Knowledge

The Influence of Solution treatment cooling process on the microstructure and properties of cast super duplex stainless steel CD3MWN

Introduction: The effects of different solution treatment cooling processes (direct water quenching and furnace cooling followed by water quenching) on the microstructure and properties of the super-duplex stainless steel CD3MWN were investigated. The results show that under the direct water quenching solution cooling process, when the super-duplex stainless steel CD3MWN is heat-treated below 1120 °C, the amount of σ phase precipitates increases with the decrease of temperature, and the material has high strength and hardness; when heat-treated at 1120 °C and above, the σ phase is completely dissolved, and the ratio of α and γ phases is the decisive factor affecting the properties of CD3MWN steel. Compared with direct water quenching, under the solution cooling process of furnace cooling followed by water quenching, no σ phase precipitates in the microstructure, and it is a two-phase structure of α and γ phases, with the ratio of the two phases approaching 1:1, and has better comprehensive properties. In the production process of CD3MWN castings, the solution cooling process of furnace cooling followed by water quenching should be preferred, which can not only ensure a better match of strength and plasticity, but also reduce the risks brought by high-temperature water quenching to the castings. Duplex stainless steel is composed of austenite and ferrite phases, with excellent comprehensive properties, and is widely used in environments with chloride ions, marine engineering, petrochemical and natural gas, shipbuilding, papermaking, power and other industries. The development of duplex stainless steel has gone through three generations. Since the development of the third-generation super-duplex stainless steel, due to their excellent mechanical properties and high corrosion resistance, as well as cost advantages compared with super-austenitic stainless steel and nickel-based alloys with similar properties, their industrial applications in related fields have grown rapidly. CD3MWN is a cast super-duplex stainless steel first proposed in the American ASTM A890/A890M-12 standard, belonging to the fourth generation of duplex stainless steel, with a pitting resistance equivalent number (PREN) of ≥45. Compared with the third-generation duplex stainless steel, CD3MWN has higher Cr, Mo and N contents, and its microstructure and properties are more sensitive to heat treatment processes. Improper heat treatment processes can cause a significant decrease in the plasticity and corrosion resistance of the material, affecting its normal use. The standard stipulates that the heat treatment temperature should not be lower than 1130 °C, and then furnace-cooled to a temperature not lower than 1060 °C followed by rapid cooling. Currently, many scholars have studied the effects of different solution temperatures on the microstructure and properties of CD3MWN, but there are few studies on the cooling process specified in the standard, which is furnace cooling after solution treatment followed by rapid cooling, and its influence on the microstructure and properties of CD3MWN has not been paid attention to. This study will explore the influence of different furnace cooling temperatures on the microstructure and mechanical properties of super-duplex stainless steel CD3MWN after holding at 1140 °C, aiming to grasp the variation laws of its microstructure and properties, and provide certain guidance for the research and production of super-duplex stainless steel.

1. Experimental Materials and Methods

1.1 Experimental Materials

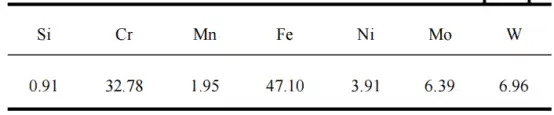

The ASTM A890/A890M CD3MWN super duplex stainless steel was selected as the experimental material. Pure iron, metallic chromium, ferro-chromium nitride, electrolytic nickel, molybdenum rods, tungsten rods, electrolytic manganese, ferro-boron, lanthanum-cerium alloy, and silicon-barium alloy were used as raw materials. The materials were melted in a medium-frequency induction furnace and then cast into 260 mm × 170 mm × 40 mm single-girder test blocks. According to the requirements of various tests, samples of corresponding sizes were prepared in the central area by wire cutting. The samples were heat-treated in a resistance-type heat treatment furnace and then subjected to various tests such as chemical, metallographic, and mechanical property tests. The chemical composition of the test blocks was analyzed using a QSN750-II optical emission spectrometer and a TCH600 gas analyzer. The results are shown in Table 1.

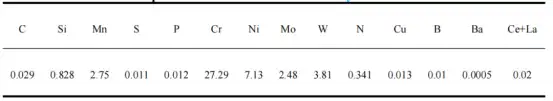

Table 1 Chemical Composition of CD3MWN Alloy in the Test Steel

1.2 Test Methods

The test steel CD3MWN was held at 1140 ℃, 1120 ℃, 1100 ℃, 1080 ℃ and 1060 ℃ for 2 hours respectively and then quenched in water. Another group was held at 1140 ℃ for 2 hours and then furnace cooled to 1120 ℃, 1100 ℃, 1080 ℃ and 1060 ℃ respectively before quenching in water. The microstructure was observed using a ZEISS Observer.Z1m metallographic microscope after etching with a sodium metabisulfite hydrochloric acid solution. According to the provisions of GB/T 13305—2008 "Metallographic Method for Determining the Area Content of α Phase in Stainless Steel", the metallographic images were processed using OLYCIA M3 LEXT image processing software. Ten fields of view were selected at each temperature and the average value was taken to measure the ferrite content and precipitated phase content. The morphology of the precipitated phase and the electron diffraction spots were observed using a JEM-2100 transmission electron microscope, and the composition of the precipitated phase was analyzed using a Genesis X-ray energy dispersive spectrometer. The yield strength and tensile strength were tested using a SINTECH20/G 100 kN material testing machine with a sample size of Φ16 mm×100 mm, with the middle part being Φ8.75 mm×60 mm. The Brinell hardness of the samples was tested using an HB-3000B Brinell hardness tester with a sample size of 20 mm×10 mm×10 mm. The impact toughness of the test steel was determined using a ZBC 2302-C pendulum impact testing machine with a sample size of 55 mm×10 mm×10 mm and a V-shaped notch. The morphology of the impact fracture surface was observed using a Quanta 650 scanning electron microscope.

2. Test Results and Analysis

2.1 Effects of Solution Treatment Cooling Process on Microstructure of CD3MWN Steel

Like the previous three generations of duplex stainless steels, the super duplex stainless steel CD3MWN has the α/γ phase ratio mainly determined by the chemical composition and heat treatment temperature, with the chemical composition playing a dominant role and the heat treatment temperature an auxiliary regulatory role. With the chemical composition of the test steel being constant, the heat treatment plays a key role in regulating the phase ratio. According to the standard ASTM A890/A890M, the heat treatment temperature of CD3MWN steel should not be lower than 1130 ℃, and it should be furnace cooled to no less than 1060 ℃ before rapid cooling. Therefore, it is of great significance to explore the influence law of different furnace cooling temperatures on the microstructure of CD3MWN steel.

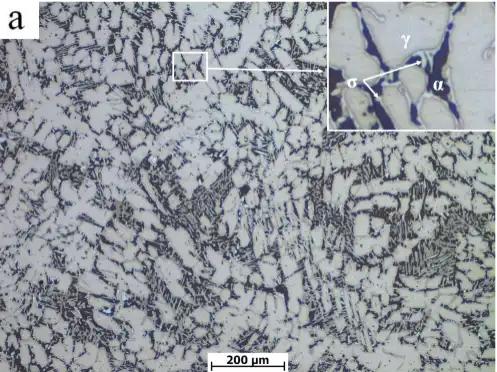

2.1.1 Direct water quenching

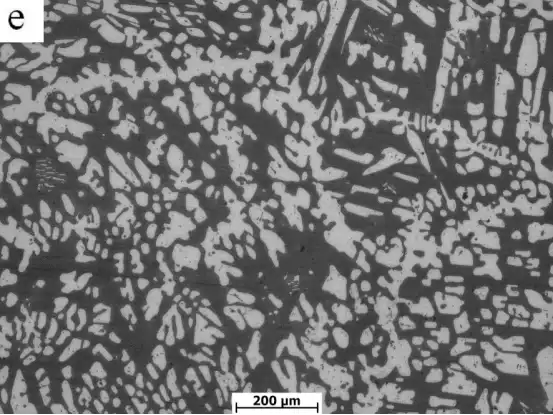

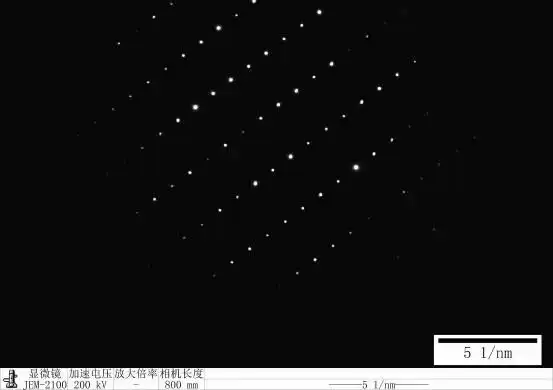

Figures 1(a)-(e) show the microstructures after direct water quenching at different temperatures for 2 hours. The dark areas represent the α phase, the light gray areas represent the γ phase, and there are bright white precipitates around the γ phase boundaries. It can be seen from Fig. 1 that the austenite is distributed in long strips on the ferrite matrix. As the heat treatment temperature increases, the aspect ratio of the austenite continuously decreases, and the amount of austenite phase decreases and gradually spheroidizes. From Figs. 1(a) and 1(b), it can be seen that after heat treatment at 1060 °C and 1080 °C, there are a large number of undissolved bright white precipitates in the microstructure. There are also a few bright white precipitates in Fig. 1(c). To clarify the structure and type of the precipitates, transmission electron microscopy analysis was performed on the samples, and the morphology and electron diffraction patterns are shown in Figs. 2 and 3. The precipitates have a tetragonal structure and are located at the phase boundaries between ferrite and austenite. The energy spectrum results in Table 2 show that the precipitates are enriched with ferrite-forming elements Cr and Mo. This precipitate is a Cr and Mo-rich precipitate, and its precipitation behavior conforms to the precipitation law of the σ phase. Therefore, it is determined that the precipitate is the σ phase.

However, no precipitates were observed in Figs. 1(d) and 1(e), indicating that the precipitates can be completely dissolved at temperatures above 1120 °C. M. Rajkumar's [4] phase diagram simulation results for CD3MWN steel show that the σ phase still exists in the steel at around 1080 °C. Since the calculation results describe the thermodynamic equilibrium conditions, while the test steel is in a near-equilibrium state during actual heat treatment and testing, there is a deviation between the test results and the calculation results. Therefore, when the test steel is heat-treated at 1100 °C, there are still a few undissolved σ phases in the microstructure. However, after holding at 1120 °C and 1140 °C for a period of time, the σ phase in CD3MWN steel has been completely dissolved.

(a) 1060 °C × 2 h

(b) 1080 °C × 2 h

(c) 1000 °C × 2 h

(d) 120 °C × 2 h

(e) 1 140 ℃×2 h

Figure 1: Microstructure of CD3MWN test steel at different heat treatment temperatures

Figure 2 Morphology of precipitated phases produced by heat treatment at 1060 ℃

Figure 3 Electron diffraction pattern of the precipitated phase

Table 2 Element Content of Precipitated Phases

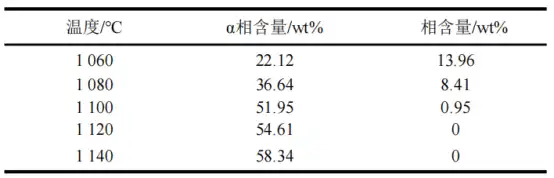

Table 3 shows the ferrite phase content and the detection results of phase content. As the heat treatment temperature increases, the ferrite phase content rises. At 1100 ℃, the ratio of ferrite phase to austenite phase approaches 1:1.

Table 3 Content of α phase and σ phase of the test steel at different solution treatment temperatures

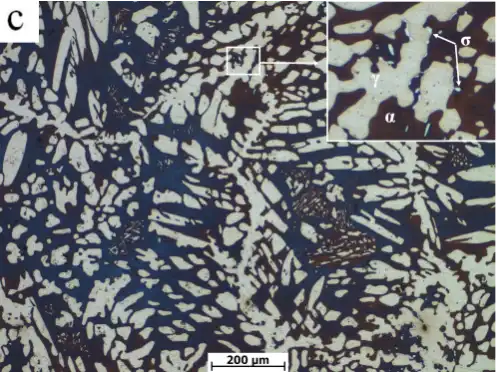

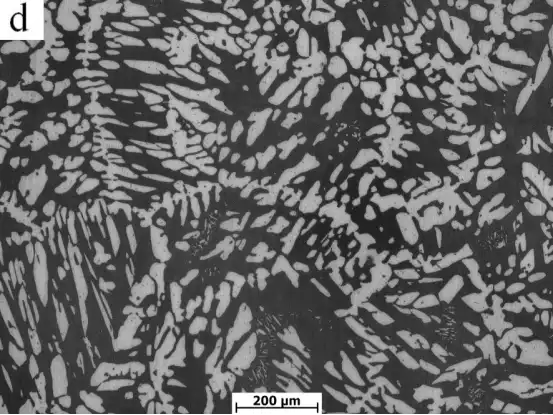

2.1.2 Furnace cooling followed by water quenching

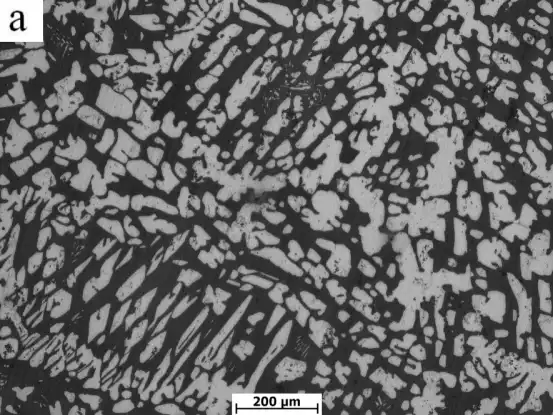

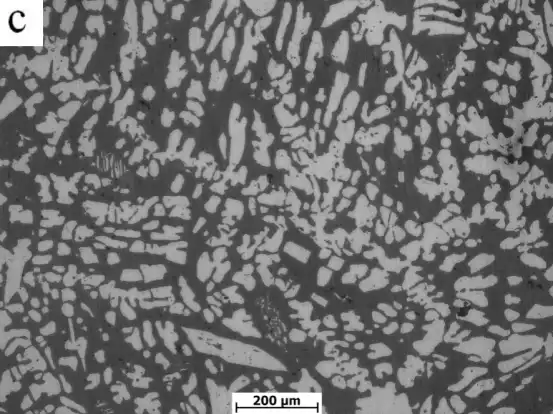

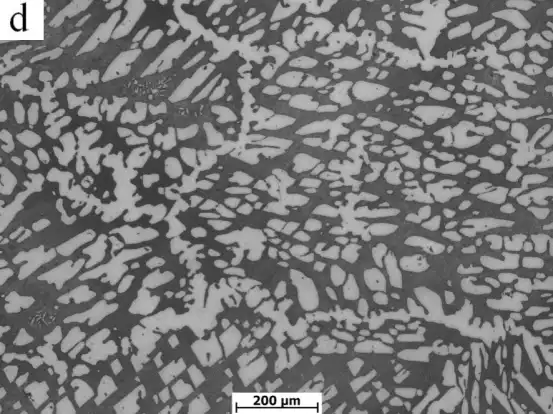

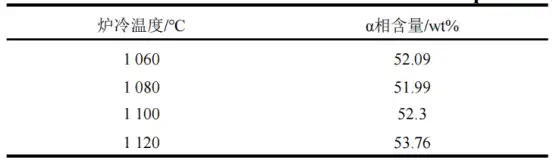

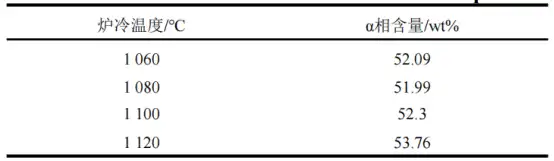

Figure 4 shows the microstructure morphology after holding at 1140 ℃ for 2 h and then furnace cooling to different temperatures before water quenching. It can be seen that, compared with direct water quenching, no σ phase precipitates in the microstructure after furnace cooling followed by water quenching. The microstructure consists of austenite and ferrite phases, with fewer elongated austenite phase regions and a more uniform and smooth austenite structure. The austenite grains gradually spheroidize [5-6]. The ferrite content detection results are shown in Table 4. Compared with direct water quenching, the ratio of the two phases is closer to 1:1 and varies less with the change of heat treatment temperature.

(a) 1060°C

(b) 1080℃

(c) 1100℃

(d) 1120℃

Figure 4 Microstructure of CD3MWN test steel at different furnace cooling temperatures

Table 4 Content of α phase of test steel at different furnace cooling temperatures

Research shows that the most sensitive temperature for σ phase precipitation in CD3MWN steel is approximately 950 ℃. Therefore, the nose temperature of the isothermal transformation curve of σ phase in CD3MWN is about 950 ℃. Meanwhile, 1060 ℃ and 1080 ℃ are close to the upper limit of the σ phase precipitation temperature, and it takes a relatively long time to precipitate σ phase at these temperatures. When water quenched after furnace cooling, after heating and holding at 1140 ℃ for 2 hours, all the precipitated phases in the as-cast CD3MWN steel have completely dissolved, and the distribution of Cr, Mo, Ni and other elements in α and γ phases tends to be uniform, and the compositions of the two phases are more similar [8]. During the furnace cooling process, the steel is taken out for water quenching when cooled to the set temperature, and the holding time at this temperature is not long, so the diffusion of Cr, Mo and other elements is insufficient, and the aggregation of Cr and Mo elements cannot be formed, which affects the precipitation of σ phase.

2.2 Effects of Heat Treatment on Mechanical Properties

2.2.1 Impact Toughness

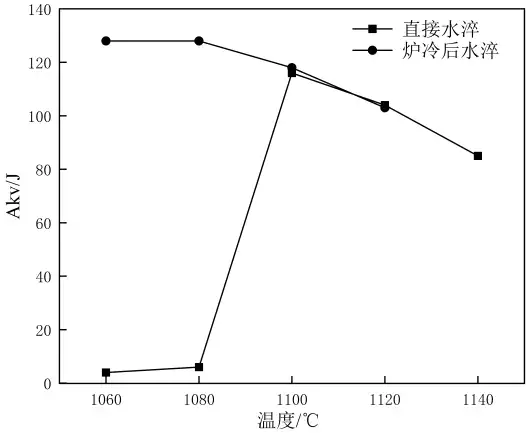

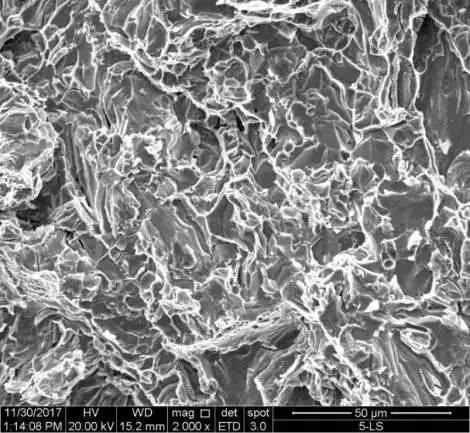

Figure 5 shows the variation of room-temperature impact toughness of CD3MWN steel under different heat treatment processes. It can be seen from the figure that when direct water quenching is adopted, the σ phase has a significant influence on the impact toughness of CD3MWN steel. When the content of the σ phase is high, the impact toughness is only 4 J at 1060 °C and 6 J at 1080 °C. This is because the σ phase has high hardness and brittleness, and a tetragonal crystal structure. It often precipitates at the interface between ferrite and austenite and at the ferrite grain boundaries, pinning dislocation slip and hindering dislocation movement, resulting in planar dislocation pile-ups and making dislocation movement difficult. At the same time, the dislocation slip distance becomes shorter, generating a certain strengthening effect, but reducing plasticity. As shown in Figure 6(a), a distinct cleavage fracture surface can be seen, with almost no ability to absorb impact energy. Compared with the low-temperature impact toughness, the influence of the σ phase content on the room-temperature impact toughness of duplex stainless steel is smaller when the σ phase content is low [9]. At 1100 °C, due to the extremely low content of the σ phase, the impact performance is mainly affected by the ratio of the two phases, and the room-temperature impact toughness can still reach 117 J. At 1120 °C and above, the σ phase is completely dissolved. With the increase of heat treatment temperature, the content of the hard and strong α phase increases, while the content of the soft and tough γ phase decreases. The test steel shows a trend of decreasing impact energy. As shown in Figure 6(b), the impact fracture surface morphology of the test steel after heat treatment at 1120 °C is distributed with dimples of different sizes. The black spots in the figure are inclusions in the test steel, which fall off from the matrix first at the time of fracture and become the center of the dimples.

Figure 5 Impact properties at different heat treatment temperatures

(a) 1,060 °C

(b) 1,120 ℃

Figure 6 shows the impact fracture morphology of the test steel. When the furnace cooling followed by water quenching process is adopted, the impact performance of CD3MWN steel is mainly affected by the proportion of the two phases. With the change of the proportion of the two phases, the impact toughness shows a slow downward trend.

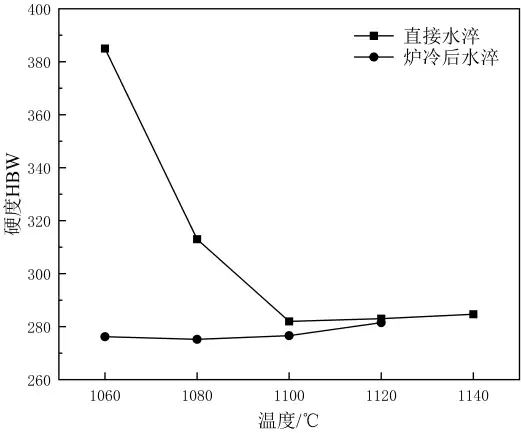

2.2.2 Surface Hardness

Figure 7 shows the variation of surface hardness of CD3MWN steel under different heat treatment processes. When directly quenched in water, the hardness of CD3MWN steel is relatively high at 1060 ℃ and 1080 ℃. With the increase of solution temperature, the hardness value tends to stabilize, which is consistent with the above-mentioned σ phase precipitation temperature rule. However, when the furnace cooling followed by water quenching process is adopted, the hardness values of CD3MWN steel tend to stabilize. As the furnace cooling temperature increases, the proportion of ferrite phase rises, and the hardness value shows a slightly upward trend.

Figure 7 Hardness at Different Heat Treatment Temperatures

2.2.3 Tensile Properties

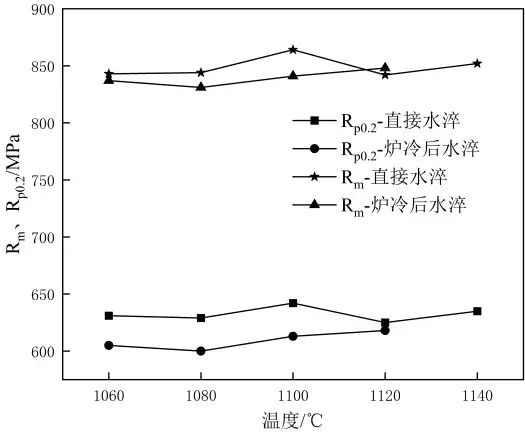

Figure 8 shows the variation of strength values of CD3MWN steel under two different heat treatment processes. It can be seen from the figure that when directly quenched in water, the yield strength and tensile strength of the test steel reach the maximum at 1100 ℃, slightly decrease at 1120 ℃, and then increase again at 1140 ℃.

The change in the proportion of ferrite and austenite phases and the precipitation of σ phase will have a certain impact on the mechanical properties of duplex stainless steel. Since the σ phase usually precipitates at the interface between ferrite and austenite and at the ferrite grain boundaries, it greatly damages the plasticity and toughness of the material. As shown in Figure 5, the existence of the σ phase has a significant impact on the plasticity and toughness of the material. However, at the same time, the σ phase is hard and brittle, with a hardness much higher than that of ferrite and austenite, and it also has a pinning effect on dislocations, which can effectively increase the strength of the alloy.

Figure 8: the tensile strength and yield strength of CD3MWN steel at different heat treatment temperatures.

It can be seen from Figure 8 that when directly quenched in water at 1100°C and below, the presence of the σ phase increases the tensile strength and yield strength of the material. At 1100°C direct water quenching, due to the dual strengthening effects of the body-centered cubic ferrite phase and the σ phase, the tensile strength and yield strength reach their maximum values. At 1120°C direct water quenching, the strengthening effect of the σ phase disappears, and the strengthening effect brought by the increase in ferrite is not enough to offset the strength loss caused by the dissolution of the σ phase, so the tensile strength and yield strength show a downward trend. At 1140°C direct water quenching, the ferrite content further increases, and the tensile strength and yield strength also further rise.

When furnace-cooled and then water quenched, the microstructure of the material is mainly ferrite and austenite two-phase structure. The ferrite content increases from 51.99% to 53.76%, resulting in a slow increase in yield strength and tensile strength. At 1120°C heat treatment, the ferrite content of the test steel is 54.61% in direct water quenching and 53.76% in furnace-cooled and then water quenched. The ferrite content of the test steel under the two heat treatment processes only differs by 0.85%. Due to the absence of the σ phase, the ratio of the two phases determines the tensile strength and yield strength of the test steel, and the tensile strength and yield strength of the two reach the same level.

2.3 The Impact of Heat Treatment Process on Castings Production

Due to the fact that duplex stainless steel is very soft at high temperatures, castings without sufficient support are prone to distortion and deformation, especially for large thin-walled castings, which is a very important issue. By shortening the heat treatment holding time, reducing the heating rate, or using a heat treatment temperature lower than the recommended value, deformation can be minimized. However, these efforts may prevent the precipitated phase from dissolving or lead to the formation of additional precipitated phases, thereby reducing the corrosion resistance and toughness of the castings. If the wall thickness of the castings is uneven, a high heat treatment temperature causes the thin-walled areas to cool faster than the thick areas during rapid cooling, resulting in temperature gradients and contraction differences in different parts. This often generates significant thermal stress within the castings, leading to deformation and even cracking.

In summary, during the production and processing of castings, to ensure satisfactory engineering properties of duplex stainless steel, the solution cooling process of furnace cooling followed by water quenching should be prioritized, with the furnace cooling temperature preferably set at 1080°C. This approach not only ensures a good balance between strength and plasticity but also reduces the risks associated with high-temperature water quenching for the castings. At the same time, prolonged stays within the temperature range sensitive to precipitated phases should be avoided. When performing solution treatment on CD3MWN steel castings in the production site, rapid cooling after solution treatment should be strictly controlled, and the castings should be quickly cooled through the brittle zone (750-1080°C). The water temperature in the cooling pool should be maintained below 25°C. For thin-walled and complex castings, anti-deformation and high-temperature anti-oxidation treatments should also be carried out.

3 Conclusions

(1) When CD3MWN super duplex stainless steel is directly quenched in water at temperatures below 1120 ℃, the amount of σ phase precipitated increases with the decrease of temperature, and the material has high strength and hardness. When directly quenched in water at temperatures above 1120 ℃, the σ phase is completely dissolved, and the ratio of ferrite phase and austenite phase is the decisive factor affecting the performance of CD3MWN steel.

(2) When CD3MWN super duplex stainless steel is quenched in water after furnace cooling, no σ phase precipitates in the microstructure, and it is a two-phase structure of ferrite and austenite. The ratio of the two phases approaches 1:1, and the amount of lamellar austenite decreases. As the furnace cooling temperature increases, the impact toughness of the test steel shows a downward trend, while the surface hardness and strength increase slowly.

(3) The best heat treatment method for CD3MWN steel should be the solution cooling process of quenching in water after furnace cooling, with the furnace cooling temperature selected at 1080 ℃. At this time, not only can a good match of strength and plastic toughness be ensured, but also the risk brought by high-temperature water quenching to the cast product can be reduced.