Knowledge

Investment Casting Shell Making-Flash and Burrs

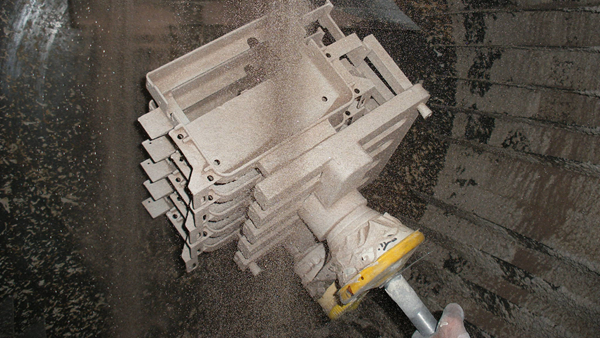

The defects of flash and burrs usually appears in the form of a straight or zigzag line and often occurs on the curved surfaces, edges, and corners of castings, as well as the inner corners of elbow products. The most direct cause is that the shell has cracks before pouring. During pouring, the molten steel seeps out along the cracks, similar to the process of "fire running" in the inner cavity, but the formation mechanism is different. Most of these cracks occur during the dewaxing process.

1. Insufficient pressure or slow pressure increase, causing the shell to crack during dewaxing.

2. Poor wax drainage during dewaxing.

3. Large changes in environmental temperature.

4. Insufficient wet strength of the shell.

Here, the author has not listed all the possibilities but only a few of the most likely causes for this defect. Compared with the "vein" defect, this defect usually has only one or two lines on the surface and is relatively deep, unlike the "vein" defect which covers the entire surface. Therefore, the author believes that the formation mechanism is different. Although both are affected by environmental factors, compared with the shell cracking and molten steel leakage during pouring, this defect is less severe. Generally, the protrusion thickness is about the thickness of three layers of the shell, which should be due to the different degrees of cracking. When the crack is large enough for the molten steel to flow out, but after flowing a certain distance, the molten steel stops flowing due to the decrease in temperature and the narrowing of the crack width, resulting in this defect. In fact, after dewaxing, you can also find a small crack on the surface of the shell. If you pour hot water into the cavity, the water can seep out from the crack. If it can be found, some sealing measures can be taken. Some that cannot be found will not cause molten steel leakage during pouring, but will result in batch seam defects.

I. Insufficient pressure or slow pressure increase in the dewaxing pot

When your shell has batch cracks or this problem occurs repeatedly, it is necessary to check the working condition of your dewaxing pot. Currently, the dewaxing pot is generally required to reach a pressure of more than 6 kilograms within 10 seconds or 7 kilograms within 14 seconds, and it is best to maintain a pressure of more than 6.5 kilograms throughout the process. If the pressure of your dewaxing pot is consistently below 6.5 kilograms, it is necessary to inspect your equipment. At the beginning of dewaxing, the wax rapidly expands due to the heat conducted from the shell. Zhang Gong mentioned in the live stream that this expansion pressure should not be underestimated. Ice can burst water pipes and bottles. If the dewaxing pot cannot maintain sufficient pressure at this time, the weak parts of the shell will be cracked by the expansion force. Once one or two parts crack, the pressure is released, and no other parts will crack. Therefore, this defect usually does not cover the entire surface and is different from the surface layer cracking defect of the shell. This problem belongs to the equipment capacity.

II. Poor dewaxing

The general cause of poor dewaxing is the process design. In the process design, the dewaxing step is not fully considered. First, it may lead to too much residual wax and other defects; second, it may cause the shell to crack. Some companies often encounter the problem of mold head bottom cracking, especially for vertical three or four-piece mold heads, which is basically caused by poor dewaxing. This situation can be further divided into the following two reasons:

(1) Excessive loading, the shell requires a large amount of heat to warm up, but the equipment's heating capacity is insufficient, resulting in the temperature not rising in time. Temperature and pressure are directly related. For steam, it can only reach a certain temperature when it reaches a certain pressure. You can refer to the following table, the relationship between steam pressure and temperature (the data may vary in different sources, for reference only). Please check your equipment. When there is a large difference between pressure and temperature, please check the equipment.

Sometimes we may attribute the breakage to the thinness of the mold, but this situation usually occurs only with certain products. When using the same mold for other products, there are no issues. Generally, this is due to excessive tree formation in these products or the presence of areas that are difficult to de-wax. Adding pressure relief ports to the mold can usually solve this problem. As for other special circumstances during the operation process, we cannot analyze them all in detail.

III. Large Fluctuations in Environmental Temperature

In the previous section on basic knowledge (Series 9), we have analyzed the influence of environmental factors. Therefore, we will not go into such detail here. However, it is essential to pay attention to the temperature stability between the back layers. In some foundries, the temperature in the same drying room can fluctuate by more than 5 degrees within a day. Such fluctuations, not to mention the impact on dimensions, also pose a challenge to the strength of the shell. Another point to note is that during de-waxing, the time from pulling the shell out of the drying room to entering the de-waxing autoclave and sending gas should be controlled. Especially in summer, when the outside temperature is much higher than that in the drying room, some companies have a long distance from the drying room to the de-waxing autoclave, or workers are not careful and wait beside the de-waxing autoclave after pulling out the shell. There have even been cases where gas was forgotten to be sent after the shell was placed in the autoclave. Please pay close attention to this.

IV. Insufficient Wet Strength of the Shell

This problem often occurs in some large curved surfaces or corners because these areas tend to have concentrated stress, leading to cracks. In the entire shell, the area that is relatively weaker compared to others will crack first. Some inner corners may have insufficient drying, resulting in reduced wet strength. Regarding strength, it is related to factors such as people, materials, equipment, and environment. We have analyzed this in detail in the previous text and will not elaborate further here.

In fact, the causes of this defect are not limited to the above few points. These are just the more common reasons.

Vigor has more than 20 years experience and the professional team in castings and forging as well as the post of treatment processes. If you have any question or products need to do, please feel free to contact us at info@castings-forging.com