Knowledge

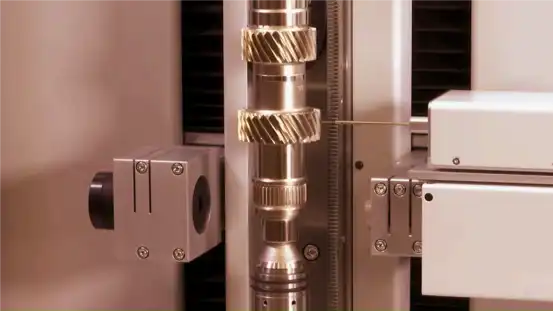

Gear Shaft (Part Two)

Gear Shafts Materials Selection

When choosing materials, the core considerations are strength, toughness, wear resistance, impact resistance, machinability and cost. Heat treatment is the key to achieving high performance of the materials.

1. Carbon Steel:

- Common grades: 45 steel is the most widely used medium carbon steel.

- Characteristics: Low cost, good machinability, and moderate comprehensive mechanical properties. Suitable for medium loads and not too high speeds.

- Heat treatment: Quenching and tempering (quenching + high-temperature tempering) to obtain good comprehensive mechanical properties (strength, toughness, plasticity). The surface hardness is usually not high, and the wear resistance is average.

- Applications: Medium and small-sized gear shafts in ordinary machine tools, agricultural machinery, and reducers where the load is not particularly large.

2. Alloy Structural Steel:

- Common grades:

Medium carbon alloy steel: 40Cr, 35CrMo, 42CrMo (extremely widely used)

Low carbon alloy carburizing steel: 20CrMnTi (main carburizing quenching steel grade), 20CrMo, 20CrNiMo

- Characteristics:

Medium carbon alloy steel: Contains alloy elements such as Cr, Mo, Mn, Ni, etc., with good hardenability, and superior strength, toughness, and wear resistance compared to carbon steel. After quenching and tempering, it has excellent comprehensive mechanical properties. It is an important material for medium and high-speed, heavy-load gear shafts.

Low carbon alloy carburizing steel: After carburizing and quenching on the surface, it can obtain a high-hardness surface layer (HRC 58-62, extremely wear-resistant) and a tough core (HRC 33-48, impact-resistant). The tooth surface has extremely high contact fatigue strength and wear resistance, and good impact resistance. It is the standard material for automotive gearboxes, high-speed heavy-load gearboxes.

- Applications:

Quenched and tempered alloy steel: Main shafts and transmission shafts in construction machinery, heavy machine tools, and marine power equipment.

Carburizing steel: High-precision, high-speed heavy-load gear shafts in automobiles, aircraft engines, precision machine tools, and mining hoisting equipment.

3. Stainless Steel:

- Common grades: Austenitic stainless steel such as 304, 316; martensitic stainless steel such as 420C, 17-4PH.

- Characteristics: Good corrosion resistance, suitable for use in humid and corrosive environments.

- Applications: Food machinery, chemical equipment, medical equipment, marine deck machinery, and other applications requiring corrosion resistance. The strength is generally lower than that of high-quality alloy steel.

4. Cast Iron:

- Characteristics: Low cost, good casting performance, and certain vibration damping, but poor strength, toughness, and impact resistance.

- Applications: Generally only used in unimportant, open, and low-speed transmission situations, and rarely used.

5. Ductile Iron:

- Common grades: QT600-3, QT700-2, etc.

- Characteristics: Better strength, toughness, and wear resistance than gray cast iron, while maintaining good casting performance.

- Heat treatment: Isothermal quenching can be performed to improve performance.

- Applications: Suitable for large-sized, complex-shaped, medium-load, smooth operation, cost-sensitive, and wear-resistant situations, such as large reducers in agricultural machinery and mining equipment.

Summary of Material Selection Principles

Strength and hardness: Ensure that the gear tooth surface has sufficient contact fatigue strength and bending fatigue strength, and the shaft has sufficient torsional strength and stiffness.

Wear resistance: Reduce operational wear and extend service life (carburizing steel, surface quenching, nitriding treatment solves this problem).

Impact toughness: Required when subjected to impact loads.

Heat treatment processability: The material should exhibit good hardenability and be amenable to controllable deformation.

Cost: Pursue economy while meeting performance requirements.

Material Category, Typical Grade, Main Characteristics, Typical Heat Treatment, Typical Applications

Carbon Steel 45 Low cost, good machinability, moderate comprehensive performance Quenching and tempering (HRC 22-34) Medium load, not too high speed general machinery Alloy structural steel: 40Cr, 35CrMo. It features excellent comprehensive performance, high strength, and toughness. Heat treatment: quenching and tempering (HRC 28-38). Applications: medium and high-speed, heavy-load scenarios (main material for general machinery).

Alloy carburizing steel: 20CrMnTi, 20CrMo. It has high surface hardness, high wear resistance and good core toughness. Heat treatment: carburizing, quenching (surface HRC 58-62). Applications: critical gears and shafts in automobiles, precision machine tools, etc. under high-speed and heavy-load conditions.

Stainless steel: 304, 316, 420C. It has good corrosion resistance. Heat treatment: solution treatment or quenching and tempering. Applications: humid and corrosive environments (medical, food machinery).

Ductile iron: QT600-3, QT700-2. It has good castability, shock absorption and noise reduction, and low cost. Heat treatment: normalizing or isothermal quenching. Applications: complex castings under low-speed and medium-load conditions (agricultural machinery large gears).

|

Material category |

Standard grades |

main features |

Typical heat treatment |

Appropriate occasions |

|

Carbon steel |

45 |

Low cost, good processability, medium comprehensive performance |

Tempering (HRC 22-34) |

General machinery with medium load and low speed |

|

Alloy constructional steel |

40Cr,35CrMo |

Excellent comprehensive performance, high strength and toughness |

Tempering (HRC 28-38) |

Medium and high speed, heavy load occasions (main material of general machinery) |

|

Alloy carburized steel |

20CrMnTi,20CrMo |

High surface hardness, high wear resistance, and good toughness of the core |

Carburizing and quenching (surface HRC 58-62) |

High-speed heavy-load key gear shafts for automobiles and precision machine tools |

|

Stainless steel |

304,316,420C |

Good corrosion resistance |

Solution or quenching and tempering |

Damp and corrosive environment (medical, food machinery) |

|

Nodular cast iron |

QT600-3,QT700-2 |

Good casting, shock absorption, and noise reduction, low cost |

Normalizing or isothermal quenching |

Complex castings with low speed and medium load (large gears of agricultural machinery) |

If you have any questions, demands, need new parts to be developed or to improve your supply chain, please feel free to contact us at info@castings-forging.com