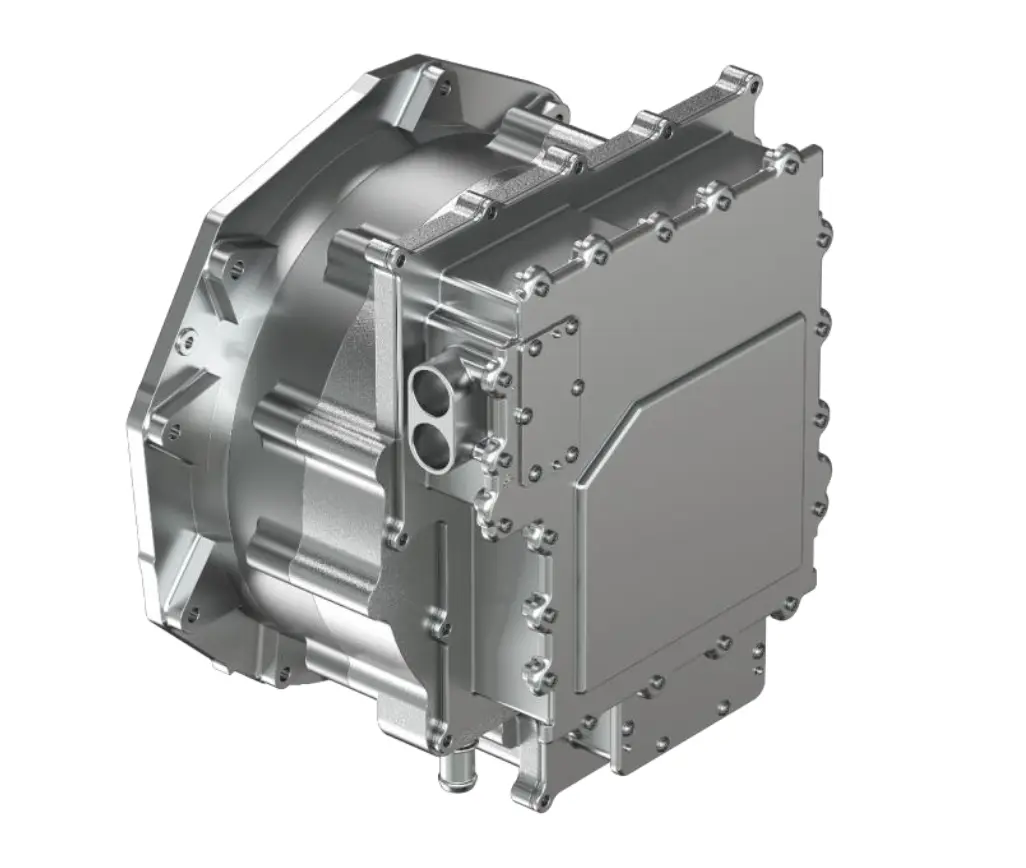

Axial flux motors began to be discussed for application in the main drive motors of new energy vehicles a few years ago. However, due to manufacturing difficulties and cost reasons, car manufacturers have been waiting and observing. But at this year's Shanghai Auto Show, many companies showcased axial flux motors. Let's take a look together. Actually, I am quite optimistic about the application scenarios of axial flux motors as range extenders, as they can be made relatively small. Coincidentally, Chery and Star Drive Technology have already made corresponding practices in this regard.

2025-05-13 14:29:05

SA516Gr70 is a type of steel for low and medium temperature pressure vessels in the American standard, and its execution standard is ASME SA516/SA516M. There are also SA516Gr65, SA516Gr60, and SA516Gr55 in the standard. Due to its excellent steel plate performance, it is widely used in the industry.

2025-05-09 15:04:22

What are the differences between involute gears and involute splines? Have you ever had such a question? In fact, both are involute tooth profiles, and the tooth-making methods are also quite similar, so the differences are indeed not significant. However, the different functions of the two still determine some parameter differences. For example, the topic we are discussing today: Why is the pressure angle of gears commonly 20° while that of splines is commonly 30°?

2025-05-09 14:59:12

Steel containing a certain amount of special alloy elements is called alloy steel. After adding a certain amount of alloy elements to steel, it acquires certain special mechanical and physical-chemical properties to meet the comprehensive needs of national economic development.

2025-05-09 14:33:47

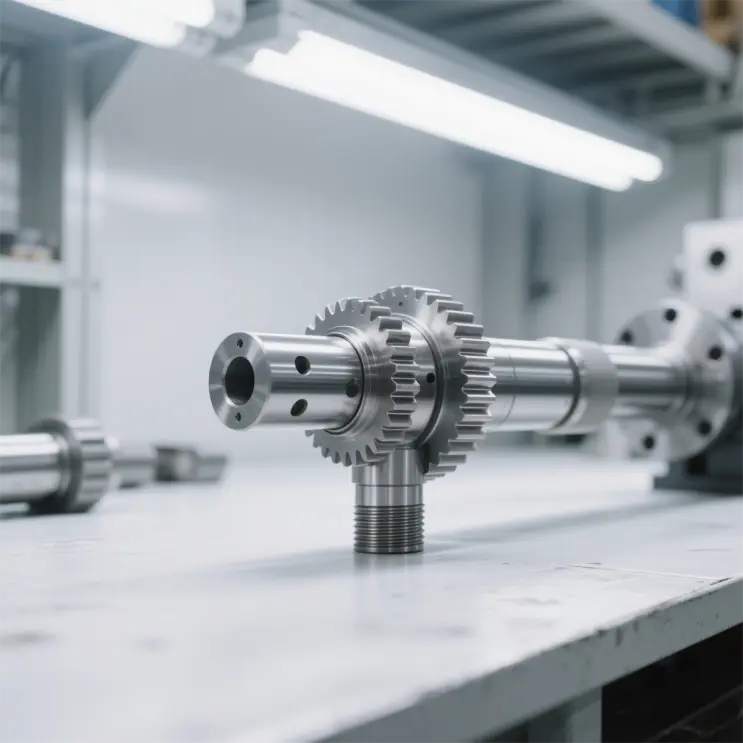

Spline shaft is a type of mechanical transmission, mainly used for transmitting mechanical torque. There are longitudinal keyways on the outer surface of the shaft, and the rotating parts fitted on the shaft also have corresponding keyways, which can maintain synchronous rotation with the shaft. The application, material selection and inspection points of spline shaft are as follows:

2025-04-29 17:39:05

The material of the motor shaft is usually made of high-strength alloy steel or stainless steel. At the same time, attention should be paid to the magnetic properties and precision requirements of the material.

2025-04-29 17:37:36

In the operation of various mechanical equipment, gear shafts, as key components of the transmission system, directly affect the operational efficiency and stability of the entire machinery. Different mechanical equipment have diverse working conditions and performance requirements, and conventional standard gear shafts are difficult to fully meet these needs. Therefore, custom gear shaft processing has emerged as a key solution to unlock higher transmission efficiency and more reliable working conditions.

2025-04-29 17:36:16

The differences and application environments between spur gears and helical gears are as follows

2025-04-29 11:16:28

2025-04-29 11:12:58

During the production process of die-castings, various defects may occur, which can affect the appearance, dimensional accuracy, and mechanical properties of the castings. The following are some common types of defects in die-castings

2025-04-29 11:05:29

Die casting machines and mold technology are the foundation for achieving efficient and precise die casting production. Die casting machines can be classified into two major categories based on their working principles: hot chamber and cold chamber, each with its unique technical features and application scope.

2025-04-29 10:52:14

Precision castings are generally complex in shape, which brings certain difficulties to the casting process. When using filters, they are mostly placed at the gate position. In practical applications, depending on different castings and requirements, the following methods can be adopted:

2025-04-24 17:54:13

367