Knowledge

Will Passivation of Stainless Steel Castings Affect Conductivity?

Stainless steel passivation treatment enhances corrosion resistance by forming a dense oxide film on the surface (such as Cr₂O₃). The impact of this treatment on electrical conductivity needs to be systematically analyzed from three dimensions: material properties, film structure, and process parameters.

I. The semiconductor characteristics of the passivation film dominate the conductive behavior

The passivation film is essentially a semiconductor, and its conductivity depends on the carrier density and band structure. Taking the passivation film formed on 304 stainless steel in sulfuric acid solution as an example, the film layer shows p-type semiconductor characteristics when the scanning potential is lower than 0VSCE in a 5‰ H₂SO₄ solution, and turns to n-type semiconductor when the potential is higher than 0VSCE. The carrier concentration (N) of the film layer is directly related to the defect density - the higher the N value, the stronger the conductivity of the film layer, but the uniform corrosion resistance decreases; conversely, a lower N value weakens the conductivity but enhances the corrosion resistance. This "conductivity-corrosion resistance" trade-off relationship needs to be carefully considered in scenarios such as electronic devices and medical equipment. For example, in electronic connectors that require high conductivity, the performance can be balanced by optimizing the passivation process (such as controlling acid concentration and film formation potential) or using composite coatings (such as PVD-DLC).

II. Process parameters and material types have significant influences

Different process parameters have obvious differences in their impact on the conductivity of the film layer. In sulfuric acid solution, the electrical conductivity of the film layer decreases with the increase of sulfuric acid concentration and film formation potential - in a 10mol/L sulfuric acid solution, the resistance of the film layer formed at a potential of 500mV can reach 130Ω, and the electrical conductivity drops to 2×10⁻⁶S/cm. Although an increase in film thickness may enhance conductivity due to the tunneling effect, the resistance increases significantly when it exceeds 5nm. In addition, the material type determines the passivation behavior: austenitic stainless steel (such as 316L) has a stronger resistance to pitting corrosion due to the presence of molybdenum, but the conductivity may be slightly lower than that of ferritic stainless steel due to the higher density of the film layer; for duplex steel (such as 2205), the conductivity of the film layer needs to be optimized through orthogonal experiments due to the difference in the two-phase structure.

III. Conductivity Control Strategies in Practical Applications

In the field of electronic devices, the conductivity of passivated stainless steel must meet specific thresholds. For instance, stainless steel requires verification of the film resistance (≥10⁶Ω·cm²) and salt spray corrosion resistance (≥24 hours without rust) through electrochemical impedance spectroscopy (EIS). In medical devices, 316L surgical scissors after passivation need to ensure the metal ion release (e.g., nickel ≤0.2μg/cm²/week) meets biocompatibility standards through copper sulfate titration test (ASTM A380) and electrochemical testing, while maintaining necessary conductivity to avoid static electricity risks.

IV. Testing Methods and Standard Systems

Conductivity assessment should incorporate multiple approaches such as conductivity measurement, four-probe method, and electrochemical impedance spectroscopy. For example, a conductivity meter can quantify the film resistivity; Mott-Schottky analysis can reveal semiconductor characteristics; salt spray tests and electrochemical tests verify corrosion resistance and film integrity. Industry standards such as ASTM A967 and ISO 15675 explicitly require verification of film quality through copper sulfate titration tests after passivation treatment, while ISO 10993-17 stipulates limits on metal ion release.

The impact of passivation treatment on the electrical conductivity of stainless steel is essentially a trade-off between corrosion resistance and electrical conductivity. By adjusting process parameters (such as acid concentration, potential, and temperature), selecting suitable material types, and integrating composite coating technologies, it is possible to enhance corrosion resistance while maintaining electrical conductivity to the greatest extent. In the future, with the development of intelligent passivation processes (such as real-time monitoring by electrochemical sensors) and material innovations (such as the passivation of biodegradable magnesium alloys), this balance will become more precise, meeting the strict requirements for material performance in high-end manufacturing fields.

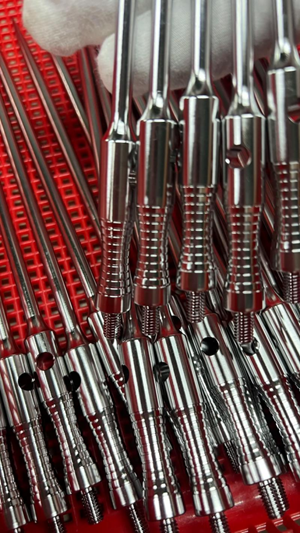

Vigor has more than 20 years experience and the professional team in casting, die-forging and the post treatment processes. If you have any question or products need to do, please feel free to contact us at info@castings-forging.com