Knowledge

The Influence of 28 Elements on the Properties of Iron and Steel Castings

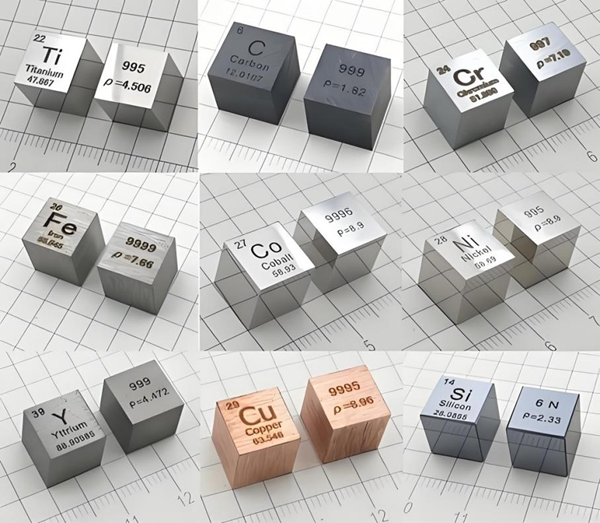

Steel, as a core material in modern industry, has its properties determined by the 28 elements dissolved or precipitated in the iron matrix. These elements significantly influence the strength, toughness, corrosion resistance and processability of steel through mechanisms such as solid solution strengthening, second phase precipitation and grain boundary regulation. This paper systematically reviews the action mechanisms of major elements such as carbon, silicon and manganese, as well as trace elements like boron, niobium and titanium, and reveals the scientific laws of element synergy design by combining application cases of typical steel grades.

I. The Regulatory Role of Major Elements on Steel Properties

1. Carbon (C): The Balancer of Strength and Toughness

Carbon is the most important alloying element in steel. When its content varies within the range of 0.02% to 2.11%, it has a fundamental impact on the properties of steel.

Solid solution strengthening: Carbon atoms dissolve into the ferrite lattice, causing lattice distortion. For every 0.1% increase in carbon content, the yield strength increases by approximately 50 MPa. For instance, the tensile strength of 45# steel (with a carbon content of 0.42% - 0.50%) reaches 600 MPa, while that of 20# steel (with a carbon content of 0.17% - 0.23%) is only 410 MPa.

Phase transformation control: When the carbon content exceeds 0.3%, the critical cooling rate of steel significantly decreases, and the martensite transformation temperature (Ms point) drops from 280°C (0.1% C) to 200°C (0.8% C), directly affecting the quenching process design.

• Toughness loss: When the carbon content exceeds 0.6%, the impact toughness of steel drops sharply. The Charpy V-notch impact energy at -20°C decreases from 50J (0.3% C) to 15J (0.8% C).

Application case: For automotive gears made of 20CrMnTi steel, by controlling the carbon content within the range of 0.17% to 0.23% and combining with carburizing treatment, a performance combination of surface hardness of 58-62 HRC and core toughness above 30J is achieved.

2. Silicon (Si): A Contradiction of Thermal Strength and Electrical Conductivity

Silicon, as a deoxidizer and alloying element, has a dual role:

Solid solution strengthening: The solubility of silicon in ferrite can reach 4%. For every 0.1% increase in silicon content, the yield strength increases by approximately 10 MPa. For instance, the tensile strength of the spring steel 60Si2Mn with 1.5% silicon content reaches 1275 MPa.

• Enhanced thermal strength: Silicon increases the recrystallization temperature of ferrite, tripling the creep strength of steel at 550°C. By adding 0.17% to 0.37% silicon to boiler tube steel 12Cr1MoV, the creep strength at 600°C for 10⁵ hours can reach ≥100 MPa.

Conductivity impairment: When the silicon content exceeds 2%, the resistivity of steel increases from 15 μΩ·cm (pure iron) to 45 μΩ·cm, which limits its application in electrical steel.

Typical application: Grain-oriented silicon steel contains 2.8% - 3.5% silicon. By suppressing the development of {110}<001> texture, the magnetic induction B8 can reach 1.92T, and the iron loss P1.7/50 can be reduced to 0.95W/kg.

3. Manganese (Mn): Deoxidation, desulfurization and improvement of hardenability

Manganese plays multiple roles in steel:

Deoxidation and desulfurization: Manganese forms MnS with sulfur, which has a melting point of 1600°C, avoiding the hot brittleness caused by FeS (with a melting point of 989°C). For instance, in Q345B steel with 0.7% to 1.0% manganese content, the sulfur content can be controlled below 0.025%.

• Improved hardenability: Manganese reduces the critical cooling rate of steel, enabling 42CrMo steel plates with a thickness of 40mm to achieve a fully martensitic structure when quenched in oil.

Low-temperature toughness impairment: When the manganese content exceeds 1.5%, the ductile-to-brittle transition temperature (DBTT) of steel rises from -40°C (0.5% Mn) to -10°C (2.0% Mn).

Engineering Practice: For the bucket teeth of excavators, Mn13 steel is used. By controlling the manganese content within 11% to 14% and combining with water quenching treatment, the wear resistance with impact toughness above 200J/cm² is achieved.

II. Precise Regulation of Steel Properties by Trace Elements

1. Boron (B): The Microalloying Revolution for Hardenability

The solubility of boron in steel is only 0.002%, but its effect is significant:

Hardening penetration improvement: 0.0005% boron can increase the critical diameter of 20mm thick 40Cr steel from 12mm to 22mm, which is equivalent to adding 0.5% nickel.

Grain boundary strengthening: Boron accumulates at the austenite grain boundaries, inhibiting ferrite nucleation and shifting the continuous cooling transformation (CCT) curve to the right. For instance, in 20MnB steel with 0.003% boron content, bainite structure can be obtained under air cooling conditions.

Heat treatment sensitivity: Boron steel requires strict control of heating temperature (880-920℃). Overheating will cause borides to precipitate, resulting in the loss of hardenability effect.

Typical steel grade: 50B steel for automotive seat belt spring, by adding 0.0008% - 0.003% boron, achieves a fatigue life of over 10⁷ cycles for the spring.

2. Niobium (Nb): The Nanoengineer for Fine Grain Strengthening

The strengthening of steel by niobium through nano-scale precipitates:

Grain refinement: 0.03% niobium can reduce the austenite grain size of X70 pipeline steel from 50 μm to 10 μm and increase the yield strength by 100 MPa.

Precipitation strengthening: niobium forms NbC phases with a size of 5-10 nm in ferrite. For every 0.01% increase in niobium, the strength increases by approximately 30 MPa. For instance, Q345qE bridge steel with 0.04% niobium has a yield strength of 460 MPa.

• Improved welding performance: Niobium reduces the tendency of embrittlement in the heat-affected zone (HAZ) of steel, enabling the shear area ratio of the drop weight tear test (DWTT) of X80 steel to exceed 85%.

Application example: By adding 0.02% - 0.05% niobium to EH40 steel used in offshore platforms and combining it with controlled rolling and controlled cooling processes, the low-temperature toughness with an impact energy of ≥ 100J at -60℃ is achieved.

3. Titanium (Ti): The Expert in Controlling Sulfide Morphology

Titanium plays multiple roles in steel:

Sulfide modification: Titanium forms Ti4C2S2 with sulfur, which has a melting point of 1800°C, to prevent the anisotropy of MnS. For instance, in SAE10B21 cold heading steel containing 0.02% titanium, the anisotropy coefficient ΔR drops from 0.3 (without titanium) to 0.1.

Fine grain strengthening: During the austenitizing process of titanium, TiN particles with a size of 0.1-0.5 μm are formed, which inhibit grain growth. For instance, in N80 oil well tubes containing 0.015% titanium, the austenite grain size is stably maintained at 15 μm.

Hydrogen trapping effect: Titanium carbonitrides can capture hydrogen atoms, reducing the hydrogen-induced cracking (HIC) sensitivity of steel. For instance, the crack length rate (CLR) of X65 steel containing 0.02% titanium in NACE TM0284 solution decreased from 15% (without titanium) to 3%.

Typical application: 42CrMoTi steel for automotive drive shafts achieves a torsional fatigue life of over 10⁶ cycles by adding 0.03% to 0.06% titanium.

III. Control and Utilization of Harmful Elements

Sulfur (S): The Root Cause and Control of Hot Brittleness

The harm of sulfur in steel mainly lies in:

Hot brittleness: FeS forms an eutectic with Fe (melting point 989°C), causing cracking during hot working. For instance, steel with 0.05% sulfur content has a crack occurrence rate of 30% when rolled at 1150°C.

Anisotropy: MnS inclusions cause the longitudinal elongation of steel to be 20% - 30% higher than the transverse. For instance, in S20C steel with 0.03% sulfur, the longitudinal elongation after fracture A is 25%, while the transverse is only 18%.

Control technology: By calcium treatment (adding 0.002% - 0.005% Ca), MnS is transformed into spherical CaS, reducing the anisotropic coefficient ΔR from 0.25 to 0.05.

Engineering case: For AH36 steel used in ships, by controlling the sulfur content to be ≤ 0.005% and combining with calcium treatment, the Z-direction performance (Z15) requirements are achieved.

2. Phosphorus (P): Challenges and Responses to Cold Brittleness

The influence of phosphorus on the properties of steel is temperature-dependent.

Cold brittleness: Phosphorus accumulates at the ferrite grain boundaries, reducing the impact energy at -20°C from 50J (0.008%P) to 10J (0.03%P). For instance, the ductile-to-brittle transition temperature (DBTT) of Q235B steel with 0.025% phosphorus increases from -20°C to 0°C.

Solid solution strengthening: The solid solution strengthening effect of phosphorus is one-third that of carbon. For every 0.01% increase in phosphorus, the yield strength increases by approximately 10 MPa. For instance, 16Mn steel with 0.02% phosphorus has a yield strength of 345 MPa.

Control strategy: By adding 0.005% - 0.01% boron, the cold brittleness effect of phosphorus can be partially offset. For instance, 20MnB steel with 0.002% boron still maintains an impact energy of ≥ 34J at -40℃ when the phosphorus content is 0.02%.

Typical application: The EH36-Z35 steel for polar vessels achieves a low-temperature performance of an impact energy of ≥ 40J at -60℃ by controlling the phosphorus content to ≤ 0.015% and adding nickel (0.4%).

IV. Future Trends of Element Synergistic Design

With the development of high-end materials such as third-generation automotive steel and ultra-supercritical boiler steel, the element collaborative design shows the following trends:

Multi-element microalloying: By adding Nb, Ti and V in combination, the best balance between strength and toughness is achieved. For instance, the DP800 dual-phase steel with 0.03% Nb, 0.02% Ti and 0.05% V has a yield strength of 550 MPa and an elongation of 22%.

2. Nano-precipitation control: By using elements such as Cu and Ni to form precipitates of 2-5 nm in ferrite, the yield strength of Q690D high-strength steel is increased by 150 MPa.

3. Grain boundary engineering: By adding B and Nb in combination, the grain boundary characteristics distribution (GBD) of X100 pipeline steel was optimized to over 70%, and the impact energy at -20℃ was increased from 80J to 120J.

The synergistic effect of 28 elements in steel constitutes a complex system for material design. In the future, with the development of computational materials science and machine learning technology, the optimization of element combinations will shift from empirical trial and error to intelligent design, driving steel performance to a higher level. For instance, by establishing a deep learning model of elements-structure-performance, customized design of Q345 grade steel with a yield strength of 500 MPa, an elongation of 25%, and an impact energy of 50 J at -20℃ can be achieved, providing material support for the transformation and upgrading of the manufacturing industry.

Vigor team has more than 20 years experience in stainless steel casting production and the robust supply chain of different treatment. If anything we can help or any parts you want to develop, please contact us at info@castings-forging.om