Knowledge

Ceramic Foundry Sand (PART FIVE)

Application Data of Pearlite Sand in Large Cast Steel Parts

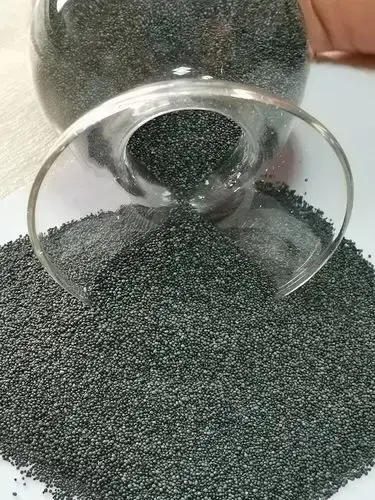

I. Basic Performance Parameters of Pearlite Sand

• Main Components: Al2O3 (75% - 80%), SiO2 (10% - 20%), and trace components such as TiO2 (≤ 3.5%), etc.

• Particle Shape: Spherical, with a low angularity coefficient (≤ 1.1), which is conducive to tight packing and uniform distribution.

• Refractory Temperature: ≥ 1800°C or higher, far exceeding traditional casting sands like silica sand.

• Thermal Expansion Coefficient: Extremely small within the range of 20 - 1000°C, which helps maintain the dimensional accuracy of castings.

• Bulk Density: 1.95 - 2.05 g/cm³, with a low bulk density, which helps reduce the amount of sand used.

• True Density: 3.4 g/cm³, with a moderate density, which is convenient for operation and processing.

II. Specific Application Data of Baozhu Sand in Large Cast Steel Parts

1. Surface Quality and Dimensional Accuracy of Castings

• Prevention of Sand Adhesion and Scabbing:

When a steel plant was manufacturing large cement production equipment, it used Baozhu sand as core sand. During cleaning, it was found that the surface of the core shell was smooth, without sand adhesion, and had not been sintered, making it easy to clean. In contrast, the areas using silica sand showed severe sand adhesion and scabbing.

• Improvement of Dimensional Accuracy:

• Baozhu sand has a small coefficient of thermal expansion, which helps maintain the dimensional accuracy of castings. For instance, when a casting plant was producing high-precision castings, the dimensional accuracy of the castings increased by approximately 20% after using Baozhu sand.

2. Production Efficiency and Economic Benefits

• Reduced Resin Addition:

• Due to the spherical particle shape and smooth surface of Baozhu sand, the binder can be more evenly distributed on the surface of the sand grains, thereby reducing the amount of resin added. According to data from a certain foundry, the resin addition was reduced by approximately 40% after using Baozhu sand.

• Increased Production Efficiency:

• Baozhu sand is easy to fill and compact, reducing the occurrence of sand inclusion defects and the amount of cleaning work, thereby increasing production efficiency. For example, a certain steel casting factory saw a production cycle reduction of about 30% after using Baozhu sand.

• Lowered Production Costs:

• After using Baozhu sand, overall production costs are reduced due to the decreased resin addition, shortened production cycle, and improved casting yield. Specific figures vary depending on the type of casting and production scale, but typically, costs can be reduced by about 10% to 20%.

3. Environmental Benefits

• Reduced waste sand discharge:

• The reusability of zircon sand is excellent, and it can be recycled repeatedly with minimal breakage. According to data from a certain foundry, the regeneration rate of zircon sand can reach up to 98%, significantly reducing the discharge of waste sand.

• Improved production environment:

• Zircon sand generates little or no dust and has a low content of silica dust, eliminating the risk of silicosis. After using zircon sand, the dust concentration in the workshop has decreased by approximately 50%, improving the production environment and reducing the health risks to workers.

Large cast steel parts usually require the pouring of tens of tons or even hundreds of tons of molten steel. Some sand cores are surrounded by a large amount of molten iron. The thermal effect of molten steel on molding materials lasts for a long time, and the static pressure head is also very high. The working conditions are extremely harsh. Therefore, chromite sand is widely used as facing sand in the production of large cast steel parts. Currently, the better quality chromite sand is high-quality imported foundry-grade chromite sand. Although the expansion rate of chromite sand is relatively low, its angularity coefficient is large, the particle shape is relatively poor, and the core fluidity is poor, which can lead to poor permeability and collapsibility in the later stage. In some cases (such as some thin-walled or blind hole sand cores), even chromite sand is difficult to clean out, which correspondingly increases the cleaning work of the castings.

Using zircon sand in the areas prone to sand sticking, such as inner corners, grooves, and fine long holes with concentrated heat in large cast steel parts, can eliminate local sand sticking or iron coating on the sand, reduce the cleaning cost of castings, and improve the surface quality of castings.

Vigor has more than 18 years experience on castings. If you have any question and demand of products development or improve your supply chain, please feel free to contact us at info@castings-forging.com