Knowledge

How to Reduce and Eliminate the Influence of High-frequency Quenching on the Grains and Microstructure of metals

To reduce and eliminate the impact of high-frequency quenching on the internal structure of metals, the following aspects can be considered:

I. Optimization of Quenching Process Parameters

Precise control of heating temperature: Utilize high-precision temperature sensors and advanced control systems to ensure that the heating temperature of the workpiece during the quenching process is not only uniform but also moderate. Through real-time monitoring and adjustment, overheating and overburning of the workpiece can be avoided, thereby effectively reducing the risk of abnormal grain growth and changes in microstructure. The accuracy of temperature control directly affects the quenching quality, so the adoption of advanced temperature control technology is the key to improving the quenching effect.

Reasonable control of heating time: Set the heating time scientifically and reasonably based on the material, size of the workpiece, and specific quenching requirements. Ensure that heat can be fully and evenly transferred to every part of the workpiece, while avoiding surface overheating due to excessive heating time. Reasonable heating time not only guarantees the quenching effect but also effectively prevents the deterioration of the internal microstructure of the metal.

Selection of appropriate cooling methods and media: Carefully select the appropriate quenching medium based on the material properties and geometric shape of the workpiece, such as water-soluble quenching fluid, oil, or other specialized cooling media. By controlling the cooling rate, the uniformity of the quenching layer depth and hardness can be ensured. Additionally, regular inspection and replacement of aging quenching media to maintain their stable and effective cooling performance is also an important measure to reduce the impact on the internal microstructure of the metal.

II. Optimization of Workpiece Design

Design the areas prone to cracking as circular or with chamfering: During the workpiece design stage, fully consider the issue of stress concentration. Design the areas prone to cracking as circular or apply appropriate chamfering to effectively reduce stress concentration and thereby lower the risk of cracking during quenching.

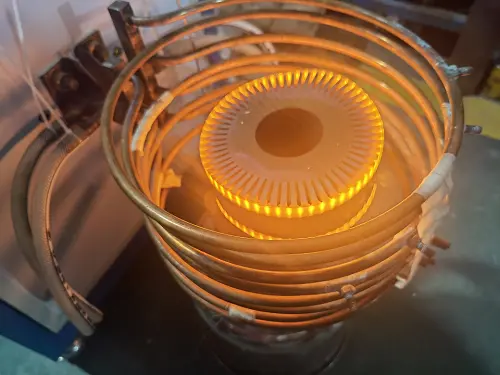

Reasonable design of inductors: According to the shape of the workpiece and heating requirements, carefully design the structure and layout of the inductors to ensure uniform heating and avoid local overheating. The design of inductors directly affects the heating effect. A reasonable inductor design can effectively reduce the inhomogeneity of the metal's internal structure.

III. Strengthening Post-Quenching Treatment

Timely tempering: After quenching is completed, tempering treatment should be carried out promptly to eliminate residual stress generated inside the workpiece and stabilize the metal structure. Tempering treatment not only prevents overheating and overburning but also significantly enhances the toughness and service life of the workpiece, ensuring its stable performance in practical applications.

Surface strengthening treatment: After quenching, surface strengthening treatments such as carburizing and nitriding should be performed on the workpiece to further increase the hardness and wear resistance of the surface. Surface strengthening treatment not only improves the surface properties of the workpiece but also reduces to a certain extent the adverse effects of quenching on the internal structure of the metal.

IV. Strengthening Equipment Maintenance and Management

Regular inspection and maintenance of high-frequency quenching equipment: Establish a complete equipment maintenance system, conduct comprehensive inspections and maintenance of high-frequency quenching equipment on a regular basis to ensure that the equipment is always in good working condition. The stable operation of the equipment is the foundation for ensuring quenching quality. Any equipment failure may lead to quenching quality issues.

Strengthening equipment safety management: Formulate and strictly enforce strict safety management systems to ensure the safe operation of equipment under specified conditions. By enhancing the training and management of operators, prevent equipment failures caused by improper operation or environmental factors, thereby ensuring the stability and reliability of the quenching process.

In conclusion, through a comprehensive set of measures including optimizing quenching process parameters, improving workpiece design, enhancing post-quenching treatment, and strengthening equipment maintenance and management, the impact of high-frequency quenching on the internal structure of metals can be effectively reduced and eliminated. This significantly improves the performance and quality of the workpieces, ensuring their stability and reliability in practical applications.

Vigor has more than 18 years experience on heat treatment of castings, forgings and other metal parts. If you have any question and demand of products development or improve your supply chain, please feel free to contact us at info@castings-forging.com