Knowledge

The Future Development of Electric Drive Gearboxes

In the context of the electrification era, the electric drive system, as a key component in the fields of new energy vehicles, industrial automation, and renewable energy, is undergoing unprecedented technological innovation. As the core transmission device of the electric drive system, the electric drive gearbox plays a crucial role. This article mainly introduces the working principle, application scenarios, and future development trends of the electric drive gearbox.

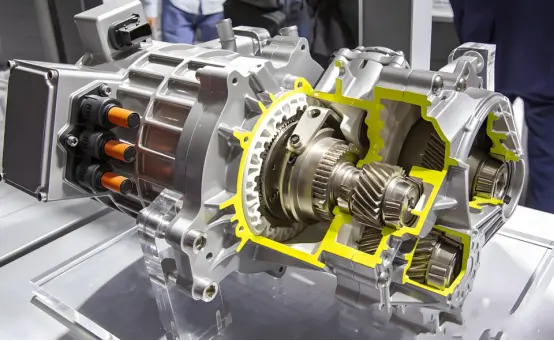

The basic working principle of an electric drive gearbox

1.1 Basic Structure and Working Principle

An electric drive gearbox is a precision mechanical device that converts the speed and torque output by an electric motor. It mainly consists of an input shaft, gear sets, an output shaft, a housing, and a lubrication system, etc. Its core function is achieved through gear meshing, including:

Speed regulation: By matching gears with different numbers of teeth, the speed of the electric motor can be increased or decreased.

Torque conversion: According to the principle of conservation of energy, when the speed decreases, the torque increases accordingly.

Change in power transmission direction: By using special gear sets such as bevel gears, the transmission direction can be adjusted.

Typical transmission ratio calculation formula: i = n₁/n₂ = z₂/z₁

Here, i represents the transmission ratio, n₁/n₂ represents the input/output speed, and z₁/z₂ represents the number of teeth of the driving/driven gear.

1.2 Differences from Traditional Gearboxes

Input Characteristics:

Electric motors have constant power/constant torque characteristic curves.

Instantaneous peak torque can reach 2-3 times the rated value.

Wide speed range (typically 0-15,000 rpm)

Dynamic response requirements:

It needs to match the rapid start and stop characteristics of the motor.

The commutation shock is more frequent and intense.

System integration degree:

Often highly integrated with motors and controllers

Electromagnetic compatibility issues need to be considered

The design of electric drive gearboxes

2.1 Key Technologies in Gear Design

Tooth Profile Optimization:

Adopting modified designs (such as crowned teeth) to reduce meshing impact

Optimizing micro-geometric parameters (pressure angle, module selection)

Application of new tooth profiles such as double circular arc gears

Material Selection:

Commonly used carburized steels like 20CrMnTi and 20CrMnMo

Special alloy steels like S135M for high-end applications

Surface Treatment:

Carburizing and quenching (case depth 0.8-1.2mm), DLC coating

Strength Calculation:

Contact and bending fatigue checks based on ISO 6336 standard

Considering impact load factors under electric operation conditions (typically 1.8-2.5)

2.2 Vibration and Noise Reduction Design

Vibration Control:

Using helical gears (helix angle 15-25°) instead of spur gears

Optimizing overlap ratio (ε>1.3)

Installing damping rings and other vibration reduction structures

NVH Optimization:

Controlling tooth surface roughness (Ra<0.4μm)

Performing edge and root modification

Conducting box modal analysis (first natural frequency >3000Hz)

2.3 Lubrication and Sealing System

Lubrication Scheme:

Splash lubrication (speed <5000rpm)

Forced lubrication (with independent oil pump)

New lubricating oil: Polyalphaolefin synthetic oil (viscosity at 100℃ 6-8cSt)

Sealing Technology:

Radial shaft seals (temperature range -40~150℃)

Combination design of labyrinth seals and air seals

Integrated sealing modules

2.4 Thermal Management Design

Thermal Power Loss Calculation:

Ploss = Pin*(1-η)

Where η is typically 97-98% (for single stage)

Cooling Methods:

Natural cooling (<3kW)

Oil cooling (with oil channels in the box)

Water cooling (with integrated cooling jacket)

The Application of Electric Drive Gearboxes

3.1 New Energy Vehicles

Passenger Vehicles:

Single-stage reducer (transmission ratio 6-10)

Two-speed transmission (improves high-speed efficiency by 15%)

Integrated electronic differential design

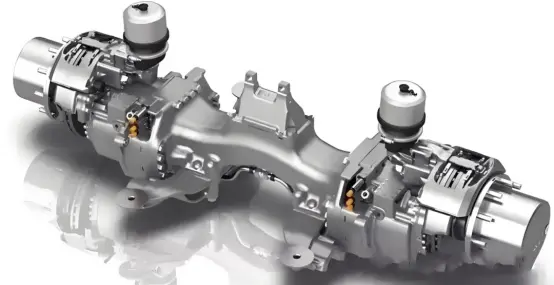

Commercial vehicles:

Multi-speed electric drive axle (4-speed AMT)

Central drive + wheel-side reduction combination

Torque capacity over 3000 Nm

3.2 Industrial Automation

Servo reducer (backlash < 3 arcmin)

Right-angle hollow reducer

Quick-change modular design.

3.3 Renewable Energy

Wind turbine gearboxes (power > 8MW)

Reduction gears for photovoltaic tracking systems

Variable speed devices for wave power generation

4. Technical Challenges and Development Trends

4.1 Current Technical Bottlenecks

Material Limitations:

The contact fatigue limit of current gear steel is approximately 1500 MPa.

Bearing dn value limitation (about 3×10⁶ mm·rpm).

Efficiency Enhancement:

Single-stage efficiency has reached 98%, leaving limited room for further optimization.

Increased no-load loss ratio (under low-load conditions).

Cost Pressure:

The cost of precision gear processing accounts for over 40%.

The cost of special lubricating oil remains high.

4.2 Future Development Trends

Innovative Structural Design:

Planetary + Parallel Axis Compound Transmission

Magnetic Gears (Contactless Transmission)

3D Printed Topology Optimized Structures

Smart Gearboxes:

Integrated Vibration and Temperature Sensors

Predictive Maintenance Based on Digital Twins

Self-Learning Lubrication Regulation System

New Materials Application:

Nanocrystalline Gear Steel (30% Strength Enhancement)

Ceramic Hybrid Bearings

Graphene Reinforced Composite Material Gears

System-Level Optimization:

Coordinated Design of Motor - Reducer - Controller

Transmission Efficiency Map Optimization

Life Prediction Model Based on V2G

Summary

As a key link in the conversion of electromechanical energy, the technological progress of electric drive gearboxes directly affects the performance improvement of the entire electric drive system. In the next decade, electric drive gearboxes will rapidly evolve towards higher efficiency, higher power density, intelligence, and lower cost. Especially in the field of new energy vehicles, the popularization of new technologies such as 800V high-voltage platforms and SiC motors has put forward more stringent reliability requirements for gearboxes, which will continuously drive technological innovation and industrial upgrading in the industry.