Knowledge

(Heat treatment) Detailed Analysis of the Heating Process and Internal Structural Changes of Steel

I. The Basic Principles of Organizational Transformation

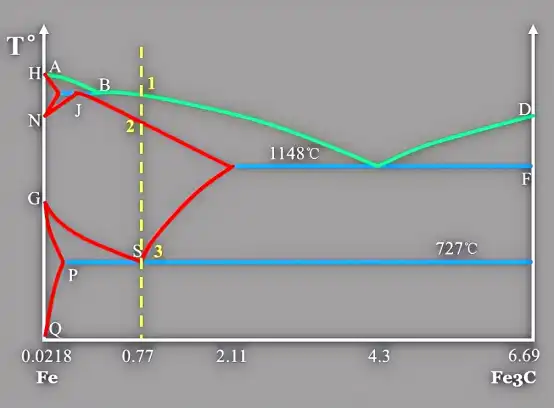

During the heating process of steel, the transformation of microstructure is a process where one crystal phase is transformed into another. Taking hypereutectoid steel as an example:

- Eutectoid steel: The carbon content is approximately 0.77%, and at room temperature, it mainly exists in the form of pearlite (a layered structure composed of ferrite and cementite).

- Austenite: Face-centered cubic (FCC) structure, capable of dissolving more carbon, and it is the stable phase at high temperatures.

According to the iron-carbon phase diagram, theoretically speaking, when steel is heated to 723 degrees Celsius, pearlite will transform into austenite. However, in reality, due to the heating speed and the duration of the transformation process, the actual transformation temperature is higher than 723 degrees Celsius, which is known as thermal hysteresis. We mark this actual transformation temperature as Ac1. The faster the heating speed, the higher Ac1 is, and the shorter the transformation time is. (Because there is a minimum transformation time for the transition from pearlite to austenite, it cannot be completed instantly like the transformation from austenite to martensite. Therefore, the transformation from pearlite to austenite will have a minimum time. Within this time, the significance of increasing Ac1 is not significant. However, there is an exception to this rule. That is the inversion of martensite. That is, martensite directly transforms into austenite. The transformation time in this case will also be very short.)

II. Transformation Process from Pearlite to Austenite

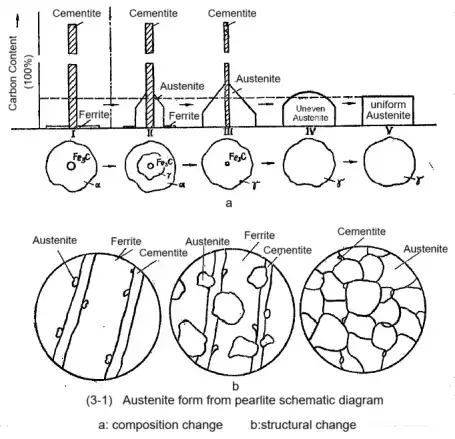

This process can be divided into three main steps:

1. Nucleation

- Temperature condition: The temperature exceeds 723℃, reaching or exceeding Ac1.

- Structural change: Austenite nuclei begin to form within the pearlite.

- Mechanism: The crystal lattice structure of iron changes from body-centered cubic (BCC) to face-centered cubic (FCC), and at the same time, the carbon in ferrite and cementite redistributes, initially forming austenite nuclei.

2. Nucleus growth

- Process: The austenite nucleus begins to grow and spreads throughout the pearlite.

- Expansion mechanism: Ferrite continuously transforms into austenite, and carbon in the cementite diffuses into the austenite and gradually dissolves.

- Temperature and time: This process will continue until the entire pearlite is completely transformed into austenite. The higher the temperature, the faster the transformation, but excessively high temperatures will cause grain coarsening.

3. Homogenization of Components

- Objective: To homogenize the carbon content within austenite.

- Holding Time Function: After the transformation from pearlite to austenite is completed, a certain period of holding time is required to allow carbon to diffuse fully within austenite, achieving homogenization.

- Impact of Excessive Holding Time: Excessive holding time will cause the austenite grains to further grow, resulting in a coarse grain structure, thereby reducing the mechanical properties of the material.

III. Grain Size and Its Control

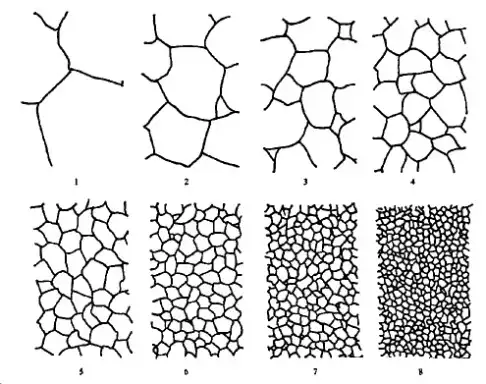

Grain size is an important factor influencing the mechanical properties of steel. The finer the grains, the higher the strength and toughness of the material. Different steel grades have different sensitivities to overheating:

- Essentially coarse-grained steel: highly sensitive to over-heating; when the temperature is slightly higher, the grains grow rapidly.

- Essential fine-grained steel: It is not sensitive to over-heating and can maintain fine grains at higher temperatures.

The size and quantity of grains vary with the duration of holding and the temperature. When we talked about martensite earlier, we also mentioned that the finer and more numerous the grains are, the more complex the grain boundaries are, and the greater the corresponding strength will be. Conversely, the strength will be relatively lower. Therefore, the control of grain size is particularly important. However, in actual production, different steel grades react differently to temperature. Some steels are very sensitive to over-heating and the grains will significantly grow when the temperature is slightly higher. While for some other steels, the grain size does not change significantly within a certain range of over-heating. In production, the former is called essential coarse-grained steel and the latter is called essential fine-grained steel. The following figure expresses the tendency relationship between essential coarse-grained and essential fine-grained steels.

In actual production, the heating temperature and holding time need to be controlled according to the specific steel type and process requirements to achieve the best grain size. First of all, the so-called "essentially coarse grains" and "essentially fine grains" are only in terms of their sensitivity to over-heating and do not represent the actual comparison of their final grain sizes. If the temperature is controlled properly, essentially coarse grains can also achieve very fine grain sizes, and vice versa, essentially fine grains can also be very coarse. For example, for 20Cr, when heated normally (not higher than 930°C), the grain size of 20Cr is very fine. However, when carburizing treatment is required, since the heating temperature often needs to be higher than 930°C, the actual grain size may become coarser. Secondly, here we will not delve into which steel is essentially coarse and which is essentially fine. Because as a classification, it does not have much guiding significance for practical applications.

Our country has set different grades of 1-8 for grain size evaluation. The following figure shows the schematic diagram of the standard grain size grades of steel.

IV. Defects and Prevention during Heating Process

1. Overheating

- Manifestation: Austenite grain coarsening, deterioration of material properties.

- Prevention: Control heating temperature and duration. If necessary, re-refining the grains through normalizing or annealing treatment.

2. Overburning

- Manifestation: Oxidation of austenite grain boundaries and even local melting occur, resulting in material brittleness and irreparable damage.

- Prevention and Control: Strictly control the heating temperature to avoid reaching the overburning temperature.

3. Oxidation

- Manifestation: Oxidation occurs on the surface of steel, forming an oxide layer, which affects the dimensional accuracy and surface quality. For oxidation below 560 degrees Celsius, since it mainly consists of ferrous trioxide, the surface is dense and can effectively prevent further oxidation. However, when the temperature exceeds 560 degrees Celsius (which is the heating temperature for most steel heat treatments), a loose FeO layer is formed, which cannot prevent further oxidation. Therefore, the longer the time, the more severe the dimensional changes and roughness caused by oxidation will be. Therefore, in practice, protective measures should be adopted to avoid oxidation.

- Prevention and Control: Use protective atmospheres during heating or apply anti-oxidation coatings.

4. Decarburization

- Manifestation: The surface carbon is oxidized to form a decarburization layer, which reduces the hardness and wear resistance of the surface.

- Prevention and Control: Use a protective atmosphere or coating to minimize the contact with oxygen and other oxidizing gases.

V. Optimization of Heating Process

In order to optimize the heating process, the following factors need to be comprehensively considered:

1. Material properties: Based on the state diagrams of different steel grades, determine the appropriate heating temperature and holding time.

2. Part dimensions and shapes: Take into account the differences in dimensions and cross-sections of the parts, and adjust the heating speed and holding time to avoid deformation and cracking.

3. Protective measures: Use protective atmospheres, coatings or other measures to prevent oxidation and decarburization.

Through reasonable control of the heating process, while ensuring uniform transformation of the microstructure, defects such as overheating, overburning, oxidation and decarburization can be avoided, thereby obtaining excellent mechanical properties.

If you have any questions and demand on heat treatment, or parts development, improve your supply chain, please feel free to contact us at info@castings-forging.com