Knowledge

Why Is Gas Analysis Necessary for Heat Treatment? What Is The Relationship Between Carbon Potential Control and Gas Analysis Instruments?

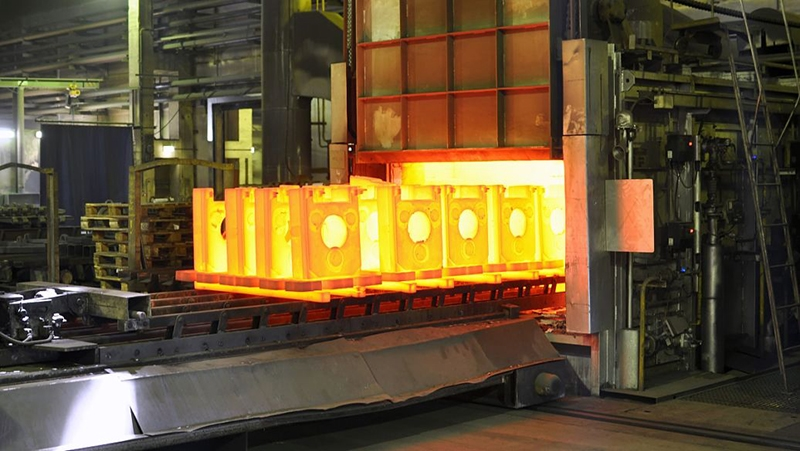

Heat treatment refers to a metal thermal processing technique in which materials are heated, held at a certain temperature, and then cooled while in the solid state to achieve the desired microstructure and properties. Simply put, it involves "four fires": normalizing, annealing, tempering, and quenching. Its functions are as follows:

- Eliminating internal stresses in the raw material. It is often used for castings, forgings, and welded parts.

- Improving processing conditions to make the material easier to work with. For example, annealing and normalizing.

- Enhancing the comprehensive mechanical properties of metal materials. For instance, through quenching and tempering.

- Increasing the hardness of the material. Such as quenching and carburizing quenching.

In summary, heat treatment eliminates various stress defects in raw parts, improves their processability, prepares them for subsequent processing, significantly enhances their mechanical properties, and increases their service performance and lifespan. Therefore, it is an indispensable step in forging.

I. Heat Treatment Furnaces

Due to the diversity of heat treatment processes and the shapes and sizes of heat-treated workpieces, heat treatment furnaces come in various types and structures. There are many classification methods for heat treatment furnaces:

- By the highest temperature: furnaces with a temperature above 1000°C are classified as high-temperature heat treatment furnaces; those with a temperature between 650°C and 1000°C are medium-temperature heat treatment furnaces; and those with a temperature below 650°C are low-temperature heat treatment furnaces.

- By the main heat treatment process: solid solution, quenching, normalizing, tempering, annealing, and carburizing furnaces, among others.

- By the heating source: those using fuel combustion as the heat source include coal-fired furnaces, oil-fired furnaces, and gas-fired furnaces; in addition, there are electric furnaces such as resistance furnaces, electrode furnaces, and induction heating furnaces.

- By the heating medium inside the furnace: those using gas as the heating medium include air, flue gas, controlled atmosphere, and vacuum furnaces; those using liquid as the heating medium include molten salt and molten lead furnaces; and those using solid as the heating medium include fluidized bed furnaces.

II. The Relationship between Heat Treatment and Gas Analysis Monitoring

When it comes to this, it is necessary to mention the control of heat treatment atmosphere. Atmosphere control refers to the use of gases with controllable components during the heating of metals to protect the metal surface and adjust the chemical composition of the metal surface. One of the key development directions of heat treatment production technology is controllable atmosphere heat treatment. Especially for the bright quenching, annealing, carburizing quenching, carbon-nitrogen co-penetration quenching, and gas nitrocarburizing of carbon steel and general alloy structural steel parts, controllable atmosphere remains the main method. Therefore, controllable atmosphere heat treatment is still a major component of advanced heat treatment technology.

The controllable atmospheres mainly include endothermic gas, exothermic gas, nitrogen-based atmosphere, ammonia decomposition gas, injection decomposition gas, hydrogen and charcoal gas.

2.1 Endothermic gas

In the generator, natural gas, liquefied petroleum gas and other gases are mixed with a certain proportion of air (when the air volume is small, the mixed gas is partially combusted first), and then passed through a catalyst heated to a high temperature (above 1000℃), causing the unburned part of the mixed gas to undergo thermal cracking (endothermic reaction) and thus produced. Endothermic gas is a widely used controllable atmosphere. When used as a carrier gas, an appropriate amount of enriched gas (methane or propane) can be introduced into the heating furnace to carburize the surface of low-carbon steel parts, making the carbon content reach the specified requirements. By controlling the addition amount of enriched gas, the carbon potential of the furnace gas can be controlled.

2.2 Exothermic gas

In the generator, natural gas, liquefied petroleum gas and other gaseous fuels or alcohol, diesel and other liquid fuels are mixed with a large amount of air to approach complete combustion (exothermic reaction), and then the combustion products are preliminarily purified (removing water) or highly purified (removing water, carbon dioxide and carbon monoxide) to obtain the gas. Exothermic gas can be used for bright annealing of low-carbon steel, decarburizing annealing of silicon steel sheets, bright quenching of medium-carbon and high-carbon steel, sintering of powder metallurgy, and gas nitrocarburizing, etc. Purified exothermic atmosphere can also be used for annealing and brazing protection of stainless steel, or as a carrier gas for carburizing, etc.

2.3 Nitrogen-based atmosphere

The commonly used one is high-purity nitrogen gas obtained by purifying industrial nitrogen produced in the oxygen-making process (removing oxygen or air), or it can be the gas obtained by evaporating liquid nitrogen. Nitrogen-based atmosphere can be used for heating protection, and by adding methanol, etc., its composition can be made similar to endothermic gas and used as a carrier gas for carburizing. By adding enriched gas (such as propane, etc.), carburizing can be achieved. Its advantage is that it can save natural gas, liquefied petroleum gas, etc., and the carbon potential can also be controlled.

2.4 Ammonia decomposition gas

Ammonia can be completely decomposed into 3 volumes of hydrogen and 1 volume of nitrogen at a certain temperature and with the action of a catalyst, forming ammonia decomposition gas. It can also be partially combusted by mixing ammonia with air, and then water is removed for purification to obtain ammonia combustion gas (mainly composed of nitrogen). Both of these atmospheres contain hydrogen and belong to hydrogen-water type mixed gases. They are mostly used for heat treatment of stainless steel and high-speed steel, and sintering of powder metallurgy. Because ammonia is relatively expensive, the preparation cost is relatively high.

2.5 Drip decomposition gas

The decomposition gas produced by controlled carburizing with a drip method also belongs to a controllable atmosphere. This is the Cabomag method proposed in the early 1960s. The principle is: two organic liquids are dripped into the furnace, where they undergo thermal cracking. One liquid (such as methanol) is used as the carrier gas, and the other (such as ethyl acetate) is used as the enriched gas to achieve carburizing of steel, and the carbon potential of the furnace gas is controlled by adjusting the dripping rate of the second liquid. The advantage of this method is that it does not require a gas generator, the equipment structure is simple, and it is suitable for batch production. Hydrogen is a reducing gas. Absolutely dry hydrogen is difficult to prepare, so the hydrogen used is actually a mixture of trace water and hydrogen. Whether metal is oxidized or reduced when heated in hydrogen depends on the ratio of water to hydrogen. However, hydrogen protection heating cannot completely prevent decarburization of steel. Annealing of stainless steel and silicon steel sheets, sintering of powder metallurgy, and reduction of iron powder can all be carried out in hydrogen.

2.6 Charcoal Gas

Charcoal gas is the gas produced when air is blown into a generator by a blower and reacts with hot charcoal. Its main components are carbon monoxide and carbon dioxide. Carbon monoxide is a reducing gas, while carbon dioxide is an oxidizing gas. When steel is heated in this mixed gas, the oxidizing and reducing capabilities of the atmosphere depend on the CO2/CO ratio. By adjusting this ratio, the steel can be heated without oxidation or decarburization. Charcoal gas can be used for protective heating of steel.

III. Practical Application of Gas Analysis Monitoring System in Heat Treatment

The carbon potential of furnace gas refers to the carbon content when the furnace gas is in equilibrium with the carbon content in the austenite on the steel surface at a certain temperature. It can be simply understood as an indicator of the carburizing ability of the furnace gas; it is related to the composition of the furnace gas and temperature, and its level reflects the strength of the carburizing ability of the furnace gas. The carburizing ability (carbon potential) of carburizing gas is determined by the proportion of its gas components (such as carbon monoxide, carbon dioxide, water vapor, oxygen, etc.).

No matter what kind of heat treatment atmosphere control is used, there is a very strict control over the concentration of gas components. Usually, the content of a certain component (such as water vapor, carbon dioxide, or oxygen) is measured to provide a signal to the control system, which promptly adjusts the gas composition to change the carbon potential in the furnace.

The NK-500 series infrared gas analysis system of Nuoke Instruments can be modularly customized according to the characteristics of the atmosphere to be measured and the process requirements of enterprises. It can simultaneously, continuously and online detect the atmosphere of each path in one system, solving the drawbacks of traditional measurement. It can monitor the real gas component concentrations (such as CO, CO2, CH4), oxygen potential, carbon potential, etc. in various heat treatment furnaces in real time. It is a powerful assistant for on-site engineers to analyze the furnace gas composition, troubleshoot and optimize the process.

Vigor has more than 20 years experience and the professional team in castings and forging as well as the post of treatment processes. If you have any question or products need to do, please feel free to contact us at info@castings-forging.com