RH vacuum refining + electromagnetic stirring, with an inclusion removal rate exceeding 90%!

V. Future Trends: Intelligent Inspection and Process Optimization

AI-based Metallographic Analysis: Huawei Cloud and Baosteel jointly developed an intelligent inclusion rating system with an accuracy rate of over 95%.

Targeted Inclusion Control: Predict the inclusion precipitation behavior through thermodynamic calculations (such as FactSage software).

Conclusion

Although non-metallic inclusions are small, they are the "Achilles' heel" of pressure vessel safety! Only by strictly adhering to the GB/T 10561 standard and implementing strict quality control from smelting to inspection can "Made in China" pressure vessels support a trillion-yuan industry!

China Vigor has more than 20 years of experience in the metal smelting, pouring, casting, and forging field. If you have any questions, demands, related parts development, or to improve your supply chain, please feel free to contact us at info@castings-forging.com