Knowledge

Copper-manganese Alloyed Ductile Iron

To produce cast ductile iron parts with stable performance at a low cost, our company collaborated with a university to conduct research on copper-manganese alloyed cast ductile iron. The results were published in the journal "Foundry" that year.

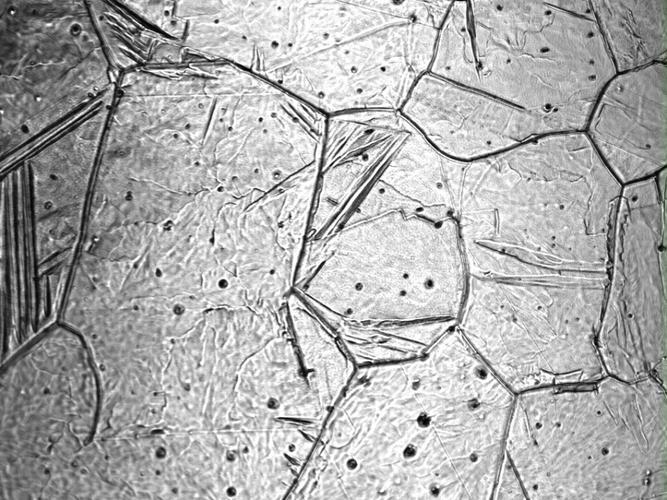

As the manganese content increases, the amount of pearlite in the structure increases, tensile strength and hardness increase, while elongation decreases. These effects of manganese are not gradual but occur within a critical range. Below or above this critical range, the influence is relatively slow. Therefore, to achieve high plasticity, the manganese content should be less than the critical range; to obtain high strength, the manganese content should be greater than the critical range. Beyond this point, further increasing the manganese content does not significantly improve the performance. The reason for the influence of manganese content on performance may be that when the manganese content is low, it dissolves in ferrite and has a solid solution strengthening effect; when the manganese content is high, it replaces iron or forms alloy cementite (Fe,Mn)3C with iron and carbon. This alloy cementite appears in the form of pearlite, which is conducive to the formation and refinement of pearlite, significantly increasing strength and hardness, and reducing plasticity. When the amount of pearlite is sufficiently high (about 80%), the promoting and refining effect of manganese on pearlite weakens, and the performance change is not significant. Copper can significantly refine pearlite, and its ability to promote pearlite is three times that of manganese. Copper is also a medium graphitizing element and can improve the stability of the austenite shell, which is conducive to obtaining round graphite. Copper and manganese alloys jointly promote the formation of pearlite, and the influence of the combination of copper and manganese on the structure and performance is shown in the following figure.

When the manganese content is constant, as the copper content increases, the pearlite content in the microstructure increases, the strength and hardness increase, and the elongation decreases. When the manganese content is low, the slope of the curve is large and the change rate is fast, indicating that copper has a strong ability to form and refine pearlite; when the manganese content is high, the slope of the curve is small and the change rate is slow, indicating that the effect of copper weakens. For a constant manganese content, the slope of the curve is large in the early stage and small in the later stage, meaning that the effect of copper is significant when the addition is small, and weakens when the addition is large. This indicates that the ability of copper to promote and refine pearlite is related to the amount of pearlite in the microstructure and weakens as the pearlite content increases. With a good copper-manganese ratio, the tensile strength can reach 700-800 MPa, and the elongation is around 5%.

One major obstacle in manganese alloying is the possible precipitation of carbides at the grain boundaries, which can affect the processing performance. No free carbides were observed in the metallographic examination. The hardness at the same wall thickness and different wall thicknesses of 15mm, 30mm, 50mm, and 70mm stepped test blocks was measured. From the four test blocks with high manganese content, it was found that the maximum hardness difference at the same wall thickness was 23HB, with the highest hardness being 265HB and the lowest being 232HB. The hardness distribution of stepped test blocks with higher copper and manganese content was also tested. The maximum hardness difference at the same wall thickness was 28HB, and the maximum average hardness difference at different wall thicknesses was 28HB. The processing performance feedback of the cast samples was good.

Based on the test results, under the premise of normal basic composition and good spheroidization quality, the recommended copper-manganese alloying production schemes for automotive parts are as follows:

QT500-7 ductile iron parts: Mn 0.7-0.9%

QT550-5 ductile iron parts: Mn 0.7-0.9%;

or Mn 0.4-0.6%, Cu 0.4-0.6%

QT600-3 ductile iron parts: Mn 0.6-0.7%, Cu 0.4-0.7%

QT700-2 ductile iron parts: Mn 0.6-0.8%, Cu 0.5-0.8%

Vigor team has more than 20 years experience in casting, forging, cold forming processes and the post treatment, as well as a robust surface treatment supply chain. If anything we can help or any parts you want to develop, please contact us at info@castings-forging.om