Knowledge

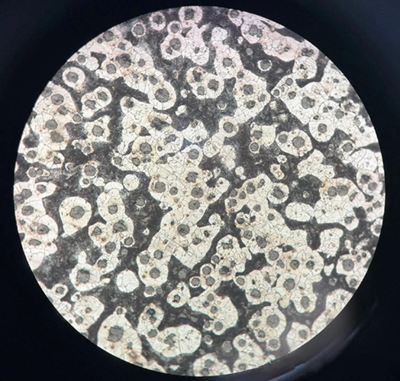

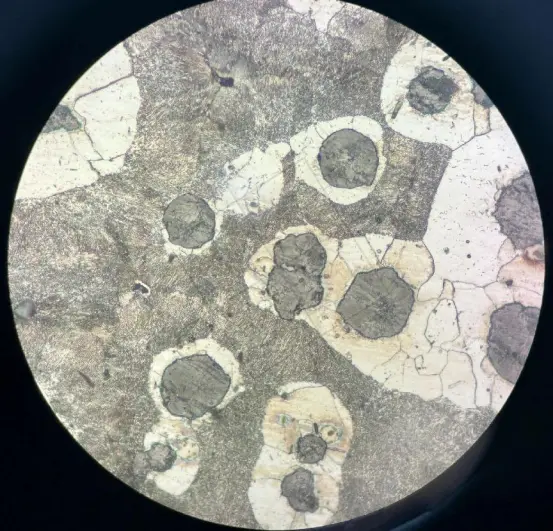

The Typical Micro-Structure of Ductile Iron

The illustration shows the typical microstructure morphology of ductile iron. The black dots in the picture represent the "spherical graphite" of the lamellar structure; the black patches represent "pearlite"; the bright and uniform structure formed around the carbon-poor areas of the spherical graphite in the picture is "ferrite".

The formation mechanism of ductile iron: Before pouring the molten iron alloy into the mold, a proper proportion of balling agents (such as magnesium, rare earth, etc.) and nucleating agents (such as silicon iron, silicon calcium alloy, etc.) are placed at the bottom of the steel mold to make the carbon in the alloy liquid attach to the core of the balling agents in a radial spherical growth form, and be controlled by the nucleating agents to control the growth of graphite spheres. According to the mechanical performance requirements, different sizes and particle numbers of graphite are obtained to achieve different grades of ductile iron.

Microscopic observation method: Zeiss observer 7m

Vigor team has more than 20 years experience in casting, forging, cold forming processes and the post treatment, as well as a robust surface treatment supply chain. If anything we can help or any parts you want to develop, please contact us at info@castings-forging.com