Knowledge

What is gravity die casting?

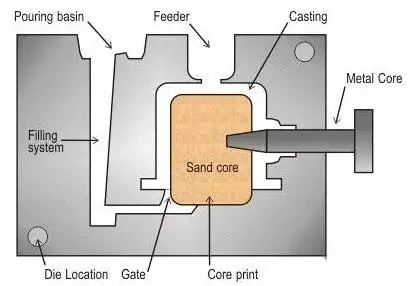

gravity die casting is a modern process of producing castings using molds made of metal materials (such as heat-resistant alloy steel, ductile iron, heat-resistant cast iron, etc.). This casting method is suitable for gravity casting and pressure casting, and can be used repeatedly, with high production efficiency and casting quality.

Casting quality: The casting structure of metal casting is dense, and the mechanical properties are about 15% higher than that of sand casting

Dimensional accuracy and surface roughness: Metal castings have high dimensional accuracy and low surface roughness value, and good quality stability

Production efficiency: Metal type can be used many times, pouring times can reach tens of thousands of times without damage, saving working hours and modeling materials, improve productivity

Environment and working conditions: Because of the lack of or less use of sand core, gravity die casting improves the environment, reduces dust and harmful gases, and reduces labor intensity

Design and manufacturing costs: Metal type design, manufacturing, use and maintenance requirements are high, production preparation time is long, and mold costs are relatively high

Permeability and conciliation: the metal type itself has no permeability and conciliation, and the casting is prone to cracks and deformation during solidification

Applicability: Metal casting is mainly suitable for mass production of non-ferrous metal castings and gray cast iron with simple shape, such as internal combustion engine piston, cylinder block, bearing bush, bushing and so on

Metal utilization rate: The metal utilization rate of metal casting is relatively low, the casting of thin-walled complex castings is difficult, and the tissue density of castings is low relative to pressure casting

Although metal casting is high in manufacturing cost, it usually shows good economic results in mass production due to the high quality and production efficiency of its castings. This process is especially suitable for the production of small and medium castings of non-ferrous metals, as long as the melting point of the casting material is not high, metal casting is often the preferred method.

Welcome to contact Vigor for more detailed information, call us at 029 81161513 or email us at info@castings-forging.com