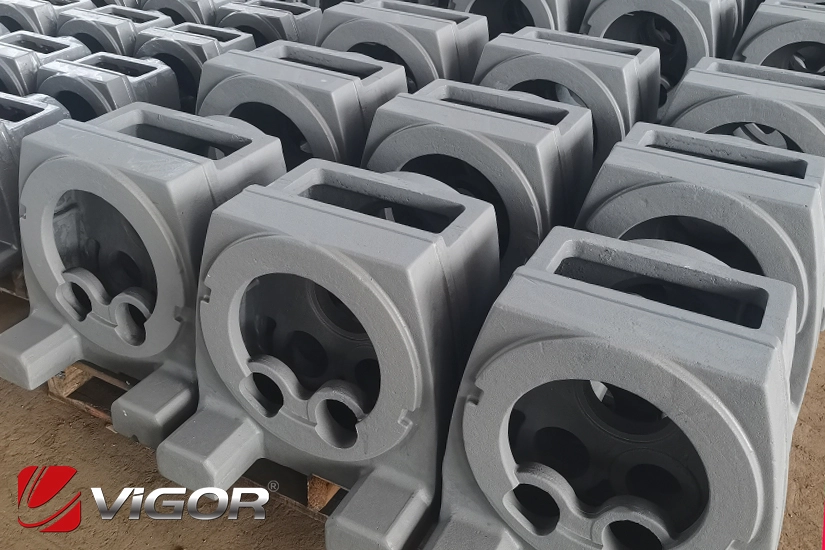

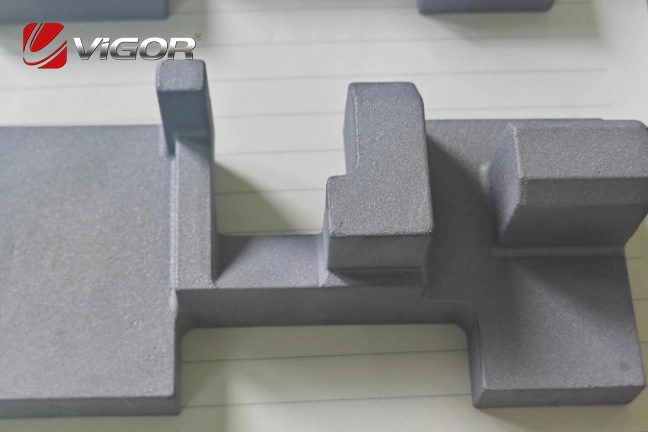

Cast iron has excellent casting properties, shock absorption, wear resistance, and machinability. It is relatively low-cost and widely used in general-purpose reducer housings. Its graphite is distributed in flake form, which weakens the continuity of the matrix, resulting in relatively lower strength and toughness. However, it can meet the requirements of most medium and low-speed reducers with small loads.

2025-06-11 16:28:39

Reducer gears play a crucial role in mechanical transmission and can be classified in various ways, each with its unique characteristics and application scenarios. Here is a detailed introduction to the different types of reducer gears and their features:

2025-06-11 16:17:26

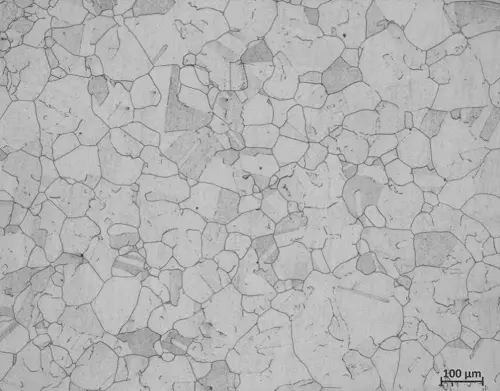

Taking 2Cr13 martensitic stainless steel as the research object, the effects of different nickel contents on the microstructure and comprehensive properties of 2Cr13 martensitic stainless steel were studied by means of metallographic microscopy, hardness testing and tensile testing at room temperature. The research results show that 2Cr13 martensitic stainless steel can obtain a fully martensitic structure after hot rolling in the single-phase austenite zone and air cooling. When w[Ni] is 0.1%, the martensite laths are relatively coarse. As w[Ni] increases to 0.3%, the hardness after heat treatment increases by 10HRC, and the yield strength, tensile strength and elongation after fracture increase from 614 MPa, 748 MPa and 30% to 670 MPa, 797 MPa and 33%, respectively. The mechanical properties of 2Cr13 martensitic stainless steel can be adjusted by increasing the tempering temperature and holding time to meet different order requirements.

2025-05-28 16:17:42

35CrMo and 40Cr, as common alloy structural steels, although widely used in mechanical manufacturing and engineering applications, each exhibit their unique characteristics and advantages in terms of chemical composition, mechanical properties, and specific application scenarios.

2025-05-28 16:14:45

During the manufacturing process of ductile iron, there are a series of trace elements that interfere with the spheroidization process. Although the mass fraction of these elements in ductile iron is only a few parts per ten thousand or a few parts per hundred thousand, they can significantly affect the spheroidization effect. This interference is closely related to the magnesium content in the melt and the cooling rate, and the effects of various interfering elements are superimposed.

2025-05-28 16:13:52

In the extreme working conditions of chemical engineering, nuclear power and other fields, Incoloy 800HT has become a star material in the pressure vessel industry due to its "high-temperature resistance, corrosion resistance and high strength" trinity performance. Today, we will deeply analyze the "genetic code" and practical capabilities of this alloy!

2025-05-27 17:01:19

Recrystallization refers to the crystallization process of solid metals and alloys without phase transformation. It is the process of softening metals or alloys that have undergone work hardening without phase transformation.

2025-05-27 16:43:18

During the solution treatment of 17-4PH martensitic stainless steel, elements such as copper and niobium dissolve into the austenite grains. After cooling, supersaturated copper and niobium martensite is obtained, achieving the first strengthening. Then, during the aging process, the supersaturated copper and niobium elements in the grains precipitate, which provides the second strengthening for the matrix. This is the main strengthening method for 17-4PH steel.

2025-05-27 16:29:34

17-4PH stainless steel (ASTM) is a martensitic precipitation-hardening stainless steel, equivalent to the national standard 05Cr17Ni4Cu4Nb. This type of stainless steel has a low carbon content, high Ni and Cr content, good weldability and excellent corrosion resistance. At the same time, the content of alloying elements such as Cu and Nb in this steel is also relatively high. These alloying elements can precipitate and age hardening phases such as ε-Cu, NbC, and M23C6 during heat treatment, endowing the material with high strength and hardness. Due to these advantages, 17-4PH martensitic precipitation-hardening stainless steel is widely used in aerospace, chemical, and nuclear industries, among others. The mechanical properties of precipitation-hardening stainless steel are significantly related to the heat treatment state. The conventional heat treatment process for 17-4PH martensitic precipitation-hardening stainless steel is solution treatment + aging treatment, which improves strength, hardness, and corrosion resistance by adjusting the microstructure and controlling the precipitated phases. Currently, the research on the heat treatment process of 17-4PH stainless steel is quite mature. This article summarizes and briefly describes its performance and mechanism under different heat treatment processes.

2025-05-21 16:48:32

After quenching and tempering treatment, 40Cr steel has excellent comprehensive mechanical properties, is moderately priced, and is easy to process. Currently, it is one of the most widely used steel grades in the machinery manufacturing industry. China Vigor is actively and deeply involved in the deep processing sites of its customers to understand their product process flows; by analyzing abnormal samples, it identifies the fundamental causes of surface cracks in 40Cr forgings and proposes solutions. On the one hand, it guides customers to improve their production processes and maintains a good relationship with them; on the other hand, it also understands the terminal uses of the products and promptly adjusts the production processes of 40Cr continuous casting billets (or rolled materials) to produce products that meet market demands.

2025-05-21 16:44:39

During the manufacturing process of ductile iron, there are a series of trace elements that interfere with the spheroidization process. Although the mass fraction of these elements in ductile iron is only a few parts per ten thousand or a few parts per hundred thousand, they can significantly affect the spheroidization effect. This interference is closely related to the magnesium content in the melt and the cooling rate, and the effects of various interfering elements are superimposed.

2025-05-21 16:25:53

Austenitic stainless steel has a main body of austenitic structure (γ phase) with a face-centered cubic (fcc) lattice. Common types include 304, 316, etc. It is non-magnetic and is mainly strengthened through cold working.

2025-05-20 16:14:38

367