Knowledge

Eight Methods for Gear Machining

Gears are commonly used components in mechanical design. By the cooperation of two gears, power can be transmitted. The combination of large and small gears can change the output speed and torque, while the cooperation of bevel gears can change the direction of power output. There are various forms of gear tooth profiles, among which involute tooth profile is the most common. The common processing methods of involute tooth profile are divided into two major categories: forming method and generating method. Here, we will not explain them in detail. Next, we will focus on introducing the common processing methods of gears.

Milling, which requires disc-shaped module milling cutters and corresponding processing equipment. Milling teeth is processed by the forming method, and the cross-sectional shape of the milling cutter teeth corresponds to the shape of the gear tooth tip. This processing method has low efficiency and accuracy and is only suitable for single-piece or small-batch production.

Broaching, which is processed using a broach. Place the gear on the processing equipment, and then process the gear with a broach or broach disc to make the tooth surface reach the required precision and quality standards. It is often used for processing internal teeth or splined gears.

Hobbing, which requires a hobbing cutter and corresponding equipment and belongs to the formative method of processing. Its working principle is similar to the meshing of a pair of helical gears. The prototype of the gear hobbing cutter is a helical gear with a large helix angle. Due to the small number of teeth and long tooth length, it is wound around the shaft to form a worm with a very small helix angle. After grooving and back face shaving, it becomes a hobbing cutter with cutting edges and relief angles, which is used for gear processing.

Shaping, which uses a gear shaping cutter and can be used to process external or internal teeth. It is a commonly used form-generating gear cutting process other than hobbing. During gear shaping, the shaping cutter and the workpiece are similar to a pair of cylindrical gears in mesh. The reciprocating motion of the shaping cutter is the main motion, and the shaping cutter and the workpiece perform circular motion at a certain ratio, which is the feed motion of shaping.

Planing, which uses a planing machine and a forming tool. It is often used for processing bevel gears and the principle is relatively simple.

Shaving. In mass production, it is a commonly used finishing process for non-hardened gear teeth. The principle of shaving is that the shaving cutter and the gear to be processed engage freely, and fine chips are removed from the tooth surface by relative sliding to improve the accuracy of the tooth surface. It can also form barrel-shaped teeth and improve the position of the tooth surface contact area.

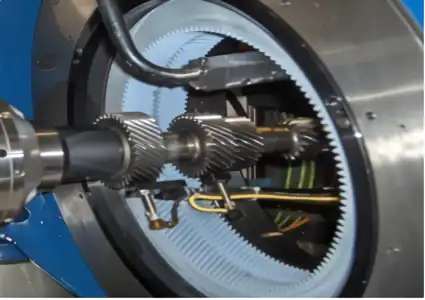

Honing, which is a precision finishing method. After quenching, the gear surface has oxide scale, which affects the surface roughness of the tooth. Heat treatment deformation also affects the accuracy. Besides grinding, honing can also be used for precision finishing. The principle of honing is similar to shaving. The honing wheel and the workpiece are similar to a pair of helical gears without backlash. Honing is carried out by the relative sliding at the meshing point and applying a certain pressure between the tooth surfaces.

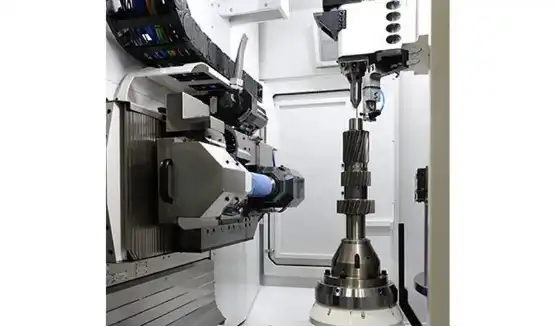

Grinding, which also belongs to the category of precision machining methods. It uses the generating method, and the cutting motion is similar to that of gear hobbing. It is an important precision machining method for gears, especially for hard-toothed gears. Generating method gear grinding can be carried out using worm-shaped grinding wheels, conical grinding wheels or disc grinding wheels.

Vigor has rich experience in producing high quality gear shafts, spline shafts and gear wheels. If you have any question, demand, new parts need to be developed or improve your supply chain, please feel free to contact us info@castings-forging.com