Knowledge

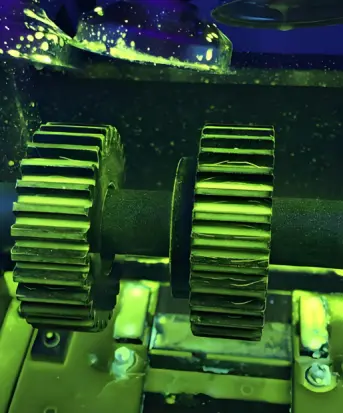

Gear Failure (III)

Prevention of Gear Tooth Breakage and Pitting

I. Preventive Measures for Gear Fracture Failure

1.1 Design Optimization

Reduce stress concentration: Increase the fillet radius at the tooth root and use modified gears (such as helical gears). Select materials appropriately: Use high-strength alloy steels like 18CrNiMo7-6 for heavy-duty gears and apply nitriding treatment for high-speed gears.

1.2 Manufacturing Process Control

Heat treatment: Ensure precise quenching and tempering process parameters (e.g., avoid quenching cracks).

Surface strengthening: Use shot peening or laser shock peening to enhance the fatigue resistance of the tooth surface.

1.3 Operation and Maintenance Management

Lubrication maintenance: Regularly replace lubricating oil to prevent abrasive wear-induced cracks. Condition monitoring: Early detection of tooth surface damage through vibration analysis or acoustic emission technology.

II. Preventive Measures for Gear Pitting Failure

2.1 Material Selection and Heat Treatment

Selecting Appropriate Materials: Based on the working conditions and performance requirements of gears, materials with good resistance to pitting should be chosen. For heavy-duty and high-speed gear transmissions, high-strength and high-toughness alloy steels should be preferred, and appropriate alloying treatments should be carried out to enhance the comprehensive performance of the materials.

Optimizing Heat Treatment Processes: Through reasonable heat treatment processes such as quenching, tempering, carburizing, and nitriding, the hardness and wear resistance of the tooth surfaces can be improved while ensuring that the materials have sufficient toughness. For example, for carburized gears, the depth and hardness gradient of the carburized layer should be strictly controlled to avoid situations where the surface is too hard while the core has insufficient toughness.

2.2 Optimization of Design and Manufacturing

Reasonable Design of Gear Parameters: During the gear design process, parameters such as module, number of teeth, and tooth width should be reasonably selected to reduce the contact stress on the tooth surfaces. For instance, appropriately increasing the tooth width can reduce the load per unit contact length, thereby lowering the contact stress. Additionally, employing suitable tooth profile modification techniques, such as profile modification and helical modification, can improve the contact conditions on the tooth surfaces and reduce stress concentrations.

Improving Machining Accuracy: Strictly control the machining accuracy of gears to ensure that machining accuracy indicators such as tooth profile error and helical error meet the design requirements. Utilizing advanced machining equipment and processes, such as CNC machining and gear grinding, can enhance the machining quality of gears, reduce the roughness and microscopic defects on the tooth surfaces, and thereby improve the pitting resistance of gears.

2.3 Strengthening Lubrication Management

Selecting Appropriate Lubricating Oil: Based on the working conditions of gears, such as load, speed, and temperature, select lubricating oil with appropriate viscosity and quality grade. At the same time, pay attention to the lubricating oil replacement cycle and replace the lubricating oil regularly to ensure its performance.

Optimizing Lubrication Methods: For high-speed and heavy-duty gear transmissions, efficient lubrication methods such as oil jet lubrication should be adopted to ensure that the tooth surfaces are adequately lubricated and cooled. Additionally, the cleanliness of the lubricating oil should be maintained to prevent impurities and moisture from entering the oil, which could affect the lubrication effect.

2.4 Strict Installation and Maintenance

Ensuring Installation Accuracy: During the installation of gears, operations should be carried out strictly in accordance with installation requirements to ensure that installation accuracy indicators such as parallelism of the gear shafts and center distance meet the requirements. At the same time, appropriate pre-tightening and adjustment of the gears should be performed to ensure uniform contact on the tooth surfaces.

Strengthening Daily Maintenance: Regularly inspect and maintain gears to promptly detect and address early damage and defects on the tooth surfaces. For example, clean the dirt and wear particles on the tooth surfaces, check the quality and quantity of the lubricating oil, etc. At the same time, monitor the vibration and noise of the gears to promptly identify abnormal conditions and take corresponding measures.

Summary

Gear breakage and pitting failure is a complex process, influenced by various factors such as material, load, lubrication, processing and installation. By thoroughly studying the mechanism and influencing factors of gear tooth breakage and pitting failure, and adopting appropriate detection methods to timely identify failure issues, as well as taking corresponding preventive measures, the occurrence of gear tooth breakage and pitting can be effectively reduced, thereby enhancing the service life and working performance of gears and ensuring the normal operation of mechanical equipment.