Knowledge

Ceramic Foundry Sand

Section 1: Ceramic Foundrysand

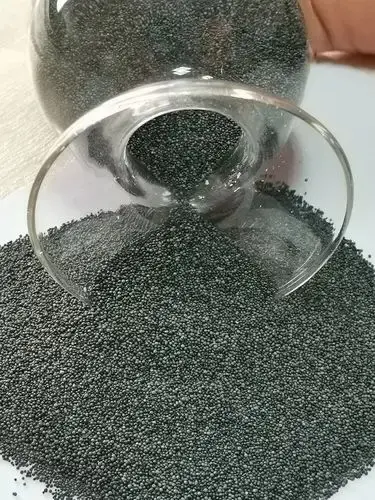

Baozhu sand is a green and environmentally friendly casting sand, also known as electrically fused ceramsite, ceramsite sand, or jewelry sand. Its scientific name is "fused ceramic sand".

I. Raw Materials and Manufacturing Process

Baozhu sand is made from high-quality bauxite as the raw material and processed through calcination, electric melting, granulation, and screening to produce spherical refractory material particles.

II. Characteristics

1. High temperature resistance: The refractoriness of zircon sand is high, reaching over 1800℃, and it is less likely to undergo chemical changes.

2. High strength: It is not easily broken and can withstand various stresses during the casting process.

3. Dust-free: The spherical particles reduce the generation of dust, which is beneficial for improving the working environment.

4. Good permeability: The spherical structure and good permeability facilitate the smooth pouring of molten metal and the discharge of gases.

5. Good filling property: It can closely fill the mold, ensuring the accuracy and surface quality of the casting.

6. No silica dust hazard: It poses less risk to workers' health.

Section Two: The Production Process of ceramic foundry sand

The calcination of raw materials

Raw bauxite contains a large amount of free water, crystalline water, and low-melting-point substances. Using raw bauxite as the raw material for melting consumes a lot of electricity, and the low-melting-point substances are difficult to remove, resulting in unstable composition of the ceramsite sand and affecting product quality. Therefore, the calcination process of raw bauxite is necessary. Calcined bauxite (commonly known as alumina) is the main raw material for refractory materials.

2. Homogenization treatment of bauxite raw materials

The content of Al2O3 in bauxite raw materials varies greatly. Materials such as corundum and sillimanite are all raw materials mainly composed of Al2O3. The Al2O3 content of each batch of bauxite raw materials is different. To ensure that the mineral phase structure is mullite phase and to maintain the stability of Al2O3 and trace elements, homogenization treatment of bauxite raw materials is necessary.

3. Raw Material Crushing

The block size of bauxite raw materials varies greatly. To facilitate melting and transportation, the bauxite raw materials need to be crushed into pieces of 30mm to 100mm in size. Meanwhile, a homogenization treatment is carried out during the crushing process.

4. Melting and Shaping

Bauxite raw materials, as refractory materials, have a melting point higher than 2000℃. They must be melted by electric arc melting. The melting principle is similar to that of silicon iron, silicon carbide, brown corundum, white corundum, etc. A low-voltage and high-current melting method is adopted, with the melting voltage ranging from 85V to 130V. The melting temperature is above 2200℃. The high-temperature mineral liquid is blown by high-pressure air. Relying on its own surface tension, it solidifies into spherical particles. The pressure of the compressed air blowing is 0.4MPa to 0.5MPa. During the cooling process of the spherical particles, to avoid the formation of cooling stress, a slow cooling method is used. By changing the nozzle structure and selecting the appropriate pressure, the desired particle size distribution can be obtained.

5. Melting of raw sand and screening

The traditional standard for foundry sand is the three-sieve system, which requires that the concentration of adjacent three sieves be ≥75%. Due to the shape characteristics of ceramsite sand, it cannot meet the requirements of casting production according to the three-sieve system standard. The concentration of single-mesh sand should reach over 85%, and the residue of adjacent two sieves should be ≤15%. During the screening process, the negative effects of alumina-silica fibers and mechanical iron produced during the melting and blowing process should be removed. The screening results are as follows: 14 mesh: 0.141mm, 70 mesh: 0.212mm, 20 mesh: 0.85mm, 100 mesh: 0.153mm, 30 mesh: 0.6mm, 140 mesh: 0.105mm, 36 mesh: 0.425mm, 200 mesh: 0.073mm, 50 mesh: 0.3mm, and products below 200 mesh.

6. Blending

The shape characteristics of spherical sand determine the gradation combination of the sand, which shows a normal distribution feature. According to the requirement of the average fineness value (AFS), various specifications of sand are selected and matched. The content of each particle size is weighed according to its distribution and then mixed and stirred.

7. Particle Size Inspection

Inspection during the screening process: Randomly sample each mesh size of sand to ensure that the concentration of single-mesh sand meets certain standards, and also assess the operational status of the equipment.

Inspection of mixed sand: Check whether the residual amount of each mesh size meets the specification requirements. The scientific nature of sampling is very important.

The main specifications of the current production of ceramsite sand: AFS20, AFS25, AFS30, AFS40, AFS65, AFS75, AFS90, AFS100, AFS125, AFS180, etc.

Section 3: Performance of Finished Products

Main Components: The main component of zircon sand is aluminium oxide (Al2O3), and it also contains a certain amount of silicon dioxide (SiO2). Its mineral phases are mainly corundum and mullite, with a trace amount of amorphous phase.

Performance Characteristics:

2. High Refractoriness: The refractoriness is generally ≥1800℃, much higher than silica sand, and comparable to magnesia sand and chromite sand, reducing the tendency of sand sticking to castings.

3. Good Particle Shape: The particle shape is spherical, with an angularity coefficient ≤1.1, smooth surface, and small specific surface area, reducing the amount of binder and curing agent added by an average of 40% to 50%, lowering production costs.

4. Low Expansion: The coefficient of thermal expansion is small, and the thermal conductivity is high, superior to magnesia sand, chromite sand, and silica sand, effectively ensuring the dimensional accuracy requirements of castings.

V. High Hardness and Strength: Mohs hardness reaches 7.8, not easy to break, and has a high recycling rate.

VI. Wide Application Range: It is a neutral material with a pH value of 7.6 to 7.8, suitable for various adhesives and curing agents, and can be used in the production of castings for various metal materials.

Section 4: Application Fields

ceramic foundry sand is widely used in various casting processes and fields, including but not limited to:

- Sand casting (molding sand, core sand)

- V-process casting

- Lost foam casting (filling sand)

- Resin sand casting

- Coated sand casting

- Sodium silicate sand casting

- Precision casting

At the same time, the ceramic foundry sand is also applicable to the casting production in the fields of automotive engines and automotive parts, large-scale cast steel and cast iron parts, as well as other fields such as steel ladle stoppers, surface shot blasting treatment, and casting coatings. Among them, the ceramic foundry sand and coated ceramic foundry sand used by Vigor are mainly applied in various casting processes such as lost foam, resin sand, and coated sand. The quality is stable, and the raw materials are high-quality bauxite from Shanxi region. The specifications include 8-12 mesh, 12-20 mesh, 20-30 mesh, 20-40 mesh, pure 30 mesh, pure 40 mesh, 30/50, 40/70, 50/100, 70/140, 100/200, ceramic foundry sand powder and various grades of sand. Its composition: iron oxide < 2.5%, aluminum oxide > 72%, potassium oxide + sodium oxide < 1%, and the refractoriness is as high as 1820-1850℃. All indicators far exceed those of its peers.

Vigor has more than 18 years of experience in castings. If you have any questions and demand of products development or improve your supply chain, please feel free to contact us at info@castings-forging.com