Knowledge

Application of Femtosecond Laser in Bearings and Shafts: Surface Micro-texturing, Lubrication and Wear Resistance Characteristics

In industrial production, metal components will rub against each other during contact, especially in high-speed or high-frequency sliding and rotating movements, which can easily cause wear due to friction and eventually lead to product scrapping.

For instance, during the operation of bearings, friction and wear affect the stability and reliability of the entire system and the service life of the products. Therefore, how to improve the surface friction performance of such products and enhance the reliability of bearing products is an important research direction.

Research and actual production test data show that forming micro-textures through surface modification can significantly improve the wear resistance of the friction surface, thereby enhancing the stability of the product itself.

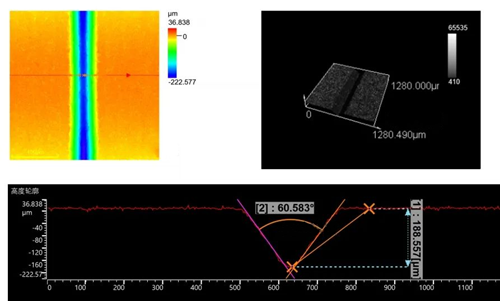

Precision V-shaped groove etching on the material surface --------------------------

What is surface micro-texturing?

Surface micro-texturing refers to the formation of specific shapes, sizes and distribution patterns of micro-structures on the material surface, such as blind holes, blind grooves, and micro-protrusions.

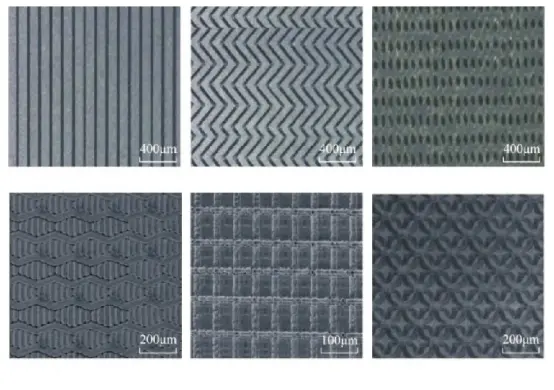

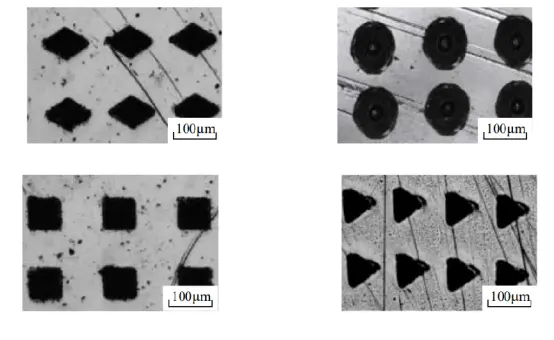

At present, the design and application of micro-textures mainly focus on circular micro-pits and V-shaped grooves. Special types include square pits, triangular pits, rhombic pits, etc. The dimensions typically range from a few micrometers to several hundred micrometers.

(Shapes of different micro-textures) ---------------------------------------

The application of surface micro-texturing?

Surface micro-texturing has currently been applied in many fields, such as:

Applying the surface micro-texturing technology to the sealing ring and processing circular micro-pits on it can enhance the sealing effect and load-bearing capacity of the sealing ring accordingly.

By processing circular micro-textures of appropriate density on the inner wall of the engine piston cylinder, a reduction of over 40% in frictional loss was achieved.

3. By machining micro-textures of different shapes on thrust bearings, the load-carrying capacity of thrust bearings has been significantly enhanced.

(V-shaped groove etching on the surface of CT tube bearing) --------------------------

At present, with the development of China's high-end manufacturing industry, the application scope of micro-texturing on material surfaces is becoming increasingly wide, and it is showing a trend of smaller scale and higher precision. This poses a challenge to the manufacturing technology of micro-texturing.

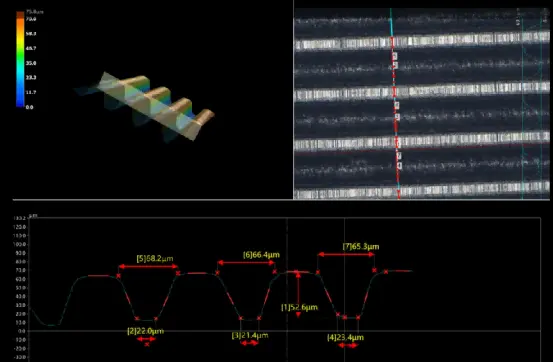

(U-shaped groove etching) ------------------------------------------------------------

What are the processing techniques for surface micro-texturing?

At present, the main methods for processing surface micro-textures include laser processing, electrical discharge machining, electrochemical machining, cold forming, focused ion beam processing, plasma etching, and ultra-precision turning.

Compared with other technologies, femtosecond laser has the advantages of high processing accuracy, small thermal influence, small processable size, high repeatability, good controllability, high flexibility, no stress effect, and no pollution. It is a relatively suitable advanced technology for completing the processing of micro and nano-scale surface micro-textures at present.

This is because the femtosecond laser has an extremely short pulse width and an extremely high peak power, making it the best in terms of processing quality and effect among industrialized pulsed lasers.

Femtosecond is a concept of time. Femtosecond laser refers to the single pulse time of the laser being one quadrillionth of a second, that is, 10-15 seconds. Through a femtosecond laser, a certain amount of energy is output within such a short period of time, and its peak power is extremely high. Therefore, in theory, femtosecond laser can process any material and produce a very small heat-affected zone.

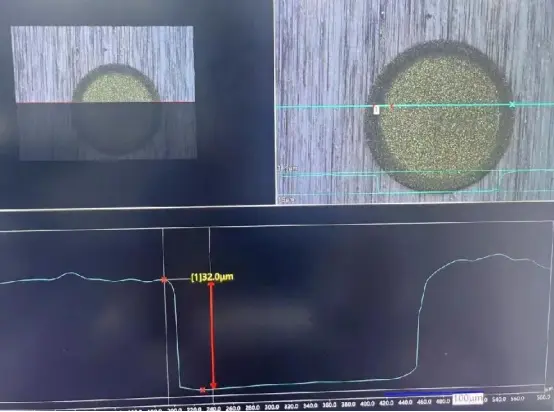

Blind hole etching --------------------------

4 Conclusion

With the development of high-end manufacturing, surface micro-texturing will have broad application prospects and bring high application value to precision parts such as bearings. At the same time, we believe that femtosecond lasers, with their advantages of no material restrictions, minimal thermal influence, and extremely high processing accuracy, will surely contribute to the rapid development of related industries.