During the manufacturing process of ductile iron, there are a series of trace elements that interfere with the spheroidization process. Although the mass fraction of these elements in ductile iron is only a few parts per ten thousand or a few parts per hundred thousand, they can significantly affect the spheroidization effect. This interference is closely related to the magnesium content in the melt and the cooling rate, and the effects of various interfering elements are superimposed.

2025-05-20 16:07:38

Gears are commonly used components in mechanical design. By the cooperation of two gears, power can be transmitted. The combination of large and small gears can change the output speed and torque, while the cooperation of bevel gears can change the direction of power output. There are various forms of gear tooth profiles, among which involute tooth profile is the most common. The common processing methods of involute tooth profile are divided into two major categories: forming method and generating method. Here, we will not explain them in detail. Next, we will focus on introducing the common processing methods of gears.

2025-05-20 16:02:28

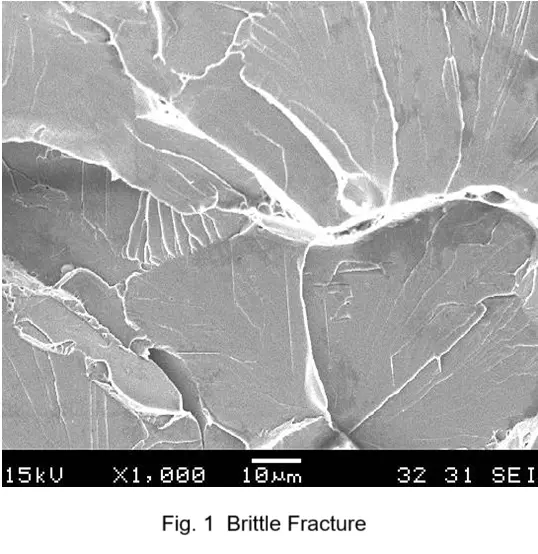

Fracture surface analysis holds a particularly important position in fracture failure analysis, as various information related to fracture is recorded on the fracture surface. Through the analysis of the fracture surface, the cause of fracture and its influencing factors can be identified. Microscopic fracture surface analysis mainly utilizes instruments such as metallographic microscopes, scanning electron microscopes (SEM), transmission electron microscopes (TEM), and electron probe microanalyzers (EPMA) to study the microscopic process of fracture, the fracture mechanism, and analyze various influencing factors leading to failure.

2025-05-19 12:06:23

_1747627357353.webp)

During the manufacturing process of ductile iron, there are a series of trace elements that interfere with the spheroidization process. Although the mass fraction of these elements in ductile iron is only a few parts per ten thousand or a few parts per hundred thousand, they can significantly affect the spheroidization effect. This interference is closely related to the magnesium content in the melt and the cooling rate, and the effects of various interfering elements are superimposed.

2025-05-19 12:03:15

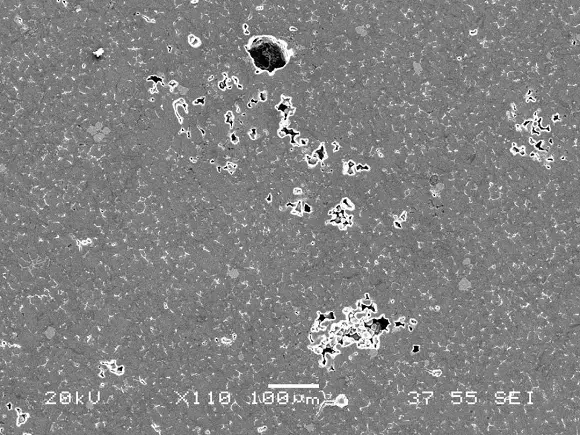

The discontinuity of metallic materials refers to the non-uniformity and sudden changes in their internal structure, composition or performance. In the study of failure analysis cases, it is found that many failures are caused by the discontinuity of materials.

The discontinuity of structure is mainly reflected in two aspects: internal defects and the inhomogeneity of the organization.

2025-05-19 12:01:51

During the manufacturing process of ductile iron, there are a series of trace elements that interfere with the spheroidization process. Although the mass fraction of these elements in ductile iron is only a few parts per ten thousand or a few parts per hundred thousand, they can significantly affect the spheroidization effect. This interference is closely related to the magnesium content in the melt and the cooling rate, and the effects of various interfering elements are superimposed.

2025-05-16 11:09:35

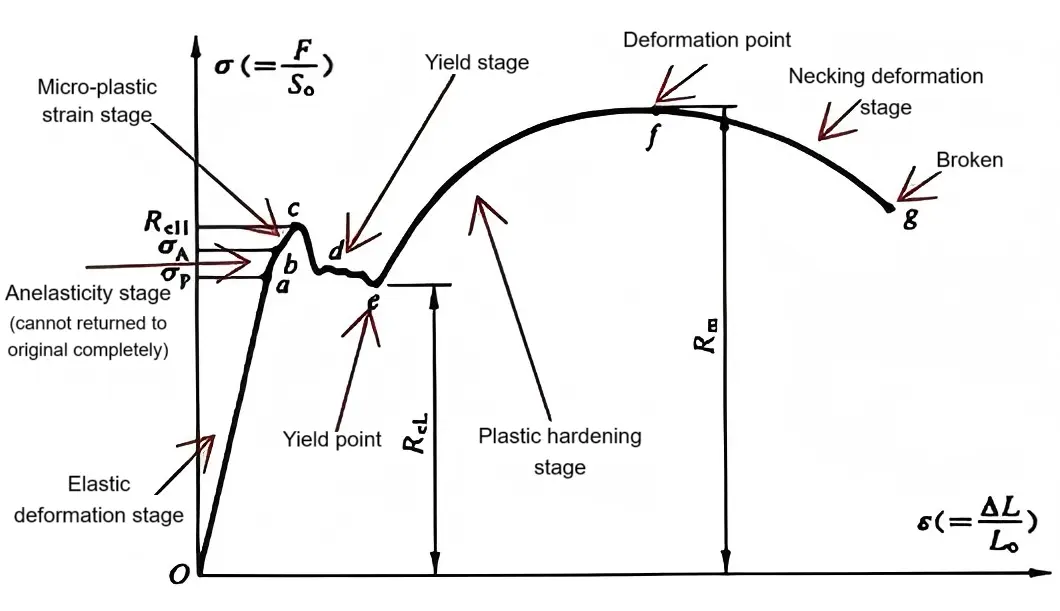

When the external force exceeds the elastic limit of the material, the material will undergo plastic deformation, that is, after unloading, the material retains some residual deformation. When the external force continues to increase to a certain value, the phenomenon occurs where the sample continues to elongate even though the external force does not increase or even decreases. This is manifested on the stress-strain curve as a plateau or sawtooth-shaped peaks and valleys, and this phenomenon is called the yield phenomenon. The force at the plateau stage is the yield force. The force before the first drop when the sample yields is called the upper yield force, and the minimum force during the yield stage without considering the instantaneous effect is called the lower yield force. The corresponding strengths are yield strength, upper yield strength, and lower yield strength.

2025-05-16 11:07:28

The traditional concept of purity of molten iron in cast iron focused on "reducing impurity content", but in the context of high-strength and high-toughness cast iron, this idea has become limited. Modern research shows that the essence of purity is "precise control of impurities" - certain elements or inclusions, in specific forms and distributions, can become "functional units" for performance optimization. This paper, based on the latest research, redefines the purity of molten iron and proposes control strategies for engineering implementation.

2025-05-14 17:53:42

_1747216148345.webp)

Molybdenum is a white malleable metal. Mo powder can be obtained by reducing the oxide of molybdenum with carbon, and then pressed into blocks, sintered and forged. The melting point of molybdenum is as high as 2620°C, which can reduce the tendency of steel to overheat. Molybdenum has high deformation resistance and, like nickel, can promote the distribution of sulfides in a pasty form on the grain boundaries. According to Goodrich's data, when the molybdenum content in molybdenum steel exceeds 1%, and according to Dumas' data, when it exceeds 3-4%, a brittle substance of fog-like (μ phase) molybdenum dioxide (MoO₂) will decompose at forging temperature. Molybdenum steel containing 0.7% C and 2-15% Mo has no special difficulty in hot working deformation. These steels can be quenched when cooled in air, and it is necessary to pay attention to prevent the formation of cracks during cooling.

2025-05-14 17:49:33

Abstract: In response to the issue of substandard impact energy absorption in 30CrNiMo cast steel parts after quenching and tempering, the reasons for the substandard impact energy absorption were analyzed through methods such as fracture analysis, metallographic examination, hardness testing, and chemical composition analysis. The results indicated that the fracture surface of the 30CrNiMo cast steel parts was intergranular. Metallographic examination revealed that the grains in the quenched state were uneven, with the presence of mixed grains. Nb accumulated at the original austenite grain boundaries to form NbC, which not only reduced the activity of the grain boundaries and hindered grain boundary migration but also formed numerous second-phase particles that pinned the grain boundaries and consolidated the grain boundary inheritance. Ultimately, this led to the coarsening of austenite grains, an increase in the ductile-brittle transition temperature of the steel, and the formation of brittle transgranular fractures and low impact performance when the steel was impacted at room temperature.

2025-05-14 17:47:13

The effect of nickel is opposite to that of manganese. Nickel can promote the distribution of sulfides in a pasty form along the grain boundaries. Therefore, in nickel steel, when the sulfur content increases, cracks will occur during forging or rolling. In high-nickel steel, heating in a furnace gas containing sulfur is most undesirable. The formed sulfides penetrate into the grain boundaries of the steel, causing surface cracks during forging or rolling.

2025-05-13 14:44:16

During the manufacturing process of ductile iron, there are a series of trace elements that interfere with the spheroidization process. Although the mass fraction of these elements in ductile iron is only a few parts per ten thousand or a few parts per hundred thousand, they can significantly affect the spheroidization effect. This interference is closely related to the magnesium content in the melt and the cooling rate, and the effects of various interfering elements are superimposed.

2025-05-13 14:40:02

367