Knowledge

The yield strength has increased by over 10%, and the elongation has exceeded 21%! The addition of trace calcium makes the ultra-light magnesium-lithium alloy stronger and more ductile.

Ultra-light magnesium-lithium alloy is an ideal material for aerospace and electronic equipment, but its low strength and unstable performance have always restricted its application. The latest research has found that by precisely adding a trace amount of calcium, the strength and plasticity of magnesium-lithium alloy can be simultaneously enhanced, with the yield strength increasing by over 10% and the elongation exceeding 21%!

Magnesium-lithium alloy, as the lightest metallic structural material, has a density of only 1.35–1.65 g/cm³, which is lighter than common magnesium alloys. It features extremely high specific strength and stiffness, as well as excellent damping and electromagnetic shielding properties, making it an ideal choice for lightweight applications in aerospace, rail transportation, and 3C electronic products. However, magnesium-lithium alloys suffer from low absolute strength, poor heat resistance, and subpar corrosion resistance, which severely restrict their engineering applications.

Alloying is an effective way to improve the performance of magnesium-lithium alloys. Aluminum (Al) can significantly strengthen magnesium alloys, but it tends to form the unstable MgLi₂Al phase, leading to unstable microstructure and properties. Calcium (Ca) can refine grains and form strengthening phases, while zirconium (Zr) and scandium (Sc) also have the ability to refine grains and promote precipitation. Nevertheless, how to synergistically control the microstructure and mechanical properties of magnesium-lithium alloys through multi-element microalloying remains a current research hotspot and challenge.

The Mg-5Li-1Al-xCa-0.25Zr-0.01Sc (x=0, 0.25, 0.5) alloys were prepared by common gravity casting. The microstructure was analyzed by optical microscope, scanning electron microscope, energy dispersive spectrometer and transmission electron microscope. The mechanical properties were evaluated by room temperature tensile test. The influence of Ca content on the microstructure and properties of the alloys was systematically investigated.

Microstructure: Ca regulates the morphology and distribution of precipitated phases

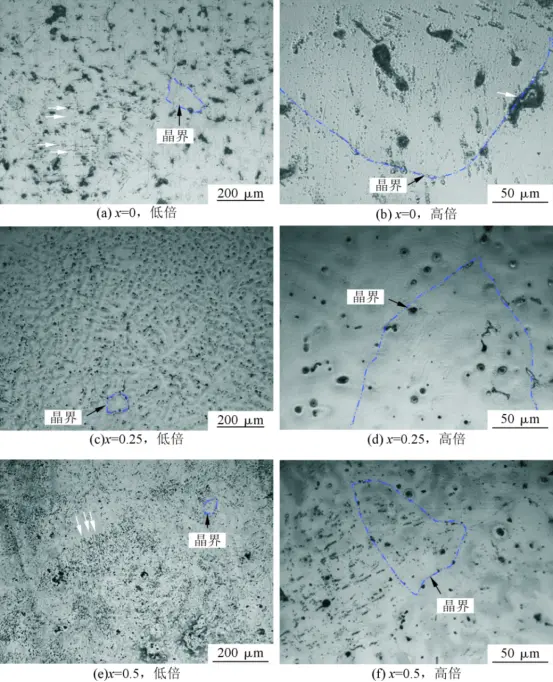

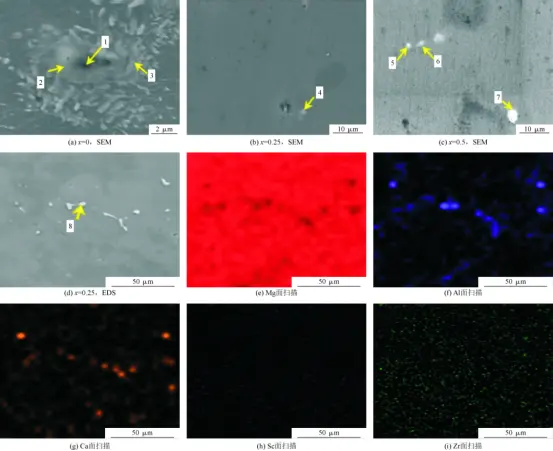

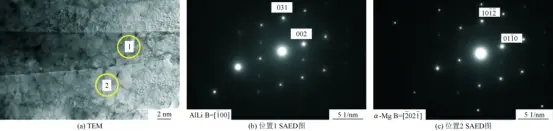

Without the addition of Ca, a large number of discontinuous eutectic clusters of AlLi and intragranular discrete precipitated phases form in the alloy. After adding 0.25% Ca, the AlLi particles dissolve, forming uniform solute clusters and core-shell structured spherical particles [with Al₃(Sc,Zr) as the core and AlLi as the shell], while fine (Mg,Al)₂Ca particles are generated, significantly refining the grains. However, when 0.5% Ca is added, high-density, parallel-arranged needle-like continuous precipitated phases of AlLi appear within the grains, which can easily lead to coplanar slip during deformation and is not conducive to plasticity.

Figure 1 OM image of Mg-5Li-1Al-xCa-0.25Zr-0.01Sc alloy ----------------------------------

SEM images and EDS analysis of 23 kinds of alloys in Figure 2 ----------------------------

Figure 3 TEM image and corresponding SAED pattern of Mg-5Li-1Al-0.5Ca-0.25Zr-0.01Sc alloy -----------------------

2. Mechanical properties: 0.25% Ca achieves a synergistic improvement in strength and plasticity

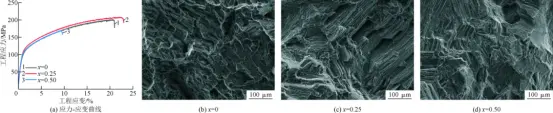

The alloy with 0.25% Ca addition exhibits the best comprehensive mechanical properties: yield strength of 99.2 MPa, tensile strength of 210.4 MPa, and elongation of 21%, which are respectively 10.7%, 4.9%, and 10.5% higher than those of the alloy without Ca addition. However, the alloy with 0.5% Ca addition shows a significant decrease in plasticity and strength due to the planar slip caused by the needle-like AlLi phase. All alloys display serrated flow characteristics (PLC effect), which is attributed to the pinning effect of solute atoms on dislocations.

Figure 4 Tensile stress-strain curves and fracture morphologies of Mg-5Li-1Al-xCa-0.25Zr-0.01Sc alloys (x = 0, 0.25, 0.50, mass fraction %) ---------------------------------

【Main Conclusions】

The addition of trace Zr/Sc can induce the formation of AlLi precipitates in Mg-5Li-1Al alloy;

The addition of 0.25% Ca can refine the grains, promote the re-dissolution and uniform precipitation of AlLi, and form core-shell structured particles and (Mg,Al)₂Ca phase;

The addition of 0.5% Ca leads to the high-density needle-like AlLi phase precipitation, causing co-planar slip and reducing plasticity;

The alloy with 0.25% Ca addition has the best comprehensive mechanical properties, with simultaneous improvement in strength and plasticity.