To optimize the melting process of ductile iron and reduce gas holes, the following aspects can be considered:

2025-04-08 18:29:09

The aluminum alloy grades suitable for die casting and their applications are as follows

2025-04-02 16:52:21

During operation, the failure forms of the springs or metal bellows in mechanical seals include permanent deformation, fracture, corrosion, creep or relaxation, etc. Among them, the influencing factors of permanent deformation and fracture failure of metal bellows are the most complex. The loading elastic elements of mechanical seals are mostly cylindrical compression helical springs. Therefore, this section mainly analyzes the failure of cylindrical compression helical springs, and the principle also applies to other springs or metal bellows.

2025-03-31 18:00:01

Chemical and electrochemical corrosion pose a serious threat to the service life of mechanical seals. The causes of corrosion are complex and varied. Here, only the most common forms of corrosion in mechanical seals and the most significant influencing factors are analyzed.

2025-03-31 17:58:50

Through the analysis of failure causes, the technical level of applying mechanical seals can be improved. Structural design improvements are largely derived from fault analysis. To achieve as accurate an analysis of faults as possible, it may sometimes take time and even require the use of specialized testing techniques.

2025-03-31 17:56:57

To reduce the porosity of ductile iron through mold design, the following aspects can be considered and optimized

2025-03-27 18:01:59

The production of cast steel parts used to commonly employ water glass self-hardening sand, furan resin self-hardening sand and alkaline phenolic resin self-hardening sand for molding and core making.

2025-03-27 17:58:07

Heat treatment is a crucial step in ensuring the mechanical properties of cast steel parts. Through forming, pouring, shakeout and cleaning, the casting takes its final shape - but it may not be strong or flexible enough for final use. By heating and cooling the metal at different rates, foundries can alter its mechanical properties. But how does the application of heat change the strength or flexibility of the metal?

2025-03-27 17:56:33

Surface treatment is a process method that artificially forms a surface layer with mechanical, physical and chemical properties different from those of the base material on the surface of the base material. The purpose of surface treatment is to meet the requirements of corrosion resistance, wear resistance, decoration or other special functions of the product. For metal castings, the surface treatment methods we commonly use are mechanical grinding, chemical treatment, surface heat treatment, and surface spraying, etc.

2025-03-27 17:55:28

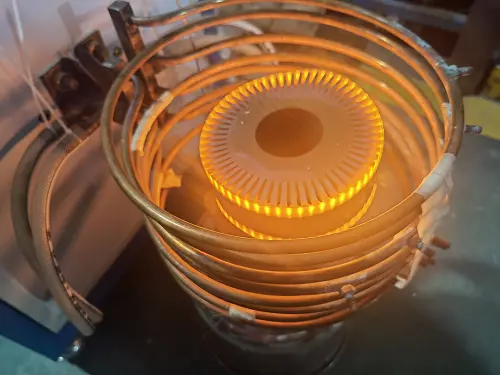

The influence of high-frequency quenching on the internal structure of metals is multi-faceted, specifically manifested in the following aspects:

2025-03-27 17:53:51

To reduce and eliminate the impact of high-frequency quenching on the internal structure of metals, the following aspects can be considered:

2025-03-27 17:52:11

The commonly used materials in die-casting processes mainly include non-ferrous metals such as aluminum, zinc, magnesium, and copper, as well as their alloys. These materials hold significant importance in the die-casting field due to their unique physical and chemical properties.

2025-03-26 13:24:55

367