Knowledge

Diffusion welding - a New Welding Process

Having been engaged in the mechanical processing industry for over two decades, although I can't claim to be an expert in everything, I should at least have heard of all kinds of processes. Today, I came across a new process called "diffusion welding".

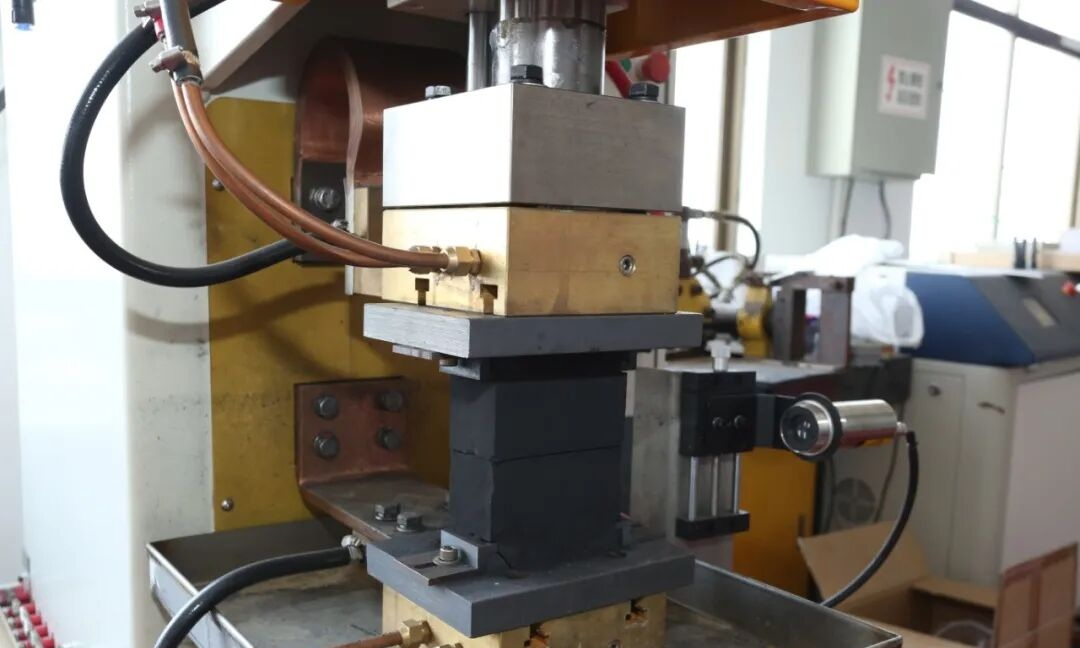

Diffusion welding is a solid-state welding method that forms a strong connection by making the surface atoms of the welded parts diffuse into each other under high temperature and pressure. It is suitable for dissimilar metals, heat-resistant alloys, ceramics and other materials, and has the advantages of high joint strength and small deformation.

Characteristics of diffusion welding:

● Welding process:

1. Closely fit the workpieces.

2. Heat to a temperature below the melting point of the base material in a vacuum or gas-protected atmosphere.

3. Apply pressure to break the surface oxide film.

4. Plastic deformation and high-temperature creep occur at microscopic protrusions, achieving close contact.

5. Atoms diffuse across the interface to form metallic bonds.

● Advantages:

○ Suitable for dissimilar metal materials, heat-resistant alloys, ceramics, and other new materials.

○ Maintains the stability of materials and structures.

○ High joint strength.

○ Minimal material deformation.

● Limitations:

○ Requires complex equipment, especially for vacuum diffusion welding.

○ High initial investment and relatively high cost.

Application fields of diffusion welding:

● New energy vehicle manufacturing, such as copper soft connection conductive products.

● Microchannel heat exchanger manufacturing.

● Aerospace, electronics, nuclear energy, and other fields.

Diffusion welding has unique advantages in the connection of new materials and complex structures. Despite the high equipment cost, it is widely used in specific fields.