Knowledge

Why is the Pressure Angle of Gears Usually 20° While that of Splines is Usually 30 °?

What are the differences between involute gears and involute splines? Have you ever had such a question? In fact, both are involute tooth profiles, and the tooth-making methods are also quite similar, so the differences are indeed not significant. However, the different functions of the two still determine some parameter differences. For example, the topic we are discussing today: Why is the pressure angle of gears commonly 20° while that of splines is commonly 30°?

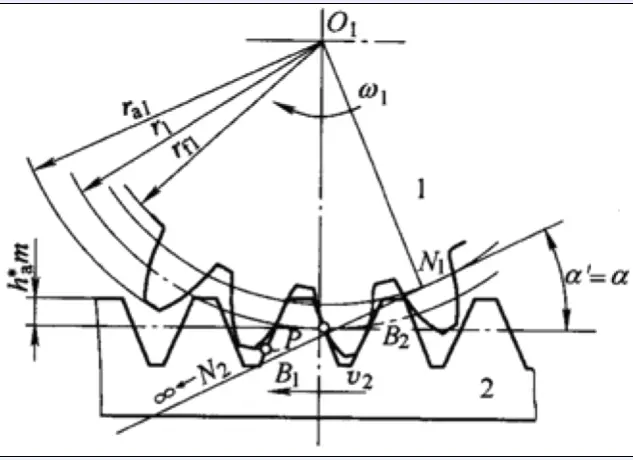

Before discussing the differences in pressure angles between the two, let's first take a look at the differences in their functions and applications. Gears are mainly used to transmit power and motion, achieving speed/torque conversion, emphasizing transmission efficiency and precision; splines, on the other hand, are used for the circumferential fixed connection between shafts and hubs, serving both power transmission and centering functions. Therefore, in terms of tooth profile design, the tooth profile of gears focuses on smooth transmission, even contact stress distribution, and balanced load-carrying capacity, while the tooth profile design of splines pays more attention to load-carrying capacity and self-centering characteristics.

Another difference between the two lies in that: a spline uses all the teeth or grooves simultaneously to transmit torque, while a gear transmits torque each time by using only one or two teeth depending on the degree of overlap.

The influence of different pressure angles:

1. An increase in the pressure angle will thicken the tooth root, which is beneficial to the bending strength and contact strength of the tooth root. However, it will thin the tooth tip, and usually, the tooth tip height needs to be reduced to avoid the tooth tip being too thin.

2. According to the calculation formula of the overlap ratio, the size of the pressure angle affects the size of the tooth tip angle and the meshing angle, thereby influencing the size of the overlap ratio. Generally speaking, the overlap ratio decreases as the pressure angle increases.

3. An increase in the pressure angle will also increase the radial component load. For involute gears, as mentioned earlier, we need to pay attention to the smoothness of transmission, the distribution of contact stress, and the balance of load-carrying capacity. Although a larger pressure angle can theoretically increase the tooth root strength of a single tooth, the overlap ratio will decrease, affecting the smoothness of transmission and offsetting some of the strength. At the same time, the radial load brought by the pressure angle during gear meshing is directly borne by the shaft and bearings. A larger pressure angle will also increase the load on the bearings and shaft, and thus larger size specifications need to be selected, increasing the volume and cost. Therefore, gears cannot adopt too large a pressure angle. 20° is a moderate choice. When low noise and high overlap ratio are required and load is not a key concern, a smaller pressure angle can be selected.

Unlike gears, splines engage all their teeth at once, and the radial forces generated by the pressure angles can cancel each other out. This is why involute splines can self-center. Additionally, as we know from the previous functional description, splines are mainly used to transmit loads and are not concerned with the degree of overlap. Therefore, the strength of the tooth roots is the key focus. A larger pressure angle can effectively enhance the strength of the teeth, which is why a 30° pressure angle is chosen, larger than that of gears. In standards, splines also have larger pressure angles available, such as 37.5° and 45°, etc. The larger the pressure angle, the greater the load capacity, but the lower the tooth height. They are usually made by cold forming processes and are suitable for thin-walled parts. A 30° pressure angle is typically produced by cutting (such as hobbing, broaching, etc.), and compared to splines with larger pressure angles, it can better balance transmission efficiency and strength, especially in applications requiring sliding or floating connections (such as sliding gears in gearboxes), and thus is more widely applicable.

If you have any question, demand, new parts need to be developed or improve your supply chain, please feel free to contact us info@castings-forging.com