Knowledge

Discontinuities in Metallic Materials

The discontinuity of metallic materials refers to the non-uniformity and sudden changes in their internal structure, composition or performance. In the study of failure analysis cases, it is found that many failures are caused by the discontinuity of materials.

The discontinuity of structure is mainly reflected in two aspects: internal defects and the inhomogeneity of the organization.

Internal defects

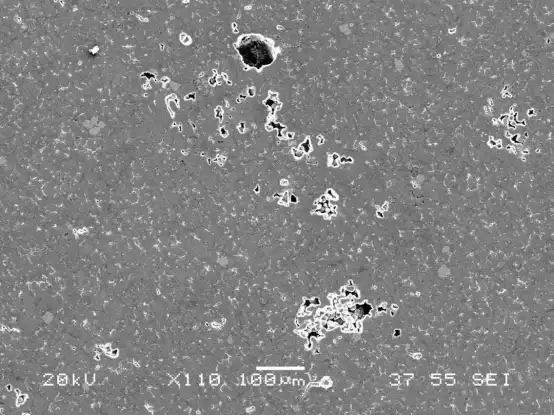

• Porosity: Cavities formed inside the metal due to gases not being able to escape in time during the metal melting and casting process. These pores disrupt the metal's continuity, reducing its effective load-bearing area and leading to a decrease in strength and toughness. Welded joints in welded parts often have porosity to varying degrees and quantities.

• Shrinkage cavities and porosity: Holes formed inside a casting due to volume contraction during the solidification of metal. They usually concentrate in the last solidified parts of the casting, causing discontinuity in the metal structure and reducing the mechanical and processing properties of the casting.

Cracks: In the processing or usage of metals, cracks are formed due to stress concentration, fatigue, brittleness and other reasons. Cracks are a serious discontinuity defect, which can become a stress concentration source, causing the metal material to fracture at a stress far below its strength limit, significantly reducing the reliability and service life of the material.

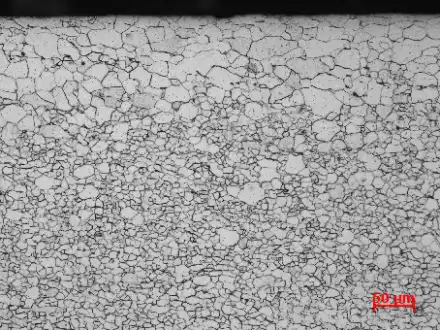

Inhomogeneous microstructure

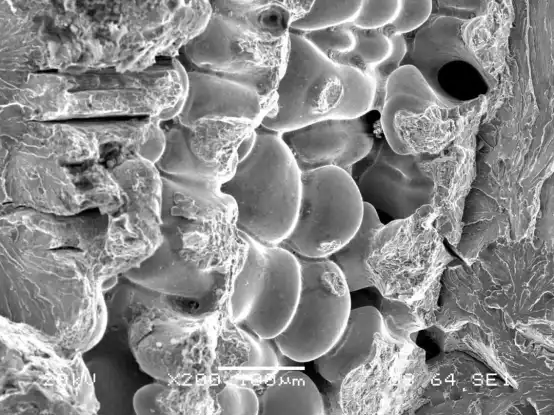

• Inconsistent grain size: Metal materials are composed of numerous grains. If the sizes of the grains vary significantly, when subjected to force, grains of different sizes will deform to different extents, and stress concentration is likely to occur at the grain boundaries, resulting in discontinuous mechanical properties of the material.

• Inhomogeneous phase composition: Metal materials may contain multiple phases, such as ferrite, cementite, and pearlite in iron-carbon alloys. Different phases have different properties, and the atomic arrangement at the phase interfaces is discontinuous. When the material is subjected to force or heat, the phase interfaces are prone to become weak links, affecting the overall performance of the material.

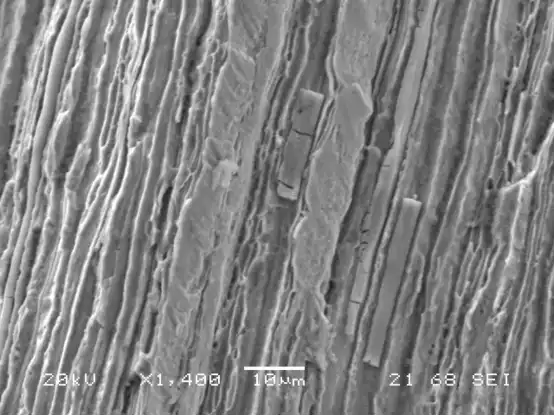

The second phase particles or constituent phases: The second phase of inclusions mainly originate from the solidification process of metal smelting. As shown in the following figure, long strip-shaped sulfide inclusions can split the matrix structure, significantly reducing the transverse performance of the metal material.

The discontinuity of composition is mainly caused by segregation: during the solidification of metals, due to reasons such as uneven cooling rates, alloy elements are distributed unevenly over a large range. For instance, in large ingots, there may be significant differences in chemical composition between the bottom and the top, which can lead to different properties in different parts of the material, causing problems for subsequent processing and use.

Not only do discontinuities in composition and microstructure occur during the metal melting and casting processes, but they can also be introduced during subsequent cold and hot working and heat treatment processes.

Cold working hardening: During the cold working process of metallic materials, the grains deform, the dislocation density increases, resulting in an increase in the material's strength and hardness, and a decrease in its plasticity and toughness. This performance change may have discontinuity between the processed and unprocessed areas, which can affect subsequent processing and usage.

• Inconsistent heat treatment: If the heating or cooling of metal materials during heat treatment is not uniform, it will lead to inconsistent microstructure transformation in different parts of the material, resulting in performance differences. For example, during quenching, the cooling rates of the surface and core of a part may differ, which may cause high surface hardness and low core hardness, leading to discontinuity in performance.

If you have any question, demand, new parts of ductile iron castings need to be developed or improve your supply chain, please feel free to contact us info@castings-forging.com