Knowledge

Magnesium alloy forging

I. Characteristics of Magnesium Alloys and Advantages of Forging

Magnesium alloys, with a density ranging from 1.74 to 1.85 g/cm³ (lower than the 2.7 g/cm³ of aluminum alloys and the 7.8 g/cm³ of steel), are key materials for lightweighting (Reference [1]).

The high strength-to-weight ratio

The tensile strength of AZ80 magnesium alloy can reach 380 MPa, approaching that of certain aluminum alloys (such as 6061-T6 at 310 MPa) (Reference [2]).

Damping property

The damping coefficient of magnesium alloys is 10 to 25 times that of aluminum alloys, making them suitable for precision instruments (Reference [3]).

Forging enhances performance. After forging, the grain size is refined to 10-20 μm (typically 50-100 μm in the as-cast state), and the strength is increased by 20-30% (Reference [4]).

II. Forging Process Parameters (Based on Experimental Research)

Temperature range

For AZ series magnesium alloys: The optimal forging temperature is 350 - 450℃ (avoid temperatures below 300℃ to prevent cracking and above 480℃ to prevent oxidation) (Reference [5]).

Mold preheating: 250 - 350℃, to reduce thermal stress (recommended by ASM Handbook [6]).

Strain rate control

The strain rate for hot forging of magnesium alloys should be less than 1 s⁻¹; otherwise, cracking may occur (experimental data see reference [7]).

Isothermal forging application

Isothermal forging of ZK60 magnesium alloy for aviation at 400℃ can increase the uniformity of deformation by 40% (Reference [8]).

III. Technical Challenges and Solutions

Oxidation and Combustion

Magnesium oxidizes rapidly above 400°C and requires protection with a 0.5% SF₆ + CO₂ gas mixture (industry standard [9]).

The plastic limit

The elongation of magnesium alloys at room temperature is only 5-10% (it can be increased to over 50% during hot forging) (Reference [10]).

The anisotropy of the basal texture (0001) after forging reaches 15-20%, and multi-directional forging is required for optimization (Reference [11]).

IV. Typical Application Cases

In aerospace, the Boeing 787 uses MB15 magnesium alloy forged landing gear brackets, reducing weight by 25% (Boeing Technical Report [12]).

In the automotive industry, the Audi A8 uses AZ31 magnesium alloy forged instrument panel crossbeams, reducing weight by 60% compared to steel parts (SAE paper [13]).

3C electronics

The Sony VAIO series notebook adopts an AM60 magnesium alloy forged shell, with a thickness of only 0.8 mm (patent US20150004425[14]).

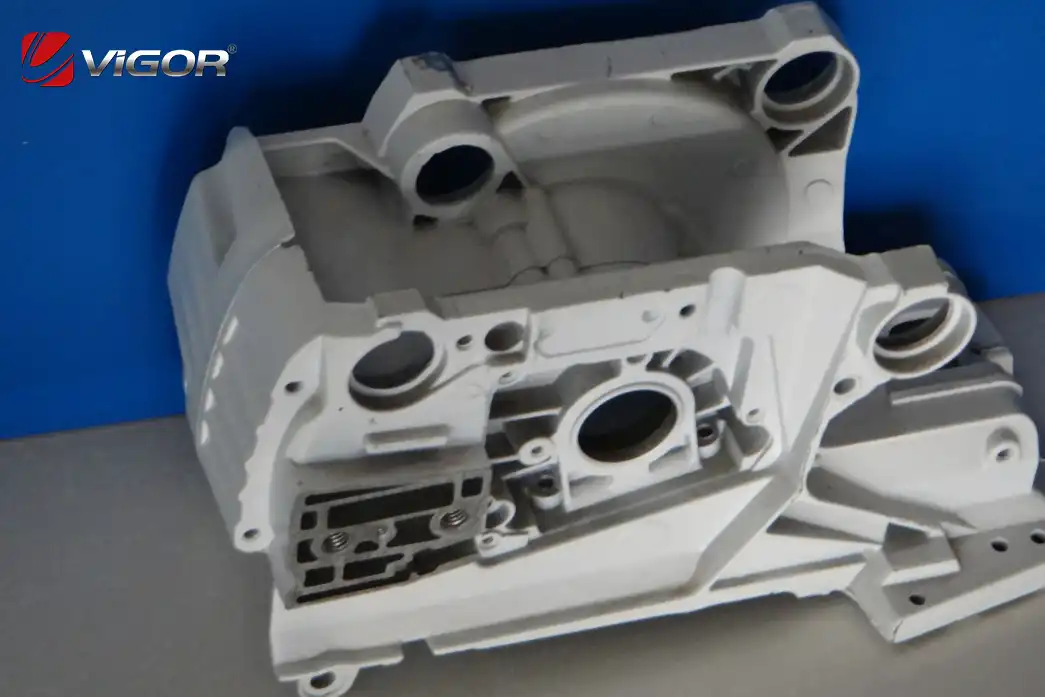

Vigor has mass high-quality resources on our Shanxi province, here has the complete industry and production system and supply chain from magnesium ore to finished magnesium alloy products. If you have any question, demand, related parts development or improve your supply chain, please feel free to contact us at info@castings-forging.com