Knowledge

The Method to Improve the Strength and Toughness of Metal Materials

Strength refers to the ability of a metallic material to resist plastic deformation and fracture under the action of external force. For example, tensile strength, compressive strength, flexural strength, and shear strength are all types of strength.

Ductility refers to the ability of a metallic material to absorb the energy of plastic deformation before fracture. It measures the amount of energy required for a material with cracks to undergo fracture. Impact toughness and fracture toughness are examples of ductility. The more ductile a material is, the more energy is required to cause crack propagation to fracture.

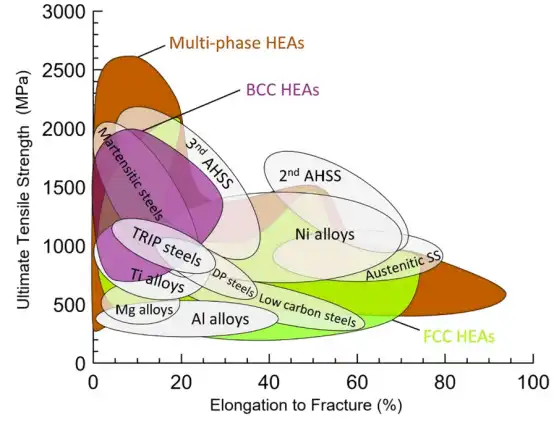

Fig. 1 Ultimate tensile strength vs. ductility map of HEAs relative to conventional alloys. SS, AHSS, and TRIP represent stainless steels, advanced high-strength steels, and transformation-induced plasticity, respectively (Progress in Materials Science 136 (2023) 101106)

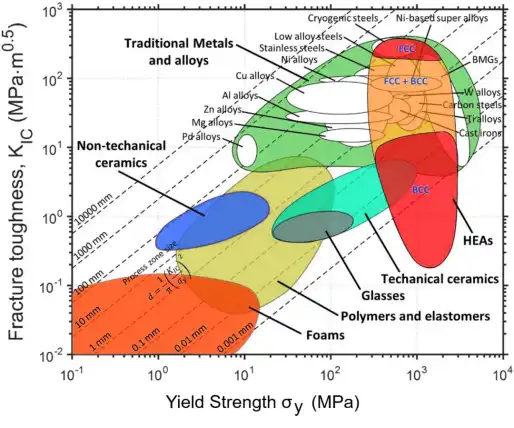

Fig. 2. Ashby plot of fracture toughness vs. yield strength of HEAs in context with conventional alloys/metals. The dotted lines reflect the size of the process zone at the crack tip (Progress in Materials Science 136 (2023) 101106)

Methods to enhance the strength of metal materials:

Solid solution strengthening: Alloying elements are dissolved into the matrix metal to cause a certain degree of lattice distortion, thereby increasing the strength of the alloy. The influencing factors include the atomic fraction of the solute atoms, the difference in atomic size, the type (interstitial solute atoms are more effective than substitutional atoms), and the difference in valence electrons between the solute atoms and the matrix metal.

Work hardening (deformation strengthening): With the increase in cold deformation degree, the strength and hardness of the metal material increase, but the plasticity and toughness decrease. The principle is that dislocations intersect, react, proliferate, etc., increasing the resistance to dislocation movement. Cold deformation methods such as cold pressing, rolling, and shot peening can be adopted.

Fine grain strengthening: The mechanical properties of the metal material are improved by refining the grain size. The principle is that fine grains, when deformed under external force, can be dispersed in more grains, resulting in more uniform plastic deformation, less stress concentration, and larger grain boundaries, which are unfavorable for crack propagation. Methods include increasing the undercooling degree, normalizing treatment, vibration, and stirring, and controlling the deformation degree and annealing temperature of the cold-deformed metal. Alloy elements can also be added to steel to inhibit grain growth.

Second phase strengthening: When second phases are uniformly distributed as fine and dispersed particles in the matrix phase, they produce significant strengthening effects. It is divided into the strengthening effect of non-deformable particles (overturning mechanism) and the strengthening effect of deformable particles (cutting mechanism). Diffusion strengthening and precipitation strengthening are special cases of second-phase strengthening.

Phase transformation strengthening: Through certain processes, the phases or structures of the metal material undergo transformation to produce strengthening effects. It combines the strengthening effects of solid solution strengthening, precipitation strengthening, and fine-grain strengthening. For example, in steel, the martensite formed during quenching is an oversaturated solid solution, with a strong solid solution strengthening effect, and the dislocation density in martensite is high, with a dislocation strengthening effect. Its bundle orientation is different and fine, with a fine-grain strengthening effect. After quenching martensite is reheated, and a large number of fine and dispersed carbides can be precipitated, generating second-phase strengthening.

Grain boundary strengthening: Adding trace amounts of surface-active elements, such as boron and rare earth elements, to steel, causing internal adsorption to concentrate at the grain boundaries, can significantly improve the creep limit and ultimate strength of the steel. The essence of grain boundary strengthening is the hindering effect of the grain boundary on the movement of dislocations. The smaller the grain size and the more grain boundaries, the greater the hindering effect, and the better the strengthening effect. At the same time, it can also improve the toughness of the steel.

Methods to enhance the toughness of metal materials:

Composition and structure design:

Alloying: Adding different elements or compounds to adjust the composition and structure of the material, such as adding alloy elements like C, Mn, Ni, Cr, Mo, V, etc. in steel.

Controlling grain size: Generally, the smaller the grain size, the higher the toughness.

Interface design: Reasonably designing the interfaces in the microstructure of the metal material, such as surface treatment and adding composite phases.

Processing and heat treatment:

Cold deformation processing: Changing the microstructure and grain size of the metal material to improve toughness and plasticity.

Heat treatment: Including annealing, normalizing, quenching, etc. For steel, normalizing treatment can increase its strength and toughness, and reduce brittleness; preparing nano-crystalline metal materials, due to their small size and high interface density, exhibit excellent mechanical properties and excellent toughness.

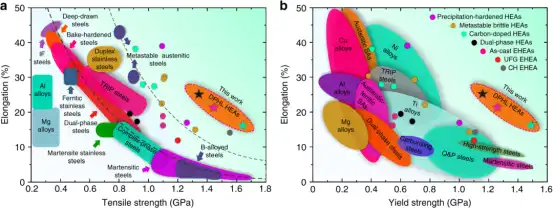

Fig. 3. Comparison of (a) elongation vs. tensile strength and (b) elongation vs. yield strength of HEAs in context with other conventional materials[. DPHL-dual-phase heterogeneous lamella.

Methods for simultaneously enhancing strength and toughness:

By comprehensively applying the aforementioned strengthening mechanisms and methods, such as optimizing the microstructure and properties through controlling the composition and processing techniques of the materials, for instance, controlling the content of alloying elements and selecting appropriate heat treatment processes; adopting the design of composite materials or multiphase materials to achieve the combination of strength and toughness; utilizing surface treatment or coating technologies to enhance the surface strength and toughness of the materials. Specific methods can be selected based on actual needs and material characteristics. At the same time, it should be noted that strength and toughness often have certain contradictions. While enhancing strength, efforts should be made to avoid excessive reduction of toughness. Moreover, different strengthening methods may have different effects on different strength indicators, and specific situations require selection and adjustment.

If you have any questions, demand, parts development, or improve your supply chain, please feel free to contact us at info@castings-forging.com