The ferrite ratio in carbon steel has a significant impact on the performance of automotive ball cage products. Ferrite is a basic microstructure in carbon steel, with a relatively low carbon content and good plasticity and toughness. When ferrite accounts for a relatively high proportion in carbon steel, the material exhibits better plasticity and toughness and is prone to deformation rather than fracture. However, an excessively high proportion of ferrite will lead to a decrease in the hardness and strength of carbon steel, restricting its application in certain high-load or environments requiring wear resistance.

2025-02-25 18:21:51

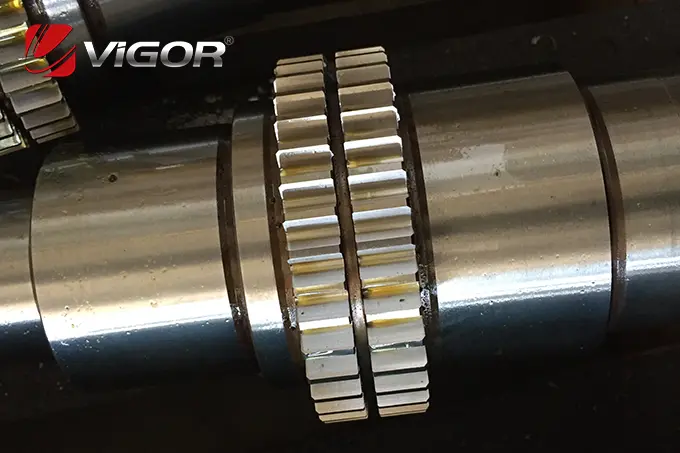

A spline shaft is a mechanical component designed to transfer torque while maintaining precise alignment between connected parts. It features a series of ridges or teeth that fit into corresponding grooves in a mating component, such as a gear, coupling, or hub. This interlocking mechanism ensures efficient power transmission, minimizes slippage, and enhances mechanical stability. Spline shafts are widely used in automotive, aerospace, and industrial machinery applications, where precision and durability are crucial. They come in various designs, including involute, straight-sided, and serrated splines, each tailored to specific performance needs. By distributing torque evenly across the contact surfaces, spline shafts reduce wear and tear, extending the lifespan of mechanical systems.

2025-02-25 10:28:09

A standard size knife gate valve is a critical industrial component designed for isolating and controlling the flow of dense, abrasive, or viscous materials. These valves are typically characterized by their streamlined design, which features a sharp-edged gate that slices through thick media such as slurry, pulp, or wastewater. Standard sizes for knife gate valves are determined by industry norms and application requirements, commonly ranging from 2 inches (50mm) to 48 inches (1200mm) in diameter. The exact size depends on the specific industrial application, such as mining, wastewater treatment, or paper production. Selecting the appropriate standard size ensures optimal performance, reliability, and efficiency in managing flow processes.

2025-02-25 10:28:04

Knife gate valves are essential components in industrial systems, designed to control the flow of media in pipelines. They are particularly effective for handling thick, viscous, or abrasive materials like sludge, slurry, and bulk solids. These valves are widely used in industries such as mining, wastewater treatment, pulp and paper, and power generation, where efficient handling of challenging media is crucial. Their unique design, featuring a sharp-edged gate, allows them to cut through and isolate flow, making them ideal for applications where other valve types might struggle. With their durability and reliability, knife gate valves help optimize system performance and reduce downtime across various industrial sectors.

2025-02-25 10:26:59

Knife gate valves are indispensable components in industrial settings where handling heavy-duty media such as slurry, pulp, or abrasive materials is required. These valves are specifically designed to provide reliable performance in environments where conventional valves might fail due to clogging, wear, or corrosion. Their ability to "cut through" thick and viscous substances makes them essential in industries such as mining, wastewater treatment, power generation, and paper production. Depending on the working environment, knife gate valves are crafted using high-quality materials to ensure durability, efficiency, and long-term performance. Below, we explore the primary environments where these valves excel and why they are the preferred choice for challenging applications.

2025-02-24 10:12:58

2025-02-24 10:12:47

2025-02-24 10:12:36

There are two types of high-frequency quenching heating methods: The first one is simultaneous heating and quenching, which involves heating the surface of the workpiece that needs quenching simultaneously and then rapidly cooling it; the second one is sequential continuous heating and quenching, where a small part of the surface of the workpiece is heated by induction heating, while the workpiece moves downward, allowing for sequential and continuous heating and cooling of the surface.

2025-02-21 19:22:05

Precision manufacturing of transmission shafts has seen significant advancements in recent years, driven by the need for higher durability, efficiency, and cost-effectiveness. Modern techniques focus on improving material properties, refining machining accuracy, and enhancing quality control. Leading innovations include advanced forging methods, high-precision CNC machining, and automated quality inspection technologies. These advancements help manufacturers produce more reliable and high-performance transmission shafts, reducing defects and ensuring optimal performance in various industries, from automotive to heavy machinery.

2025-02-21 09:39:51

When selecting a transmission shaft for industrial applications, customization is crucial to ensuring optimal performance, durability, and efficiency. Various industries, including automotive, heavy machinery, and renewable energy, require shafts tailored to specific operational demands. Customization options include material selection, surface treatments, heat treatments, precision machining, and special coatings. These modifications enhance strength, wear resistance, and overall longevity. Manufacturers like VIGOR INNO-TECH Limited, with over 18 years of expertise in castings and forgings, offer a full range of customization services, ensuring that every shaft meets technical and economic requirements. Understanding these options allows businesses to optimize their machinery for maximum efficiency and minimal downtime.

2025-02-21 09:39:42

2025-02-21 09:39:33

Transmission shafts play a crucial role in mechanical power systems, transmitting torque and rotation between different components. To ensure optimal performance, durability, and efficiency, manufacturers carefully select materials that provide the right balance of strength, toughness, and wear resistance. The most commonly used materials for transmission shafts include carbon steel, alloy steel, stainless steel, and specialized composite materials. Each of these materials offers distinct advantages depending on the application, operating conditions, and required mechanical properties. Understanding these material choices can help industries optimize performance, reduce maintenance costs, and enhance the reliability of their machinery.

2025-02-21 09:39:22

367