Knowledge

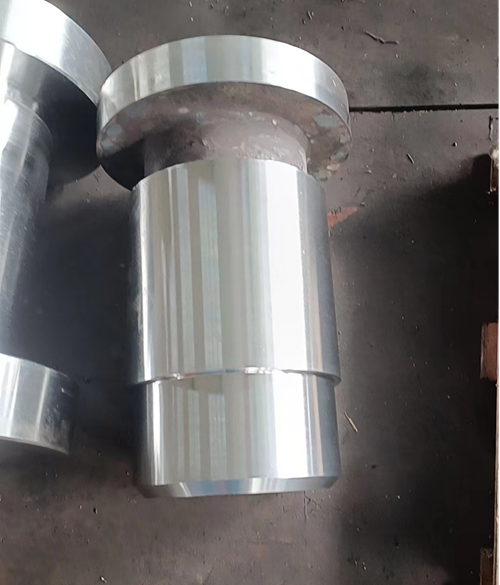

UNS NO6600 Nickel-based Alloy Forgings

UNS NO6600 alloy is a Ni-Cr alloy that can be used in a temperature range from cryogenic to 1093℃. UNS NO6600 alloy is non-magnetic and has good weldability. UNS NO6600 alloy can be used in a wide range of corrosive environments. The high nickel content gives 600 alloy certain corrosion resistance in reducing environments, while the addition of chromium gives 600 alloy certain corrosion resistance in weakly oxidizing environments. Due to its relatively high nickel content, 600 alloy has excellent corrosion resistance to chloride stress corrosion cracking. The formability of 600 alloy is similar to that of stable austenitic stainless steel.

Alloy 600 is resistant to various corrosive media. The chromium content makes this alloy more corrosion-resistant than nickel 99.2 (Alloy 200) and nickel 99.2 (Alloy 201, low carbon) under oxidizing conditions. Meanwhile, the higher nickel content gives the alloy excellent corrosion resistance in reducing conditions and alkaline solutions, and effectively prevents chloride-iron stress corrosion cracking. Alloy 600 has excellent corrosion resistance in organic acids such as acetic acid, formic acid, and stearic acid, and moderate corrosion resistance in inorganic acids. It also has outstanding corrosion resistance in high-purity water used in the primary and secondary circuits of nuclear reactors.

The particularly outstanding performance of 600 is its resistance to dry chlorine gas and hydrogen chloride corrosion, with an application temperature up to 650℃. At high temperatures, both the annealed and solution-treated alloys exhibit excellent oxidation and spalling resistance and high strength in air. The alloy is also resistant to ammonia and nitriding and carburizing atmospheres, but under alternating oxidative and reductive conditions, it is subject to partial oxidation by certain media (such as green death solution).

Chemical composition of UNS NO6600

1. Nickel (Ni): Approximately 72% (maximum content)

Nickel is the main component of the alloy, providing it with a high nickel content to enhance corrosion resistance and high-temperature performance.

2. Chromium (Cr): 14.0 - 17.0%

Chromium significantly improves the alloy's oxidation resistance and high-temperature strength.

3. Iron (Fe): ≤ 6.0%

Iron serves as the base element and, together with nickel and chromium, forms a solid solution.

4. Carbon (C): ≤ 0.15%

Carbon content is strictly controlled to minimize the risk of brittleness.

5. Manganese (Mn): ≤ 1.0%

Manganese, as an alloying element, assists in strengthening and grain refinement.

6. Silicon (Si): ≤ 0.5%

Silicon content is low and is mainly used for deoxidation and fine-tuning alloy properties.

7. Other elements:

Contains trace amounts of aluminum (Al), titanium (Ti), etc., which may be used for grain refinement or improved corrosion resistance.

Application fields of UNS NO660

1. Thermocouple sheaths in corrosive atmospheres

2. Vinyl chloride monomer production: Resistance to chlorine gas, hydrogen chloride, oxidation and carbonization corrosion

3. Uranium oxide conversion to hexafluoride: Resistance to hydrogen fluoride corrosion

4. Production and use areas of corrosive alkali metals, especially in environments with sulfides

5. Titanium dioxide production by chlorine process

6. Production of organic or inorganic chlorides and fluorides:

7. Nuclear reactors

8. Swan-neck bottles and components in heat treatment furnaces, especially in carbonization and nitridation atmospheres

9. Alloy 600 is recommended for catalytic regenerators in petrochemical production at temperatures above 700°C to achieve a longer service life.

In engineering practice, 600 is often used, which is a nickel-based solid solution strengthening high-temperature alloy. There are many difficulties in the cutting processing of this material, such as large cutting force, high cutting temperature, and severe tool wear. In response to these difficulties, this paper proposes reasonable choices of cutting parameters, tool materials, tool geometry angles, and cutting fluids when processing this material.

Vigor has more than 20 years experience and the professional team in castings and forging as well as the post of treatment processes. If you have any question or products need to do, please feel free to contact us at info@castings-forging.com