Knowledge

The Causes and Improvements of Cracks in Thick, Large and Complex High Manganese Steel Castings

High manganese steel mainly refers to a material that rapidly hardens on the surface of steel structures under large impact loads and has wear resistance. The slower the crack propagation speed during its long-term use, the lower the probability of safety accidents. Currently, high manganese steel castings are widely used in multiple industries. Due to the larger linear shrinkage parameter and smaller heat transfer coefficient of high manganese steel compared to carbon steel, during the solidification and heat treatment of high manganese steel castings, high thermal stress is easily generated due to uneven temperature distribution and large temperature differences in the castings, causing crack problems. Especially for complex high manganese steel castings with a thickness of over 120mm, it is difficult to control the crack problem during production.

1. Crack Analysis of High Manganese Steel Castings

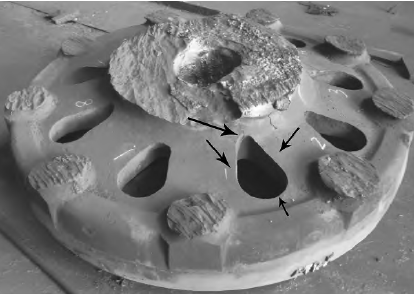

At present, there are many studies on the mechanism of work hardening treatment, heat treatment process, and casting process of high manganese steel, but few on the crack problem of high manganese steel castings. However, during the use of high manganese steel castings, various safety hazards are often encountered due to crack problems in the castings. Among them, the high manganese steel leading wheel casting, as a key part of the excavator's electric shovel, its quality and size will affect the subsequent use of the equipment. Due to the complex structure of the high manganese steel leading wheel casting and the maximum wall thickness of 142mm, the control of crack problems during production is not ideal. During the production of complex thick high manganese steel castings, after the pre-treatment of the castings by radiographic testing technology, it was found that there were cracks of different sizes on both sides of the two holes and the arc position. The actual length of most cracks was 25mm, and a few were around 50mm, as shown in Figure 1, which affected the service life and yield rate of high manganese steel castings. Therefore, during the early diagnosis period, it is necessary to analyze and study the causes of crack formation in high manganese steel castings.

2. Experimental Materials and Methods

2.1 Experimental Materials

During the research period of this study, the main research material was the ZG100Mn13 high manganese steel casting. After smelting in an electric furnace, vacuum refining was carried out to control the oxygen content in the steel water and the oxidation tendency of alloy elements. Then, samples were taken from the casting test blocks, and after chemical analysis, a detailed chemical composition table was obtained, as shown in Table 1. According to the provisions of the national standard GB/T 5680—2023 "Austenitic Manganese Steel Castings", the chemical composition of the castings was classified.

2.2 Test Methods

To conduct a detailed inspection of the crack samples of high manganese steel castings, it is necessary to use PT dye on the surface of the castings to accurately display the location and direction of surface cracks. Then, a 20mm×25mm×20mm crack sample is cut at the crack location. If there is a complete crack on the surface of the casting, the size of the crack sample should be appropriately adjusted, usually within the range of 30mm×30mm×20mm. After polishing the sample, it is immersed in a 4% nitric acid alcohol solution for 6 seconds, then taken out and placed under the lens of an optical microscope or other scanning equipment to observe the microstructure and crack conditions of the casting, and to analyze and determine the causes of crack formation in detail.

3 Analysis of the Causes of Cracks in High Manganese Steel Castings

3.1 Material and Metallurgical Factors

According to the test and detection work, the unreasonable control of chemical composition is the main factor causing cracks in high manganese steel castings. When the chemical composition is unreasonable, the performance of high manganese steel deteriorates, leading to obvious cracks on the surface of the casting. In current analyses, when the carbon and phosphorus content in high manganese steel exceeds the standard, the risk of gradual crack formation increases. Excessive carbon content, after heat treatment, leads to the precipitation of carbides at the grain boundaries, increasing the risk of grain boundary cracking and being a major factor causing cracks in high manganese steel castings. Moreover, when the phosphorus content in the material increases, it easily leads to the formation of brittle phosphorus eutectics, reducing the strength and toughness of the grain boundaries and lowering the overall performance of the steel casting. Additionally, during the metallurgical process of high manganese steel castings, existing defect issues are also key factors affecting material performance. Defects such as shrinkage cavities, gas holes, and slag inclusions during metallurgy create stress concentration points in the material, which are prone to cracking under external forces. Furthermore, if the content of FeO and MnO in the molten steel exceeds 2%, it further aggravates the brittleness of the grain boundaries and increases the probability of material cracking under stress.

3.2 Casting Process Defects

During the production of high manganese steel castings, if the casting temperature is not controlled in a timely manner, it can easily affect the quality of the castings. If the casting temperature is too high during casting, the solidification time after casting will be prolonged, resulting in a coarse crystal structure, which not only affects the overall performance of the casting but also increases the thermal stress of the subsequent casting, further exacerbating the crack problem. Conversely, if the casting temperature is too low, the fluidity of the molten metal weakens, making it difficult to ensure the filling effect of the mold, and during solidification, it may cause cold shuts or insufficient feeding, seriously affecting the integrity and density of the casting. Additionally, in research, it has been found that uneven cooling after casting and insufficient shrinkage allowance can also cause cracks in thick and complex high manganese steel castings. Generally, the cooling time of thick parts of high manganese steel castings is longer, while the cooling speed of thin-walled areas is shorter. Due to the thickness difference, the temperature difference during cooling is too large, and the stress concentration is more obvious, leading to gradual deformation or cracking of high manganese steel. Under the influence of the shrinkage allowance of the mold, the hindrance during solidification contraction increases the tensile stress, thereby increasing the risk of casting cracking. Moreover, risers, which are used to feed the shrinkage cavities formed during the solidification of castings, if they have unreasonable design issues, such as a diameter less than 1.5 to 2 times the thickness of the hot spot, or if they are cut at low temperatures, will definitely lead to an insufficient feeding effect of the riser, gradually resulting in insufficient local feeding and causing severe stress concentration. In severe cases, it may even lead to the scrapping of the casting.

3.3 Defects in Heat Treatment Process

At present, during the production of thick and complex high manganese steel castings, insufficient heating rate and holding time are common problems in the heat treatment process and are the main factors causing cracks in high manganese steel castings. During heat treatment, if the actual heating rate is too fast or the castings are not preheated properly in a timely manner, it will lead to a large temperature difference between the inside and outside of the castings after pre-treatment, resulting in concentrated thermal stress. This not only affects the stability and mechanical properties of high manganese steel castings but also causes quality defects such as cracks. In addition, due to the high carbon content in the material during heat treatment, a large amount of carbides will be produced, which is harmful to the quality of high manganese steel castings. As carbides are hard in texture, if they are not controlled during heat treatment, it will definitely lead to a decrease in the toughness of the grain boundary structure, increase the risk of casting cracking, and reduce the comprehensive performance of the casting, causing serious harm to subsequent processing and use.

3.4 Unreasonable Design Structure

During the structural design of thick and complex high manganese steel castings, due to factors such as excessive wall thickness differences, too small fillet radii in transition areas, or sudden changes in cross-sections in the structure, the problem of stress concentration in high manganese steel castings is quite obvious, resulting in a decrease in the final production quality. Stress concentration is a common harmful problem in structural mechanics. Once a casting structure has a stress concentration problem, it often leads to the structure bearing excessive loads and premature damage. When the wall thickness difference is too large, the stress distribution in the thin and thick areas of the high manganese steel casting is not uniform, and the thin areas often need to bear more stress, leading to plastic deformation or fracture. At the same time, if the fillet radii in transition areas are too small, the stress in the transition areas will continuously increase during the use of the casting, and the local stress will exceed the average stress acceptance level of the casting, thereby causing cracking. In addition, during the current structural design of high manganese steel castings, the generation of "+" shaped structures can also cause stress concentration, leading to high manganese steel castings being in a highly stressed state for a long time, and they are prone to fatigue damage or brittle fracture during use.

4 Improvement Measures for Cracks in High Manganese Steel Castings

4.1 Optimization of Chemical Composition of High Manganese Steel Castings

Firstly, to effectively control the crack problem of thick and complex high manganese steel castings, the chemical composition can be optimized during casting. By strictly controlling the content of carbon, sulfur, and phosphorus elements, the toughness of high manganese steel castings can be improved, thereby reducing the occurrence of cracks. Moreover, according to the usage requirements of thick and complex high manganese steel castings, the content of carbon elements should be controlled to control the hardness of the castings and avoid excessive internal stress in the casting structure, thereby reducing the risk of crack formation. Secondly, during the smelting of high manganese steel castings, refining techniques such as vacuum degassing and ladle refining can be adopted to effectively remove carbon, sulfur, and phosphorus elements from the material. If the content of sulfur and phosphorus elements in the material is too high, it will seriously reduce the toughness of high manganese steel castings and increase the probability of crack formation. Finally, carbon is the main alloying element in high manganese steel and has an important impact on improving the hardness and toughness of the castings. To ensure the usage effect of thick and complex high manganese steel castings, the actual content of carbon elements should be controlled according to the usage environment and performance requirements of the castings, thereby improving the balance between hardness and toughness of high manganese steel castings and enhancing their quality and performance.

4.2 Improvement of Casting Process of High Manganese Steel Castings

Effectively improving the dimensions and wall thickness of high manganese steel castings and strictly controlling the actual pouring temperature during pouring can ensure uniform heat dissipation during the solidification of the castings. Due to the uneven local heat dissipation of high manganese steel structures, it can lead to excessive internal temperature differences and stress concentration. Therefore, precise control of the pouring temperature can ensure the uniform cooling effect of the castings during solidification and heat dissipation, thereby improving the quality of casting production. At the same time, during the cooling period, it is necessary to timely control the cooling rate and the shrinkage of the mold. By controlling the type, flow rate and temperature of the cooling medium, the control effect of the cooling rate can be enhanced. Meanwhile, improvements should be made to the mold material and design methods to enhance the free shrinkage ability of the castings during cooling, thereby effectively reducing the internal stress and crack formation of the castings. As for the design of the pouring system, by optimizing the layout and dimensions of the pouring system, the fluidity of the molten metal can be enhanced, ensuring that the molten metal flows smoothly and evenly into the mold cavity, avoiding stress concentration caused by local overheating, and improving the filling capacity of the molten metal. This can also timely improve the microstructure of the castings, achieving a full improvement in the mechanical properties of high manganese steel castings.

4.3 Improve Heat Treatment Process

During the heat treatment process of high manganese steel castings, material properties and casting dimensions are the main factors affecting the heat treatment effect. Therefore, during heat treatment, it is necessary to scientifically and reasonably control the quenching temperature and heating rate. During the quenching process of the castings, technicians must ensure the uniform heat dissipation effect of the internal structure to avoid problems caused by uneven heat dissipation. At the same time, control the tempering process, and timely adjust the tempering temperature, time and atmosphere parameters to ensure that the castings can fully release the internal stress during tempering, enhance the toughness and stability of the castings, thereby avoiding deformation or arrangement problems of the castings during subsequent use, further enhancing the comprehensive mechanical properties and applicability of thick and complex high manganese steel castings, and reducing safety issues caused by crack formation in high manganese steel castings.

In addition, currently, water toughness treatment and cooling treatment are the main heat treatment technologies used. During water toughness treatment, thick and complex high manganese steel castings need to be held at 650°C to ensure the balance of internal and external temperature differences of the castings. Then, the temperature is raised to the required temperature for water toughness treatment. During the cooling process, when thick and complex high manganese steel castings are quenched, violent cooling should be avoided. Spray cooling or staged cooling methods can be used.

4.4 Welding and Repair Technology

During the manufacturing of thick and complex high manganese steel castings, welding technology has a direct impact on the quality of the castings. Therefore, before welding operations, the crack area needs to be thoroughly cleaned to ensure the removal of impurities that can affect the welding quality and ensure the quality of the casting welding. During welding, the strength and reliability of the welded joint need to be analyzed to better ensure the subsequent use effect of the castings. Currently, to ensure the quality of welding, low heat input welding methods need to be used, such as manual arc welding. During manual arc welding, the heat generation during welding can be controlled to reduce hardening and deformation caused by welding heat, thereby ensuring the mechanical properties and corrosion resistance of the welded joints of thick and complex high manganese steel castings. After the welding work is completed, no heat treatment is required. The interlayer temperature should be controlled to avoid the impact on the quality of the welded joint due to heat accumulation. Through the control of welding and repair technology, the quality problems of the welded joints can be further improved, enhancing the performance and quality of thick and complex high manganese steel castings.

5 Conclusion

The cracks in thick and complex high manganese steel castings are the inevitable result of the combined effects of material, process, and structure. In order to better enhance the production effect of thick and complex high manganese steel castings, it is necessary to reasonably improve the chemical composition during the production period, optimize the casting process, strengthen the effect of heat treatment process, continuously improve the production quality of castings, further control the cracks of thick and complex high manganese steel castings, enhance the mechanical properties of castings in use, and promote the progress and development of related industries.