Knowledge

The Molten Metal Solidification of Casting

The solidification principle, sequence and characteristics of the molten metal during casting are as follows:

Solidification principle: Casting is an important metal forming process, and its core principle lies in the utilization of the property of metals melting into liquid at high temperatures and solidifying back into solid state during the cooling process. Specifically, in the casting process, the raw materials of metals or alloys are first heated above their melting points to completely melt into liquid metals with certain chemical compositions and appropriate temperatures. Then, under the drive of gravity or external pressure, the liquid metal is smoothly poured into the pre-prepared mold cavity. As the temperature gradually decreases, the liquid metal begins to solidify and eventually forms a casting of the desired shape and size within the mold cavity. This process not only involves the physical state change of metals but also accompanies complex chemical and metallurgical reactions.

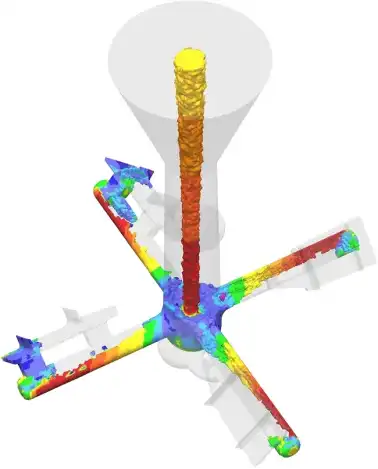

Solidification sequence: The solidification sequence of molten metal directly affects the microstructure and properties of castings, mainly divided into three types: sequential solidification, simultaneous solidification and intermediate solidification.

During sequential solidification, the ingot solidifies gradually from the edge to the center, which is conducive to the formation of well-arranged columnar crystals. The characteristic of this solidification mode is that the solidification zone is relatively narrow, and the growth direction of columnar crystals is consistent with the direction of heat flow, resulting in the formation of concentrated shrinkage cavities inside the ingot. Although concentrated shrinkage cavities are convenient for subsequent processing, they may also affect the mechanical properties of the casting.

Meanwhile, under the solidification mode, all parts of the ingot start to solidify almost simultaneously. The grains in the liquid metal can grow freely, forming coarse equiaxed dendrites. When these coarse dendrites connect with each other, they enclose the remaining liquid metal, eventually resulting in dispersed shrinkage cavities. These dispersed shrinkage cavities are distributed relatively uniformly, but they may increase the porosity of the casting.

Intermediate solidification lies between sequential solidification and simultaneous solidification. In the ingot, there are both columnar crystal regions and equiaxed crystal regions. This solidification mode strikes a balance to some extent between the advantages and disadvantages of the two crystal types, but it is more difficult to control and requires precise process parameters and strict operating procedures.

Solidification characteristics: The solidification characteristics of molten metal are influenced by multiple factors, including the quality of the metal charge, metallurgical reactions during melting, the properties of the molding material and the performance of the mold, the interaction between the mold and the liquid metal, the pouring scheme and its process parameters (such as pouring temperature and pouring speed), as well as the solidification rate, direction and mode determined by the temperature field. These factors interweave and jointly determine the final quality and performance of the casting.

The quality of the metal charge directly affects the purity and compositional uniformity of the liquid metal, while metallurgical reactions during melting determine the chemical properties and microstructure of the liquid metal. The properties of the molding material and the performance of the mold affect the fluidity of the liquid metal and heat conduction during the solidification process. The interaction between the mold and the liquid metal, such as wettability and interfacial reactions, also has a significant impact on the solidification process.

The selection of the pouring scheme and its process parameters is particularly crucial. If the pouring temperature is too high or too low, or the pouring speed is too fast or too slow, it may lead to macroscopic defects such as shrinkage cavities, porosity, gas holes, slag inclusions and impurities, as well as cracks in the casting. These defects not only affect the appearance and dimensional accuracy of the casting, but may also significantly reduce its mechanical properties and service life.

In addition, the solidification rate of castings is also restricted by the thermal physical properties of the metal and the mold. Regarding the metal, metals with a high melting point, low density and low latent heat solidify relatively faster, while those with the opposite properties solidify more slowly. As for the mold, the greater the heat storage coefficient of the mold, that is, the higher the thermal conductivity and specific heat capacity of the mold material, the faster the solidification rate of the casting. These differences in thermal physical properties need to be fully considered in the design and operation of the casting process to ensure that the quality and performance of the casting meet the expected requirements.

Vigor is the expert on castings, if you have any question, demand, parts development or improve your supply chain, please feel free to contact us at info@castings-forging.com