Knowledge

The Causes and Countermeasures of Overheating in Heat Treatment

Overburning in heat treatment refers to the phenomenon where the temperature during the heat treatment process is too high, exceeding the melting point of the low-melting eutectic phase in the alloy, causing partial melting of the alloy, resulting in surface nodules and the appearance of remelted phases in the internal structure. Overburning is a serious heat treatment error. Once severely overburned, it cannot be remedied and can only be scrapped.

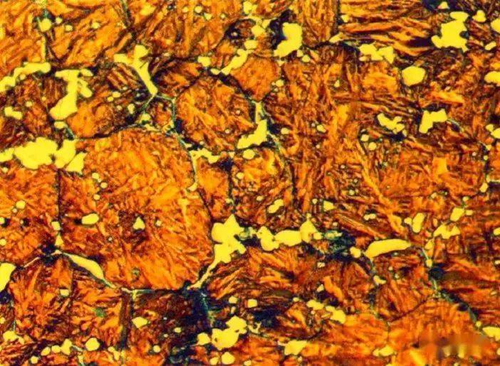

To enhance the strength of the alloy, the solution treatment temperature needs to be raised. When the temperature approaches the low-melting-point eutectic temperature of the alloy, due to inaccurate temperature control, the alloy temperature may become too high. A short period of excessive temperature generally does not cause severe overburning. In severe overburning, the alloy surface will develop nodules, while in less severe cases, the surface may show no change, but the metallographic structure will exhibit straight grain boundaries, spherical phase particles, and other phenomena. Overburning mainly affects the elongation of the alloy. If the mechanical properties, especially the elongation, meet the standards even with slight overburning, the alloy does not need to be scrapped. In actual production, to prevent overburning, the following measures can be taken.

1. Select a reasonable heating rate to avoid excessive heating speed and local overheating.

2. Adopt a segmented heating approach.

3. Regularly calibrate the temperature in the heating zone of the furnace.

4. Regularly calibrate the instruments to ensure accurate temperature control.

5. Optimize the furnace design to ensure a rational layout of heating elements, avoiding temperature gradients or hot spots, thereby reducing the possibility of local overheating.

6. Implement a strict process parameter recording and traceability system, saving temperature curve data after each heat treatment for analyzing potential overburn risks and continuously improving the operation process.

7. Conduct composition testing on alloy materials before they are stored in the warehouse to ensure that the content of low-melting-point elements meets the standards, reducing the probability of overburn from the source.

8. Combine computer simulation techniques, such as finite element analysis (FEA), to predict the temperature distribution during the heating process and adjust the process in advance to avoid critical temperature zones.

In addition, operators should receive regular professional training to enhance their ability to identify overburn signs, such as quickly judging organizational abnormalities through metallographic analysis, ensuring timely intervention at the early stage of slight overburn. Maintenance and upkeep of heat treatment equipment should also not be overlooked, including cleaning carbon deposits in the furnace and replacing aging components, to maintain stable heat conduction performance. Through these comprehensive measures, not only can overburn be effectively prevented, but also overall production efficiency and product quality stability can be improved.