Knowledge

The Influence of Heat Treatment Process on the Properties of Precipitation-hardening Stainless Steel

17-4PH steel is a typical martensitic precipitation-hardening stainless steel, which has high strength and toughness as well as good corrosion resistance. After solution treatment at 1040℃, 17-4PH steel was subjected to single aging treatment at 480℃ and 550℃ respectively, and then to secondary aging at 550℃ after aging at 480℃. The mechanical properties and microstructure changes of the material under different heat treatment conditions were detected. The results show that the microstructure of 17-4PH steel after solution treatment and aging at 480℃ is martensite, while that after aging at 550℃ is tempered sorbite. The tensile strength and yield strength of 17-4PH steel are the highest when aged at 480℃, but the impact toughness is relatively low. With the increase of the single aging temperature, the strength of the steel decreases and the impact toughness increases when aged at 550℃. 17-4PH steel can obtain better comprehensive mechanical properties such as strength and impact toughness after solution treatment at 1040℃ and aging at 550℃.

17-4PH is a martensitic precipitation-hardening stainless steel, which features low carbon content, high nickel and chromium content, and good corrosion resistance. It also contains a considerable amount of alloying elements such as copper and niobium, which precipitate during heat treatment, strengthening the grain structure and endowing the material with high strength and hardness. Precipitation-hardening stainless steel achieves high strength and certain corrosion resistance by precipitating fine intermetallic compounds and a small amount of carbides during aging. Therefore, this material is widely used in aerospace, chemical, food, and nuclear power industries, among others. The main heat treatment methods for 17-4PH steel are solution treatment and aging treatment. The microstructure obtained after solution treatment is mostly martensite, with relatively high strength. Aging treatment is an adjustment treatment, and the required strength and hardness of the material can be obtained by aging at different temperatures. This paper studies the effects of different aging temperatures and methods on the mechanical properties and microstructure of 17-4PH steel after solution treatment.

1. Experimental Materials and Methods

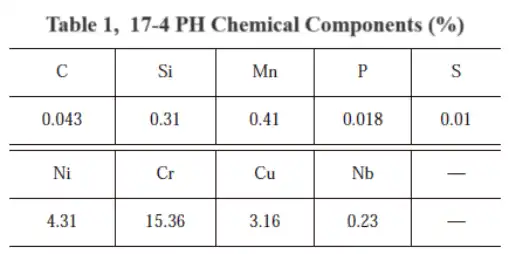

The 17-4PH steel specimens used in the experiment were steel rods with a specification of φ 60mm × 200mm. The chemical composition is shown in Table 1.

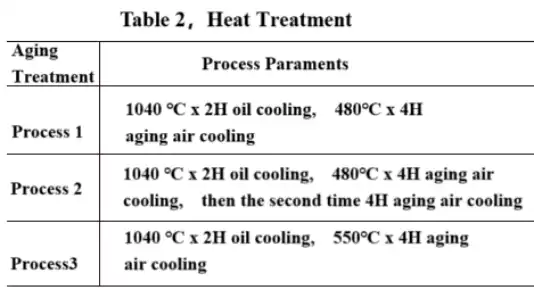

To study the changes in mechanical properties and microstructure of 17-4PH steel under different aging treatment temperatures, the samples were subjected to solution treatment and aging treatment at different temperatures. The 17-4PH stainless steel was solution treated in a vacuum furnace with a process of 1040℃ oil quenching, followed by three different aging treatment methods: aging at 480℃ for 4 hours in air; aging at 550℃ for 4 hours in air; and aging at 480℃ for 4 hours in air followed by aging at 550℃ for 4 hours in air. The heat treatment process is shown in Table 2.

Samples were taken from φ 60mm×200mm test bars of 17-4PH steel that underwent three different heat treatment processes to prepare tensile, metallographic and impact test specimens. Tensile tests were conducted using a WDW-100E electronic tensile testing machine in accordance with GB/T 228.1—2010 "Metallic Materials - Tensile Testing - Part 1: Method of Test at Room Temperature". Impact tests were carried out using a JB-300 impact testing machine in accordance with GB/T 229—2020 "Metallic Materials - Charpy V-notch Impact Test". Metallographic examination was performed using a MR5000 metallographic microscope to investigate the microstructure and mechanical properties of 17-4PH steel after solution treatment and at different aging temperatures. The changes in properties under different processes were analyzed.

2. Test Results and Analysis

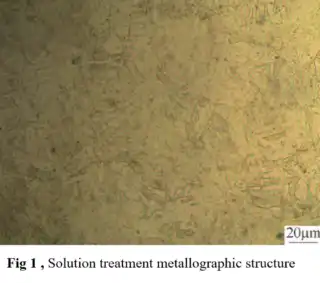

2.1 Metallographic Structure: The metallographic structure of 17-4PH steel under different processing conditions was observed at 500x magnification using a metallographic microscope. After solution treatment, the matrix of 17-4PH steel was lath martensite with relatively coarse grains and a relatively uniform structure, and no dense grain boundary precipitates were observed, as shown in Figure 1.

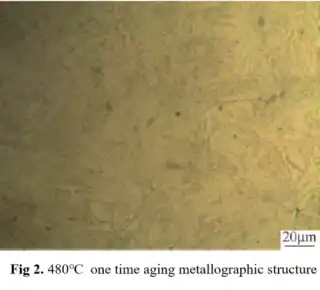

After a single aging treatment at 480℃, the microstructure is composed of martensite and a small amount of austenite. There are many fine black dot-like carbides on the martensite, as shown in Figure 2.

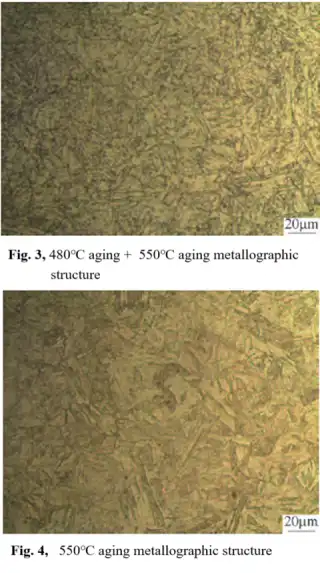

After a primary aging at 480℃ followed by a secondary aging at 550℃, the microstructure is lath martensite, but the grains are relatively finer and more evenly distributed, as shown in Figure 3. After a primary aging treatment at 550℃, martensite begins to decompose, and many fine carbides precipitate along the grain boundaries, with the microstructure being tempered sorbite, as shown in Figure 4. As the primary aging temperature increases, when the aging temperature reaches 550℃, martensite begins to decompose, and many fine carbides precipitate along the grain boundaries, with the microstructure being tempered sorbite that retains the martensite phase.

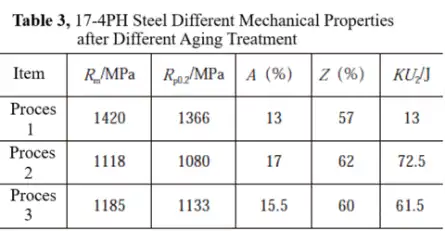

2.2 Mechanical Properties: The tensile properties and impact energy absorption at -40°C of 17-4PH steel after solution treatment at the same temperature and aging treatment at different temperatures of 480°C and 550°C are shown in Table 3.

It can be seen from Table 3 that under the treatment of the first aging temperature at 480℃ (Process 1) and the first aging temperature at 550℃ (Process 3), the tensile strength decreased from 1420 MPa to 1185 MPa, the yield strength decreased from 1366 MPa to 1133 MPa, the elongation after fracture increased from 13% to 15.5%, the reduction of area increased from 57% to 60%, and the impact absorption energy at -40℃ increased from 13 J to 61.5 J. Under the treatment of the first aging temperature at 480℃ (Process 1) and the second aging temperature at 550℃ after the first aging temperature at 480℃ (Process 2), the tensile strength decreased from 1420 MPa to 1118 MPa, the yield strength decreased from 1366 MPa to 1080 MPa, the elongation after fracture increased from 13% to 17%, the reduction of area increased from 57% to 62%, and the impact absorption energy at -40℃ increased from 13 J to 72.5 J. The mechanical properties of 17-4PH steel under the treatment of the first aging temperature at 480℃ and the second aging temperature at 550℃ (Process 2) and the first aging temperature at 550℃ (Process 3) changed little. However, as the first aging temperature increased from 480℃ to 550℃, the strength of 17-4PH steel began to decrease, while the toughness of the steel improved.

3. Conclusion

1) The matrix of 17-4PH steel after solution treatment and aging is martensite.

2) When 17-4PH steel is solution treated at 1040℃ and aged at 480℃, it has the highest tensile strength and yield strength, but the impact energy absorption at -40℃ is relatively low. As the aging temperature increases, the tensile strength and yield strength both show a downward trend, while the elongation after fracture, reduction of area, and impact energy absorption increase.

3) Under the same solution treatment process, when a secondary aging at 550℃ is added after a primary aging at 480℃, the tensile strength and yield strength of 17-4PH steel both decrease, but the toughness of the steel improves. There is no significant difference in mechanical properties between a primary aging at 480℃ followed by a secondary aging at 550℃ and a single aging at 550℃.

4) 17-4PH steel achieves better comprehensive mechanical properties after solution treatment at 1040℃ and a single aging at 550℃. Therefore, in actual heat treatment production, the appropriate heat treatment method can be selected based on the mechanical properties required by the product.

Vigor has more than 20 years of experience in producing and supplying OEM castings, forged parts, and CNC machined parts. We have a strong capability for different heat and post-treatment. If anything we can help, please contact us soon. info@castings-forging.com