Knowledge

The Dispersion Strengthening Mechanism of Metal Materials and Its Applications

The strengthening of metals includes solid solution strengthening, strain strengthening and dispersion strengthening. The following is an introduction to dispersion strengthening.

I. Diffusion Strengthening Mechanism

The core idea of dispersion strengthening is to introduce uniformly distributed, high-hardness and high-stability fine second-phase particles to impede the movement of dislocations within the metal crystal, thereby enhancing the material's strength and hardness.

To better understand it, we can break it down into the following key points:

Basic principle: Obstruct dislocation movement

· Dislocations: The plastic deformation of metals (i.e., permanent deformation) is mainly achieved through the movement of linear defects within the crystal called "dislocations". It can be imagined as a crease in a carpet; pushing this crease to move is much less effort than dragging the entire carpet.

· Nature of Strengthening: The strength of a material directly depends on the force required to start the movement of dislocations. Any obstacle that hinders the movement of dislocations can enhance the strength of the material.

2. Key Role: Dispersed Phase Particles

These introduced particles are called "dispersed phase", and they usually have the following characteristics:

· High hardness and high melting point: They are not prone to deformation or dissolution by themselves, such as oxides (Al₂O₃, ThO₂), carbides, nitrides, etc.

· Chemical inertness: They do not undergo chemical reactions with the metal matrix and remain stable even at high temperatures.

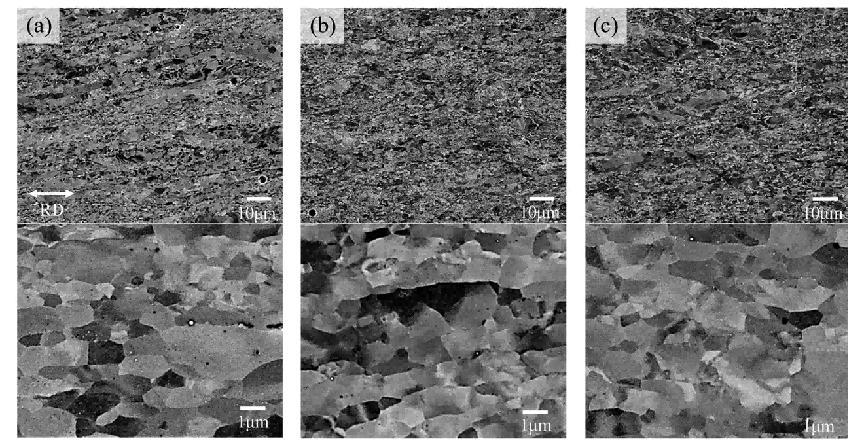

· Fine and uniform: The particle size is typically in the range of 0.01 to 0.1 micrometers and is evenly distributed in the matrix.

3. Core Mechanism: Orowan Bypass Mechanism

It is the most classic and important theoretical model for explaining dispersion strengthening. Just like a rope passing through a meadow full of sturdy stumps. The rope must bend around each stump, and this process requires additional force. Each time a stump is bypassed, a "loop" is left around it. Subsequent dislocation lines will encounter more and more of these loops, making it increasingly difficult to bypass the particles, thereby achieving continuous strengthening.

The shear stress required for dislocation line bending (i.e., the strengthening effect) is inversely proportional to the spacing of the particles: the finer and more densely distributed the particles (the smaller the spacing λ), the more significant the strengthening effect.

4. The Difference from Precipitation Hardening

Although the mechanisms are similar, dispersion strengthening is fundamentally different from the common precipitation strengthening:

· Particle properties: The particles in dispersion strengthening are foreign additions, inert, and extremely stable at high temperatures; while the particles in precipitation strengthening are internally precipitated from the supersaturated matrix, have a coherent relationship with the matrix, but will coarsen or dissolve at high temperatures, leading to a decrease in strength.

· Temperature stability: The high-temperature performance of dispersion-strengthened materials is far superior to that of precipitation-strengthened materials.

II. Important Roles

The role of dispersion strengthening is far more than just enhancing the strength and hardness at room temperature. Its more significant meaning lies in extreme environments:

Significantly improve high-temperature strength (creep resistance)

This is the most important function of dispersion strengthening. At high temperatures, the metal matrix may soften, but the high-melting-point and stable dispersed particles remain firm. They can continuously and effectively pin dislocations and grain boundaries, preventing the material from undergoing slow plastic deformation (i.e., creep) under stress and high temperatures. This makes dispersion-strengthened materials key materials for manufacturing aircraft engine blades, rocket engine components, and high-temperature nuclear power components.

2. Increase the recrystallization temperature

Metals that have undergone cold working will undergo recrystallization and grain growth at high temperatures, leading to softening. Dispersed particles can effectively pin grain boundaries, significantly hindering the recrystallization process and grain growth, enabling the material to maintain a work-hardened state and fine-grained structure at higher temperatures.

Maintain a relatively high room temperature strength and hardness.

Through the Orowan mechanism, dispersed particles can provide significant strengthening effects at room temperature.

4. While strengthening, it causes less damage to plasticity and toughness.

Compared with severe work hardening (which can significantly reduce plasticity), dispersion strengthening usually retains better plasticity. This is because dislocations can continue to move through a "bypass" mechanism rather than being completely locked. Compared with coarse and uneven inclusions, fine and uniform dispersions have a less adverse effect on toughness.

Application Examples

The most famous dispersion-strengthened materials are SAP (sintered aluminum powder) and TD-Ni (ThO₂ dispersion-strengthened nickel-based alloy).

· SAP: It is produced by generating an aluminum oxide film on the surface of aluminum powder and then compacting and sintering it through powder metallurgy. The Al₂O₃ particles within it significantly enhance the high-temperature strength and recrystallization temperature of aluminum.

· ODS (Oxide Dispersion Strengthened) alloys: An important branch of modern high-temperature alloys, they are made by uniformly dispersing oxides such as Y₂O₃ in nickel-based or iron-based alloys through techniques like mechanical alloying, and are used to manufacture the most advanced gas turbine blades.

The essence of dispersion strengthening lies in using stable, fine and evenly distributed hard particles as obstacles to hinder dislocation movement through the Orowan bypass mechanism, thereby enhancing the material's strength. Its most crucial and irreplaceable role is that it significantly improves the creep resistance and strength of metallic materials at high temperatures, making it an indispensable key material technology in high-end technological fields such as aerospace and energy power.

Vigor team has more than 20 years experience in casting, forging, cold forming processes and the post treatment, as well as a robust surface treatment supply chain. If anything we can help or any parts you want to develop, please contact us at info@castings-forging.om