Knowledge

Comparison and Selection Guide of Commonly Used Forged Gear Wheel Materials

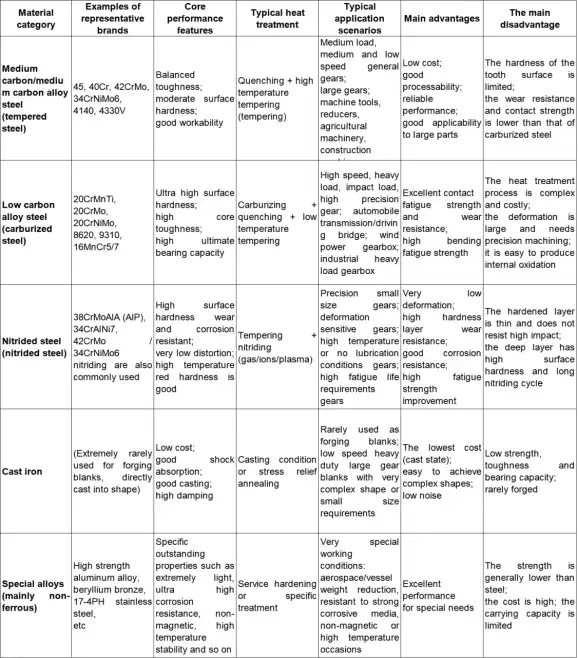

Practical Guidelines for Material Selection

- Starting Point Selection: If there are no special high requirements for specific applications, medium carbon alloy steel (such as 40Cr, 42CrMo) as quenched and tempered steel is a safe, reliable, and cost-effective starting point.

- Performance Priority: If the application involves high stress, impact, high speed, and long service life, carburizing steel (such as 20CrMnTi, 20CrNiMo, 8620, 9310) is the top choice.

- Precision and Temperature Resistance: For high precision, minimal deformation, and high-temperature conditions (<550℃), alloy steel with high nitriding potential (such as 38CrMoAlA, 34CrAlNi7, or high-quality 42CrMo/34CrNiMo6 for nitriding treatment) is preferred.

- Cost Sensitivity and Large Dimensions: For large-sized gears or general applications where cost is highly sensitive, quenched and tempered medium carbon steel or medium carbon alloy steel is the foundation.

- Extreme Requirements: For pursuing ultimate performance or under special physical and chemical conditions, consider special alloys (such as high-end bearing steel for precision instruments, high-speed steel for specific small gears, beryllium bronze for special environments, etc.).

China Vigor has more than 20 years of experience and a strong technical team and production capabilities in die-forging. If you have any questions, demand, related parts development or improve your supply chain, please feel free to contact us at info@castings-forging.com