Knowledge

【2025 Shanghai Auto Show】Those Impressive Axial Flux Motors

Axial flux motors began to be discussed for application in the main drive motors of new energy vehicles a few years ago. However, due to manufacturing difficulties and cost reasons, car manufacturers have been waiting and observing. But at this year's Shanghai Auto Show, many companies showcased axial flux motors. Let's take a look together. Actually, I am quite optimistic about the application scenarios of axial flux motors as range extenders, as they can be made relatively small. Coincidentally, Chery and Star Drive Technology have already made corresponding practices in this regard.

1. Valeo

At this exhibition, Valeo showcased a thinner, smarter and more efficient axial flux generator and announced a partnership with Disc Dynamics to develop a new generation of products. The two sides will combine Disc Dynamics' structural expertise with Valeo's leading technologies in inverters and other areas to accelerate the application of electrification solutions in extended-range electric vehicles.

Valeo's axial flux two-in-one generator system achieves up to 50% size reduction and 97% efficiency.

2. Pangood

At the 2025 Shanghai Auto Show, PanGu Power showcased two new axial flux motors with ultra-high speed and ultra-high power density. Among them, the peak power of the PanGu ICD306K motor is 306kW, with a maximum speed of 18,000 rpm, an effective power density greater than 21kW/kg, and an effective torque density of 32.5N·m/kg.

The release of the Pankhu ICD306K motor has raised the peak speed of axial flux motors to a brand-new level of 18,000 rpm, signifying that Pankhu has "reached a new pinnacle" in the design and manufacturing process of axial flux motors.

The distributed drive assembly that adopts two hub ICD306K axial flux motors has its axial dimension controlled within 500mm, and the total weight of the entire system is effectively controlled within 95 kilograms. The peak power reaches 612kW, and the power density of the drive assembly exceeds 6.4kW/kg, which is at the leading level in the industry.

At the auto show, Panhub also showcased the dual-motor distributed drive assembly PDS560DM, which is centered around the ICD280K drive motor. Compared to similar products on the market that typically have an axial dimension of 700-800mm, the axial dimension of the PDS560DM is less than 500mm. It has a peak power of 560kW and can provide a more powerful power output solution for vehicles within a limited layout space, demonstrating a very obvious differentiation advantage.

3 SHedrive

This axial flux motor, with its high power density and compact lightweight design (reducing volume and weight by 30% - 50%), high efficiency and low iron loss characteristics (broad efficient range to meet range extender requirements), as well as high torque density and rapid dynamic response capabilities, is an ideal choice for the generator system of new energy range extenders. Its excellent heat dissipation performance, modular integration convenience (can be directly connected to the internal combustion engine), and low noise and vibration performance significantly enhance the energy conversion efficiency, spatial layout flexibility, and NVH performance of the range extender system, effectively reducing fuel consumption and emissions, and meeting the core demands of electric vehicles for lightweight, energy conservation, and high reliability.

- Voltage platform: 350V;

- Peak power: 91kW;

- Peak torque: 240Nm;

- Maximum speed: 6000rpm;

- Operating voltage: 260V - 420V;

- Maximum motor efficiency: 95.6%

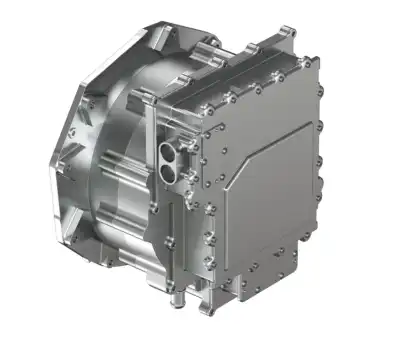

4. Schaeffler

Schaeffler also showcased a compact high-performance axial flux motor with a peak power of 250kW, peak torque/continuous torque of 480Nm/350Nm, weighing only 33kg, and a moment of inertia of 0.036kgm². It is reported that this motor adopts electronic direct oil cooling, featuring excellent heat dissipation efficiency. Meanwhile, it uses a high-efficiency air-cooled yokeless rotor to achieve high power density and outstanding dynamic response within a size of 306mm in diameter and 93mm in length.

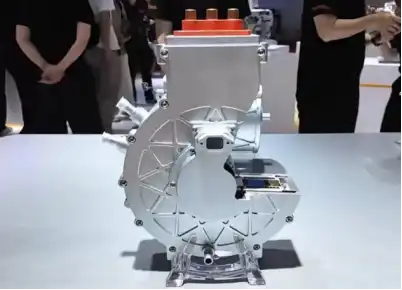

Chery also showcased a range-extending technology system - the Kunpeng Golden Range-Extending CEM. This system features an axial flux oil-cooled motor as the generator, the same motor technology used in Koenigsegg Regera/Gemera and Rimac Nevera. Axial flux motors are known for their high efficiency, high power density, and lightweight characteristics. Combined with Chery's self-developed Kunpeng Tianheng engine, the CEM system not only enables flexible power layout but also significantly enhances the performance of the range-extending system. The application in both water and land vehicles is the most appropriate demonstration of this.

5. Chery

The exhibit at Chery's show last October has already been integrated with an engine to become a complete range extender just half a year later. It will be an important development direction for future range extenders.

6. CATL

CATL showcased its high-safety flagship skateboard chassis, the "Panshi Chassis", at the auto show. It is equipped with an axial flux distributed electric drive system - the AMDS dual-motor distributed drive (axial flux motor).

It supports a peak torque of 6200Nm at the wheel end and a peak power of 500kW, capable of delivering a maximum continuous power output of 320kW. It can achieve a 0-100km/h acceleration in less than 5 seconds and a top speed of 280 kilometers per hour. Notably, the motor measures 235mm in size, with a system height of 320mm in the Z direction, a width of only 485mm in the Y direction, and a length of 430mm in the X direction.

In the same space, the system's power has been increased by a factor of two or more, and the torque has been enhanced by over 50%. This is the result of adopting axial flux technology to meet the demands of specific application scenarios.

Main parameters and technical features:

◽ Peak power: 250 kW × 2

◽ Peak torque: 350 - 435 Nm × 2

◽ Maximum speed: 18,000 rpm

◽ Envelope size: 430 × 485 × 320

◽ System output peak torque: 6,200 - 10,000 Nm

◽ Wheel-end speed: 1,500 - 2,000 rpm

◽ Torque vectoring control: Available

◽ Integrated axial flux disc motor, saving Y-direction space

◽ Integrated SiC 800Vdc dual-module power components

◽ Integrated torque vectoring control module, independent control of left and right wheel output, achieving a smaller turning radius and better cornering handling

◽ Combined with multi-link + air spring structure, ensuring both driving performance and comfort simultaneously

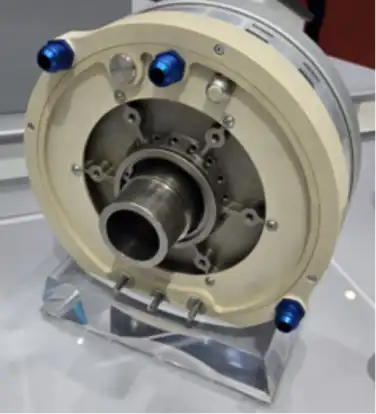

7. Voyah

During the auto show, Voyah officially released its L3-level intelligent architecture technology - Tianyuan Intelligent Chassis. Among them, the Qingyun L3-level intelligent safety driving platform adopts axial flux motor technology. The axial flux motor independently developed by岚图 has a peak torque of 680 N·m per unit, weighs only 28 kg, has a volume of 9.9 L, and an efficiency of up to 97.5%. It enabled the test vehicle to complete the extreme challenge of a 60% slope, achieving stationary start on a half slope and in-place turning, significantly enhancing the vehicle's passage ability in complex terrains and improving its passability and maneuverability in special scenarios.

LanTu claims that this is the first axial flux motor in the field of passenger vehicles in China.

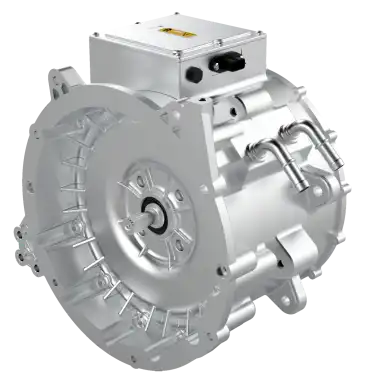

8 Xingqu Technology

Star Drive Technology showcased an axial flux motor at this exhibition. This is a motor product with extremely high torque density and a wide range of application scenarios. It can be used in EDU products, directly connected to an engine to become a range extender, or applied to the main shaft to be made into a drive motor for aircraft.

Summary

Axial flux motors have significant advantages. Their rotors are located on the side of the stator, and the large diameter design increases the torque density by more than 30% compared to traditional radial motors. Moreover, they consume less materials and have higher cost-effectiveness at the same power level. Additionally, they are compact and lightweight, which helps to enhance the driving range of electric vehicles and the utilization of space. The flat structure is convenient for integration and has excellent heat dissipation performance.

However, the magnetic pull between the stator and rotor of this motor is large. Although the "sandwich" structure can alleviate this issue, it increases structural complexity and cost. Moreover, as a new technology, its production process and quality control still need to be improved. Large-scale industrialization faces technical and cost pressures.

In addition, excessive power density will also pose new challenges for heat dissipation.

But the trend is unstoppable.