Knowledge

Some Basic Parameters of Shot Blasting Intensity

There are many basic parameters for shot blasting. The common ones include shot blasting intensity (the requirements for shot blasting and shot peening in parameter control are the same, so shot peening is used to represent both shot blasting and shot peening in the following text), shot blasting coverage, surface roughness of the workpiece, and surface cleanliness of the workpiece.

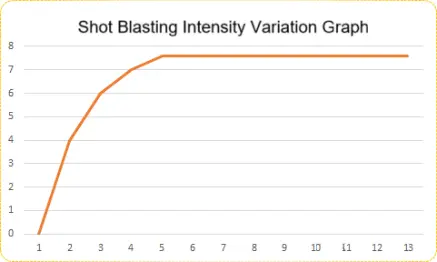

Shot peening intensity is a topic that encompasses a wide range of content and has many research aspects. However, as a popular science article for application purposes, let's try to explain it as simply as possible. Shot peening intensity can be simply understood as the ability of a "shot peening flow" to introduce a residual compressive stress layer depth. The main process parameters that affect shot peening intensity include: shot diameter, shot flow velocity, shot flow rate, and shot peening time. Correspondingly, the larger the shot diameter, the faster the speed, and the greater the momentum of the shot peening flow when it collides with the workpiece (corresponding to the distance from the workpiece), the greater the shot peening intensity. Of course, there is a peak value for shot peening intensity. Once this maximum value is exceeded, changing other conditions will no longer increase the shot peening intensity (the change trend is shown in Figure 1).

Figure 1: Graph of Shot Peening Intensity Changes

1.1 The physical meaning of shot peening intensity: In the industry, we generally use "shot peening intensity" as a parameter to control the depth of the residual compressive stress layer introduced on the surface of the workpiece by shot peening. Under the condition that other parameters remain unchanged, as the shot peening intensity increases, the depth of the residual stress layer introduced will also increase. This relationship can be understood by referring to Figure 1. We know that the depth of the residual compressive stress layer is directly related to the shot peening intensity of the shot peening beam. The unit of shot peening intensity is the same as that of the depth of the residual compressive stress layer, both being millimeters (mm) (or one thousandth of an inch).

1.2 Factors affecting shot peening intensity - Distance between nozzle and workpiece: In the actual equipment design, when the shot is ejected from the nozzle, it continues to be accelerated by the fast-moving air flow and decelerated by the resistance of the surrounding still air flow. The combined effect of acceleration and deceleration causes the shot to reach a maximum velocity at a certain distance (for general shot peening equipment, this distance is usually 200 to 300 mm). For shot blasting equipment, the shot immediately decelerates once it leaves the blade. This is why some companies' equipment operation manuals or SOPs require that the operator maintain a distance of 200 to 300 mm between the nozzle and the workpiece during shot blasting, in order to obtain the maximum shot peening intensity.

1.3 Factors affecting shot peening intensity - Shot peening time: To achieve the set shot peening intensity, a certain shot peening time is required. After a certain period of time, when the shot peening intensity reaches saturation, further extending the shot peening time will not significantly increase the intensity.

1.4 Factors affecting shot peening intensity - Shot peening flow velocity: To achieve the set shot peening intensity, the higher the shot peening flow velocity, the stronger the shot peening intensity. Once a certain shot peening intensity is reached, further increasing the shot peening flow velocity will not significantly increase the intensity.

1.5 Factors affecting shot peening intensity - Shot peening flow rate: To achieve the set shot peening intensity, the higher the shot peening flow rate, the stronger the shot peening intensity. Once a certain shot peening intensity is reached, further increasing the shot peening flow rate will not significantly increase the intensity. In summary, it can be found that before the shot peening intensity reaches a certain level, all influencing factors are almost directly proportional to the shot peening intensity. When the shot peening intensity reaches a "certain value", it almost no longer changes. Although shot peening intensity represents the potential shot peening intensity of the shot peening beam, the final reflected data needs to be demonstrated by the workpiece.

2. Shot Peening Intensity Identification and Measurement

"Shot peening intensity" is a parameter that defines and controls the ability of a shot peening beam to introduce a residual compressive stress layer. In the early stages of shot peening process development, J.O. Almen recognized the need to quantify this ability. He came up with an excellent idea, which was to use an indirect method to characterize the ability of the shot peening beam to introduce a residual compressive stress layer. This was achieved by shot peening a set of steel test specimens for gradually increasing periods of time and then testing the arc height values of the specimens to generate a "saturation curve". The "saturation curve" is used to describe the phenomenon that the arc height value of the shot peened specimens increases with the increase of shot peening time. "Shot peening intensity" is a specific point (saturation point) on the saturation curve, which is used to quantify the ability of a shot peening beam to introduce a deep residual compressive stress layer. The higher the arc height value of the specimen at the saturation point, the stronger the ability of the shot peening beam to introduce a deep residual compressive stress layer. Standards J442 and J443 describe how to calculate shot peening intensity using equipment and procedures.

So far, there is no practical method to directly test the potential shot peening intensity of a shot peening beam. Currently, we have to rely on characterizing the shot peening beam by testing its impact effect on Almen strips at 90°. The testing method for shot peening intensity is detailed in the standard SAEJ443. It requires testing a group of Almen strips for their arc height values after different shot peening times, and plotting a graph with time (or a parameter related to time) on the x-axis and arc height values on the y-axis. If we used an infinite number of Almen strips for shot peening at different times, we would obtain a continuous "saturation curve". Of course, this is impractical. In actual experiments, the data is limited, and usually 4 to 8 Almen strips are used.

Vigor team has more than 20 years experience in casting, forging, cold forming processes and the post treatment, as well as a robust surface treatment supply chain. If anything we can help or any parts you want to develop, please contact us at info@castings-forging.com