Knowledge

Procast Casting Process Solutions

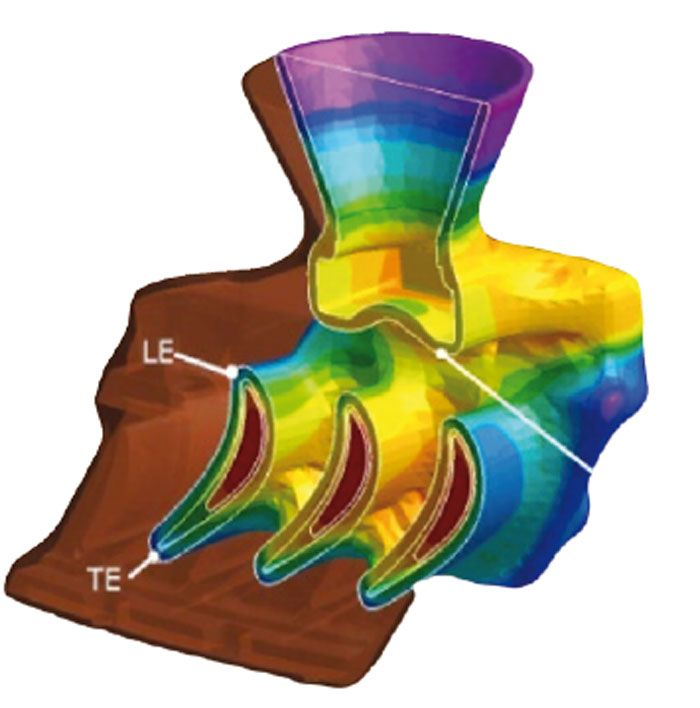

Precision Casting Simulation (Investment Casting)

Simulate casting in lost wax, from shell formation to pouring in air or vacuum. In investment casting, radiation is a decisive factor in solidification evolution and shrinkage porosity formation. Therefore, ProCAST is the only simulation software that can consider the two key elements of radiation: emissivity and view factor. ProCAST can automatically generate a mesh representing the shell mold suitable for investment casting and hot forming processes. Additionally, it focuses on meeting the specific needs of investment casting foundries, such as allowing for non-uniform shell layers and creating multiple shell layers. Moreover, it takes into account radiation with view factors, including shadow effects, which are fundamental for high-temperature alloys.

ProCAST is the most advanced investment casting simulation software. It offers a complete set of modules and casting tools to meet all contemporary industrial needs. Based on powerful finite element technology (FEM), ProCAST can predictively evaluate the entire casting process, including filling and solidification defects, mechanical properties, and complex part deformation. It allows for rapid visualization of the impact of design changes and provides a basis for the correct decision-making process from the earliest stages of production. ProCAST enables modeling of all casting processes for all casting alloys and also involves .other related casting production processes, such as core firing and heat treatment. ProCAST Investment Casting simulation software is designed to help users achieve cost reduction and shorten product development time

Squeeze Casting Simulation

Simulation of the solidification stage of forged parts in liquid casting alloys. Liquid forging is a unique light alloy fusion technology that involves applying very high pressure on the liquid material during the solidification stage. During the solidification simulation, the evolution of the solid part is calculated and used to predict the withdrawal position. The main challenge for simulation software suitable for liquid forging is the ability to accurately represent the filling of the mold, the solidification and cooling behavior of the liquid forged part before each production process begins. This avoids material waste and pre-production time, helps reduce or eliminate tool modifications, and thus saves a significant amount of energy, material costs, and tools. The liquid forging simulation process in ProCAST provides an accurate representation of the entire process, including analyzing the filling behavior of molten metal, the influence of various vent designs on return pressure, solidification, and the formation of shrinkage porosity. The benefits of liquid forging simulation include better quality, reduced development time; energy cost savings, material and tool modification savings, and design and optimization tools for the simulation process, which can develop better conditions suitable for real-time production. This simulation provides effective solutions to the technical challenges brought about by the new market opportunities created by this hybrid process.

Lost foam casting simulation

Simulate the pyrolysis phenomenon of polystyrene, the gas release from sand and the filling form. The simulation software ProCAST includes all the necessary functions considering liquid metal and the iterative influence between foams during the lost foam casting process, the model of liquidation and pyrolysis of foams, the transmission of gas products, the influence of ceramic coating on the mold, and the influence of gas trapped in the movement of liquid metal.

Simulating the Disappearing Foam Process

ProCAST offers a complete set of modules and casting toolkits to meet all contemporary industrial needs. Based on powerful finite element technology (FEM), ProCAST can predictively assess the entire casting process, including filling and solidification defects, mechanical properties, and complex part deformation. It allows for rapid visualization of the impact of design changes and provides a foundation for the correct decision-making process from the earliest stages of production. ProCAST enables modeling of all casting processes for all castable alloys and also involves other important production processes in foundries, such as core firing and heat treatment. QuikCAST is a fast and effective solution for evaluating the entire process. The software addresses the fundamental principles of any casting process: filling, solidification, and porosity prediction, including core burning and semi-solid modeling. QuikCAST is designed to help users reduce costs and shorten product development time. It can be used in the early stages of mold and process development and also for assessing the quality of castings.

Centrifugal simulation

Through the ProCAST centrifugal simulation software, the vertical centrifugal machine injection is simulated by considering the centrifugal force and Coriolis force, including the influence of these forces on porosity prediction. During the simulation process, the mold is rapidly rotated around its vertical axis while the metal is being poured. The fluid flow equations are solved in the relative velocity (rotating) reference system. ProCAST is the most advanced centrifugal simulation software. It provides a complete set of modules and casting tools to meet all contemporary industrial needs. Based on powerful finite element technology (FEM), ProCAST can predictively evaluate the entire casting process, including filling and solidification defects, mechanical properties, and complex part deformation. It allows for rapid visualization of the impact of design changes and provides the basis for the correct decision-making process from the earliest stage of production. ProCAST allows for modeling of all casting processes for all casting alloys and also involves other related casting production processes, such as core baking and heat treatment.

Vertical centrifugal casting simulation

QuikCAST is a fast and effective solution for evaluating the entire process. The software addresses the fundamental principles of any casting process: filling, solidification and porosity prediction, including core burning and semi-solid modeling. QuikCAST is designed to help users reduce costs and shorten product development time. It can be used in the early stages of mold and process development, as well as for evaluating the quality of castings.

Continuous casting simulation

Simulate the entire continuous casting line, from the tundish to the mold and secondary cooling. ProCAST continuous casting simulation software provides a complete solution for continuous and semi-continuous casting processes, including direct chill (DC) casting simulation. The software can simulate steady-state conditions as well as the initial and final stages of the continuous casting process. The MiLe algorithm can also be used for research on continuous casting processes. ProCAST also offers a unique feature: user functions allow more advanced end users to program their specific process requirements. For example, user functions allow you to define boundary conditions such as time, temperature and space-related, to precisely model any specific casting process. ProCAST and QuikCAST are production-oriented tools and therefore easy to use. Technical operators, quality and technical offices will use simulation daily to solve problems with workpieces. The software guides users step-by-step in importing geometry, selecting materials and setting process parameters. This activity requires minimal commitment from employees. At the same time, the R&D department can also use both software to produce new products. Additionally, thanks to the continuous casting simulation software ProCAST and QuikCAST, the best conditions can be obtained in the early stages of mold and process development and in the evaluation of casting quality to achieve healthy and almost defect-free components. ProCAST and QuikCAST software are suitable for desktop PCs or workstations.

High-pressure die casting - vacuum compression simulation

The simulation of forced exhaust is completed using a vacuum system, cooling blocks and valve suction devices. During filling, there are two competing fluids, the inlet alloy and the outlet air. Problems arise when the alloy contains air. ProCAST and QuikCAST software can be connected to the latest FONDAREX and Vacural vacuum technologies, and then the gas evacuation curve is controlled through the injection curve. The calculation of air back pressure and sufficient user-defined pressure conditions allow the simulation of the vacuum melting process.

With ProCAST and QuikCAST vacuum casting simulation software, the best conditions can be achieved to obtain healthy and almost defect-free parts. The software has a very user-friendly and easy-to-use graphical interface, requiring minimal commitment from employees: the program guides users step-by-step in importing geometry, selecting materials and setting process parameters. A unique thermodynamic calculator database allows users to directly input the chemical composition of the alloy and automatically predict the temperature-dependent properties required for an accurate simulation of the casting process. During solidification simulation, the evolution of the solid part is calculated and used to predict the withdrawal position. In vacuum processes, gas porosity due to undissolved hydrogen, stresses in the castings, stresses released upon mold removal, and the ejection and mold life of the components can all be predicted to reduce costs. The performance of production and use of components.

Steel ingot simulation

Simulate cast ingots with multi-directional unidirectional plates, completely filling columns and roots. Today, reducing costs and shortening marketing time are the two most urgent issues in the casting industry. With simulation software ProCAST and QuikCAST, you can perform a complete simulation of the ingots in your foundry and obtain actual predictions for each step of the casting process. Considering air back pressure, filters, mold roughness, heat exchange, mold coatings and gravity, it can precisely simulate most of the melting processes from sand to gravity, to high and low pressure die casting, applicable to all types of casting alloys. The verified technology of ProCAST and QuikCAST simulation software is based on a powerful solver with efficient self-correction capabilities, providing complete and practical results without relying on the grid. ProCAST and QuikCAST software have an innovative and easy-to-use graphical interface. They guide users step-by-step in importing geometry, selecting materials and setting process parameters. This activity requires minimal commitment from employees. The next step is to calculate the simulation and visualize how the software completes the process. Traditional 6, 8 and 12-core workstations are the computers that can reduce the waiting time for completing the simulation to a few hours. As a result, the ingot simulation software automatically displays the defects and problems that may occur in the mold in the department. ProCAST and QuikCAST software are suitable for desktop PCs or workstations.

Low-pressure simulation

Low-pressure simulation is completed starting from the flow tubes with and without cores. A complete low-pressure simulation can be divided into three main levels to be able to simulate different factors and make a final assessment of the overall framework of the process: filling, solidification, and stress evaluation (including the simulation of stress and deformation). Through low-pressure simulation, the basic steps for specifically assessing any defects by means of relative correction and possible changes in the initial model can be evaluated. ProCAST and QuickCAST simulation software are equipped with a complete set of dedicated tools for creating models of the low-pressure casting process.

Low-pressure simulation

During solidification simulation, the evolution of the solid part is calculated and used to predict the withdrawal position. The calculation of air back pressure, together with appropriate user-defined pressure conditions, allows the simulation of the vacuum die-casting process. ProCAST and QuickCAST allow the acquisition of process conditions by performing different production cycles to achieve stable mold temperatures, thereby enabling the study of filling, solidification, pressure enhancement effects, and the optimization of design and process parameters. Vacuum processes, including gas porosity due to undissolved hydrogen, stresses in the castings, stresses released upon mold removal, and the ejection and mold life of the components, can be predicted to reduce costs. The performance of production and use of components. Special requirements, including compression, semi-solid materials, cold chamber injection chamber models, suction models for hot chamber machines, and riser models in low-pressure casting systems, can be met.

Sand shooting

Cold box cores, inorganic Cordis, Inotec, Awb shooting and venting. Complete simulation of filling and hot core box. Traditionally, core production is subject to defects due to poor compaction of sand, low resistance, and poor surface finish, resulting in long and expensive development trials and errors in finding the most suitable process parameters. These typical basic defects are also the main cause of the high scrap rate in the casting industry. With the availability of numerical simulation solutions, the main process parameters can be optimized and made reliable, achieving actual cost and quality. The core shooting module of ProCAST simulation software can predict blow and venting defects, including incomplete filling, smaller compaction and hardening areas; it can predict the behavior of sand and gas flow during the blowing stage of the soul creation process. ProCAST is a successful product that has proven that numerical simulation can be an economical and effective alternative to the long-term trial and error development process.

ProCAST and QuikCAST software feature innovative and user-friendly graphical interfaces. They guide users step-by-step through importing geometries, selecting materials, and setting process parameters. This activity requires minimal commitment from employees. The next step is to run the simulation, during which the software visualizes how the process is completed. Traditional 6, 8, and 12-core workstations are the computers that can reduce the waiting time for completing the simulation to just a few hours. With the results in hand, the simulation software automatically highlights the defects and issues that the casting could have in the department. ProCAST and QuikCAST software are suitable for desktop PCs or workstations.