Knowledge

Heat Treatment Process for Eliminating the Forged Twinning Structure of 9Cr18Mo

Due to the poor thermal conductivity, high alloy content, narrow forging temperature range and high processing difficulty of 9Cr18Mo stainless steel, it is very easy to cause coarse forging structure and twin structure due to excessively high forging temperature and too long holding time. Twin structure has extremely strong heredity and stability, and it is difficult to eliminate through annealing and quenching treatment. Therefore, process tests were conducted on 9Cr18Mo stainless steel bearing parts with forged twin structure to study the feasibility of removing the forged twin structure of 9Cr18Mo stainless steel bearing parts through heat treatment methods.

1 Normalizing process

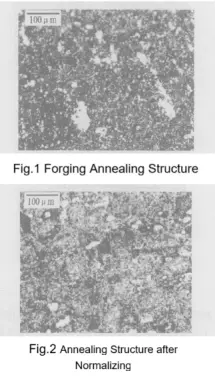

The stainless steel bearing outer rings with twinned carbides after forging annealing (Figure 1) were subjected to the following normalizing process. They were heated up to 1120℃ in a heat treatment furnace and held for 1.5 hours, then taken out and air-cooled to room temperature by spreading them out and blowing air. Subsequently, they were annealed in the RJX-60-9 furnace according to the stainless steel annealing process (annealing process: held at 910℃ for 2 hours, then cooled at a rate of 30℃ per hour to 550℃ and taken out for air cooling). It was found that 30% of the rings still had twinned structures (see Figure 2). During normalizing heating, the small grains were restored to the original austenite grains, and the spatial orientation basically did not change much. During normalizing cooling, one austenite grain was again divided into several small grains. Thus, although the coarse austenite grains before normalizing (i.e., after forging) were seemingly refined in form (divided into many small grains), in essence, since the orientation and size of many small grains were consistent with the original austenite grains, only a very small part of the twinned structure was reduced, while the majority was inherited. Normalizing can only remove relatively light twinned structures, and it is impossible to remove all twinned structures.

Double low-temperature decomposition + normalizing process

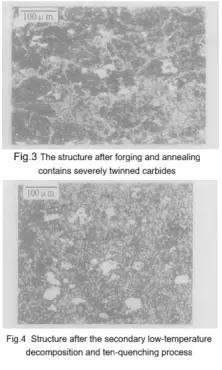

Three stainless steel outer rings with severe twinning structure (Figure 3) were subjected to low-temperature decomposition in the RJX-60 furnace. The process was as follows: holding at 690°C for 3 hours, then air-cooling to room temperature; repeating the process of holding at 690°C for 3 hours and air-cooling to room temperature; followed by normalizing in the RJX-50-13 furnace, with the process being: heating up to 1120°C in the furnace and holding for 1.5 hours, then air-cooling to room temperature after removing from the furnace; finally, the three outer rings were annealed according to the stainless steel annealing process. The results showed that all the twinning carbides in the three stainless steel outer rings were eliminated (see Figure 4). Through the above test results, it can be known that: ① Using two times of low-temperature decomposition at 690°C can make all austenite decompose. ② After heating to the normalizing temperature, ferrite transforms into austenite and undergoes another phase transformation. Due to the temperature non-uniformity, micro-region stress and deformation occur, resulting in high-temperature deformation recrystallization, which can destroy the stubborn grain boundaries of the original austenite and eliminate the coarse twinning structure. However, this process cannot eliminate particularly severe forging twinning structure.

Three low-temperature decomposition + normalizing process

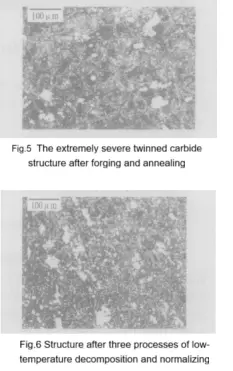

Four stainless steel inner rings with particularly severe twinning structures (Figure 5) were subjected to process tests. They were placed in the RJX-60 furnace for three low-temperature decompositions, with each process involving holding at 690°C for 3 hours, followed by air cooling to room temperature. Then, they were placed in the RJX-50-13 furnace for normalizing, with the process being: heating up to 1110°C in the furnace and holding for 2 hours, then taken out and air-cooled to room temperature by spreading out and blowing air. The four inner rings were then annealed according to the stainless steel annealing process. After checking the annealing structure, it was found that two were qualified, and two still had twinning structures, but the originally severe twinning structures had been greatly improved, with only very small twinning carbides remaining in some local areas (see Figure 6).

From the above experimental results, it can be known that for particularly severe twinned microstructure, even by increasing the number of low-temperature decomposition and repeatedly undergoing phase transformation, it is impossible to completely eliminate the twinned carbide microstructure.

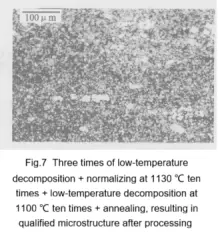

To ensure the complete removal of all twin structures, a new process was developed. According to the Fe-Cr-C phase diagram of 9Cr18Mo steel, after low-temperature decomposition, the microstructure is ferrite α and secondary carbides (Fe, Cr)23C6. Between 900 and 940°C, ferrite α transforms into austenite γ, and the resulting microstructure is γ + (Fe, Cr)23C6. Austenite γ nucleates and grows around dispersed carbides K. According to thermodynamics, the nuclei should grow freely and disorderly, thereby disrupting the original grain orientation relationship. To consolidate the new grain boundaries, a long isothermal holding is necessary to achieve a stable state for the new grains. Then, the γ + (Fe, Cr)23C6 is rapidly heated to the γ + primary carbide (Fe, Cr)7C3 region, i.e., high-temperature normalizing, to induce high-temperature deformation recrystallization, disrupt the original austenite stubborn grain boundaries, and eliminate the twin structures. To ensure the complete removal of twin structures, an additional low-temperature decomposition + normalizing process was added to achieve repeated phase transformation, grain refinement, and improved impact toughness.

A total of 144 stainless steel outer rings and 144 stainless steel inner rings were trial-produced using the following process. Three low-temperature decompositions were carried out in the RJX-60 furnace, with each process involving holding at 690°C for 3 hours, followed by air cooling to room temperature. Then, normalizing was performed in the RJX-50-13 furnace, with the process being: heating up to 920°C and holding for 2 hours, then heating up to 1130°C and holding for 1.5 hours before removing from the furnace and air cooling to room temperature with the parts spread out and blown by air. A total of 6 furnaces were processed, with 24 parts in each furnace. The normalized inner and outer rings were then subjected to low-temperature decomposition in the RJX-60 furnace, with the process being holding at 690°C for 3 hours, followed by air cooling to room temperature. Then, normalizing was performed again in the RJX-50-13 furnace, with the process being heating up to 920°C and holding for 1.5 hours, then heating up to 1100°C and holding for 1 hour before removing from the furnace and air cooling to room temperature with the parts spread out and blown by air. Finally, the inner and outer rings were annealed according to the stainless steel annealing process. 15 parts from each furnace were randomly inspected, and the annealing microstructure was found to be all qualified, with no twin carbide structures (see Figure 7).

5 Conclusions

(1) For relatively light twinned carbides after forging and annealing, a secondary low-temperature decomposition + normalizing process can be adopted to eliminate the twinned carbide structure.

(2) For extremely severe twinned carbides after forging and annealing, a three-step low-temperature decomposition + normalizing at 1130°C process + one-step low-temperature decomposition + normalizing at 1100°C process can be used to eliminate the twinned carbides.

Vigor team has more than 20 years experience in casting, forging, cold forming processes and the post treatment, as well as a robust surface treatment supply chain. If anything we can help or any parts you want to develop, please contact us at info@castings-forging.om