Knowledge

Optimization of the Casting Process for High Manganese Steel Bucket Teeth

Instruction: Using high manganese steel as the material, the filling and solidification process of the bucket tooth casting was numerically simulated by the casting simulation software ProCAST. The simulation results show that the filling time of the pouring system is relatively long and the filling temperature is relatively high, which leads to the formation of large shrinkage porosity inside the bucket tooth casting. The pouring process parameters and the pouring system were optimized and the numerical simulation was carried out. The results show that after the process optimization, the surface quality of the bucket tooth casting is good, the internal solidification speed is accelerated, the process defects are reduced, and the scrap rate is lowered.

Keywords: High manganese steel; ProCAST; Filling time; Numerical simulation; Bucket tooth

The bucket tooth of the excavator is a key component. When the excavator excavates materials such as coal, the bucket tooth will experience impact and friction wear with the materials, and will also be subjected to significant impact loads [1]. Currently, most bucket teeth on the market have a short service life, and the economic loss caused by replacing bucket teeth is huge. The economic loss in China due to the failure of bucket teeth caused by wear is about 30 million yuan per year [2-3]. In addition, the bucket tooth may break during operation, even threatening the personal safety of the workers [4]. The mainstream bucket teeth are mainly divided into forged bucket teeth and cast bucket teeth. Forged bucket teeth have higher strength, but the cost is higher and the production process is more complex; the casting process has a lower cost, a simpler process, and is easy to produce in large quantities [5-6]. Currently, cast bucket teeth still dominate the market, but due to their larger grain size and lower strength, even after heat treatment, it is difficult to eliminate the defect of larger grain size. In addition, bucket teeth produced by the casting process inevitably have some surface defects [7-8], and may even have more serious shrinkage porosity and shrinkage cavity defects, with a high scrap rate, which has always been a difficult problem for enterprises. With the development of computer simulation technology, the integration of computer simulation technology with casting production has become a trend. Simulating the filling and solidification process of the bucket tooth through a computer can display the dynamic process of the molten metal in the mold cavity and provide guidance for actual production [9-11].

Taking the high manganese steel bucket tooth as the research object, the ProCAST software was used to simulate the casting process, and the location and size of the shrinkage porosity and shrinkage cavity inside the casting were predicted [12-13]. Based on the simulation results, the causes of the defects were analyzed, and the casting process was improved to enhance the casting quality, reduce the scrap rate, and increase economic benefits [14].

1. Establishment of Geometric Model

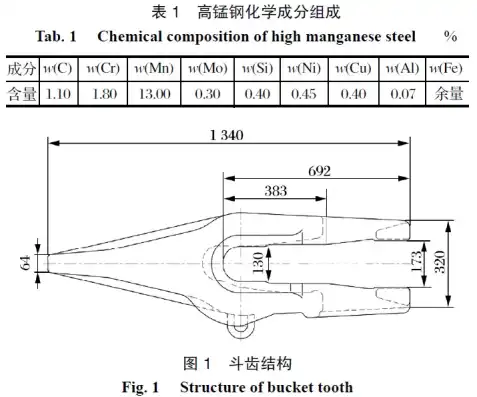

The material of the bucket tooth is high manganese steel, and its composition is listed in Table 1. The casting weight is 385 kg, and the structure is shown in Figure 1. The maximum contour size of the bucket tooth casting is 1340 mm × 425 mm × 255 mm, which belongs to a large casting.

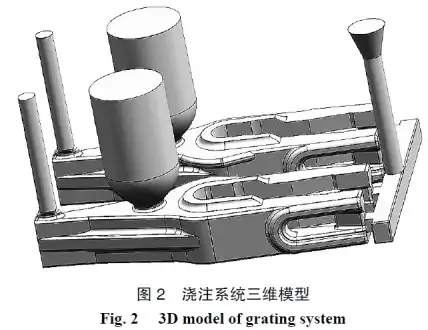

The working environment of bucket teeth is harsh, with high strength requirements. At the same time, the surface of the casting must not have surface defects such as pores, and there must be no shrinkage porosity or shrinkage cavities inside. In the actual casting production process, some casting defects are inevitable in the castings, among which shrinkage porosity and shrinkage cavities have a greater impact on the quality of the castings. As a large-sized casting, the metal liquid of bucket teeth is affected by multiple factors during the solidification process. Considering all aspects, the bottom pouring scheme is adopted, with two pieces in one box [15], as shown in Figure 2. Vent holes are set at the tip of the teeth for easy exhaust; risers are set at the thickest part of the bucket teeth center for easy feeding; the gate is set at the end of the bucket teeth, and a gate well is set at the bottom of the transverse runner for convenient slag blocking and buffering.

2. Finite Element Simulation Preprocessing

2.1 Finite Element Meshing

The 3D models of the bucket tooth and the gating system were drawn using UG software and imported into ProCAST in x-t format. The Visual-Mesh module was used to mesh the bucket tooth and the gating system. Due to the large size of the bucket tooth, the mesh size was set to 15 for a smooth simulation process. The surface mesh was corrected and repaired, and then the volume mesh was drawn based on the surface mesh, generating 224,490 surface elements and 3,405,826 volume elements.

2.2 Boundary Conditions and Operating Parameter Settings

After entering the Visual-Cast module of ProCAST, the material is selected and edited in the material library. ProCAST is used to calculate the physical performance parameters of the material, with the liquidus line at 1388.7℃ and the solidus line at 1256.8℃. The material of the mold part is selected as resin sand.

The initial process plan for the bucket tooth has a pouring temperature of 1600℃. Before pouring, the sand mold needs to be baked at high temperature, with a preheating temperature of 400℃. After baking, it is left to stand for a period of time before gravity pouring, with the gravity in the negative z-axis direction and natural air cooling. The interface heat transfer coefficient category is selected as the COINC type, and the interface heat transfer coefficient between the high manganese steel casting and the mold is set to 500W/(m2·K). The filling time is 85s, and the mold size is 1800mm×1400mm×800mm. The entire process is relatively simple, with a final step count of 50,000 steps.

3 Simulation Result Analysis

3.1 Analysis of the Temperature Field Simulation Results during the Filling Process

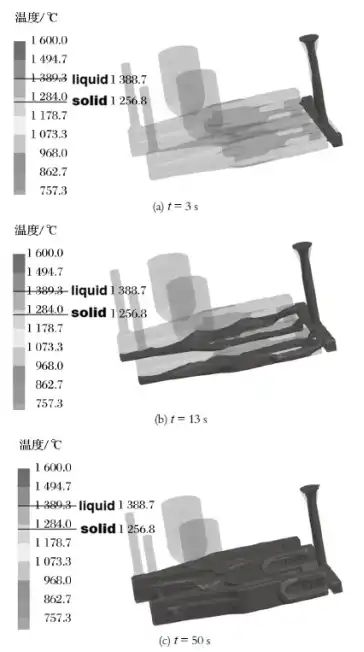

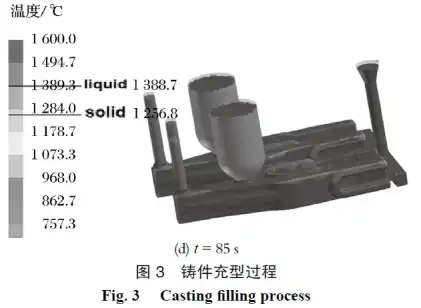

The initial casting process was simulated using ProCAST, and the filling results were analyzed. The results are shown in Figure 3. According to the Visual-Viewer module in ProCAST, during the filling process, the molten metal enters the cavity from the pouring cup, and the liquid level rises slowly. The gas in the cavity can be smoothly discharged through the gas holes at the tip of the tooth. The entire cavity is filled within 85s, and the flow of the molten metal is relatively smooth, allowing for successful filling of the cavity. During the filling process, the temperature of the molten metal is above the liquidus line, with good fluidity, and no large-scale splashing or turbulence of the molten metal occurs.

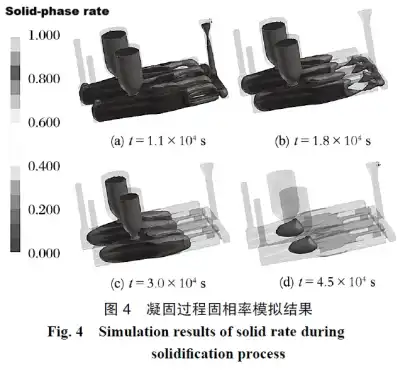

3.2 Analysis of Simulation Results of Solid Fraction during Solidification Process

The simulation results of solid fraction during the solidification process are shown in Figure 4. It can be seen from the changes in solid fraction that the fastest solidification occurs in the gas holes and the gating system. At 1.1×104 s, solidification mainly takes place in the gating system, proceeding from the sprue to the runner. At 1.7×104 s, the gating system is basically solidified, and the solidification of the casting shows a trend from left to right and from bottom to top. At 4.5×104 s, the solid fraction in the center of the bucket tooth is significantly lower than that in the surrounding area, which may lead to insufficient feeding.

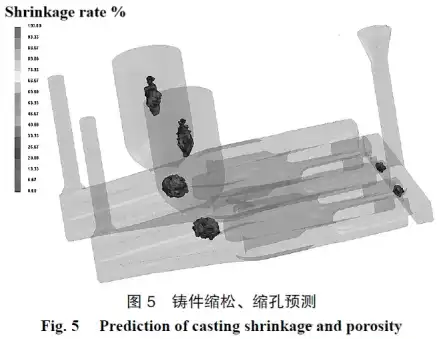

3.3 Prediction of Shrinkage Cavities and Porosity Defects in Castings

To ensure the normal use of the bucket tooth castings, it is necessary to predict the shrinkage porosity and cavity defects inside the bucket teeth. The Total Shrinkage Porosity criterion of ProCAST software is used for qualitative judgment [17]. The defects are mainly concentrated at the pouring cup, the horizontal runner, the riser, and the middle part of the bucket tooth, as shown in Figure 5. The shrinkage porosity in the middle part of the bucket tooth will seriously affect the performance of the casting and may cause the bucket tooth to break under impact loads.

4 Optimization of Process Parameters and Pouring System

According to the simulation results, it is found that the design of the above pouring process for the bucket tooth casting has not achieved the ideal expected effect on the final quality and performance of the casting. The main reasons are as follows: ① The filling speed is relatively slow [18]; ② The pouring temperature is too high [19]; ③ The preheating temperature of the mold is relatively low [20].

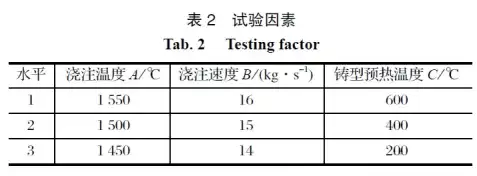

In order to reduce the casting defects of the casting, the three important process parameters of pouring temperature, pouring speed and mold preheating temperature are optimized, as listed in Table 2.

Based on Table 2, nine experimental control groups were established, and casting simulation was carried out accordingly. The optimal parameter combination was selected based on the size of the shrinkage porosity and shrinkage cavity rate at the end of the simulation, which is represented by the symbol θ. The specific simulation parameter settings and results are listed in Table 3 [21].

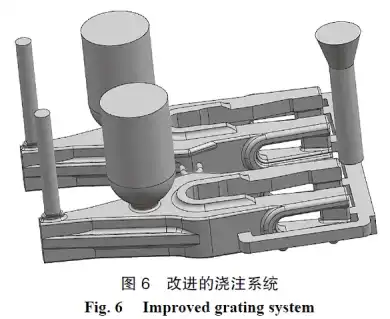

According to the simulation results in Table 3, the L7 group has the best simulation results. As the filling speed has been increased from the original 14 kg/s to 16 kg/s, in order to prevent the metal liquid from eroding the mold wall due to the accelerated filling speed, the gating system is optimized in the following ways [22]: ① Increase the diameter of the sprue to accelerate the filling speed; ② Extend two additional inner gates from both ends of the runner to improve the flow distribution in the cavity and prevent the mold wall from being eroded due to the accelerated filling; ③ Set two gate pockets at the bottom of the two additional inner gates, which can have a better slag-blocking and buffering effect during the filling process, improve the flow distribution of the inner gates, and make the filling process more stable. The improved gating system is shown in Figure 6.

5. Optimization Simulation Analysis and Production Test Verification

5.1 Analysis of Solidification Process Before and After Process Optimization

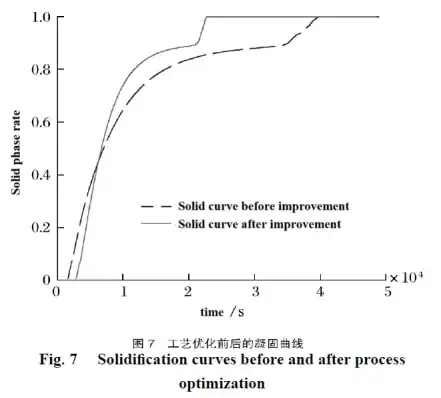

The solidification process of the areas where shrinkage porosity and shrinkage cavities occur inside the casting was analyzed. The solidification curves are shown in Figure 7. After process optimization, the solidification speed of the molten metal in this area is significantly faster than before the optimization. A faster solidification is conducive to the feeding of the molten metal, and the feeding capacity of the riser is better.

5.2 Defect Prediction after Optimization

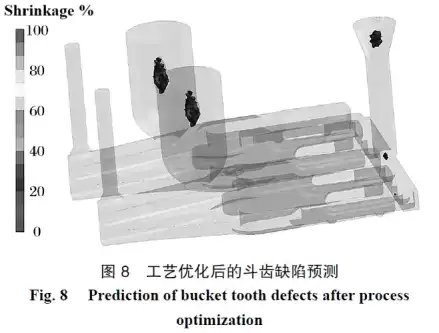

The 3D model of the optimized gating system was converted to x-t format and imported into ProCAST. Using the optimized process parameters, simulation analysis was conducted. The defect prediction of the bucket tooth after process optimization is shown in Figure 8. According to the Total Shrinkage Porosity criterion, no shrinkage porosity or shrinkage cavity defects occur inside the bucket tooth of the casting at this time. A large part of the casting defects form in the risers, and a small part form in the pouring cup and the runner, which will not affect the quality of the bucket tooth casting.

5.3 Production Verification

The actual production verification of the bucket teeth was carried out according to the parameters before and after the process optimization, as shown in Figure 9. The bucket teeth produced before the process optimization are shown in Figure 9(a), where there are significant shrinkage porosity and shrinkage cavity defects in the area directly beneath the riser. The bucket teeth produced after the process optimization are shown in Figure 9(b), with good surface quality and no shrinkage porosity or shrinkage cavity defects. Both the bucket teeth before and after the optimization are consistent with the simulation results, verifying the feasibility of using simulation to guide actual production.

5.4 Comparison of Hardness and Wear Resistance

For the same casting material of the bucket teeth, the hardness of the bucket teeth before process optimization was 205HV, and after optimization, it was 218HV. Under the impact energy of 1J, the wear amount of the bucket teeth before process optimization was 185mg, and after optimization, it was 160mg.

6 Conclusion

(1) The 3D models of the bucket teeth and the gating system were established in UG and imported into ProCAST. After meshing and setting the initial process parameters, simulation was carried out. Based on the simulation results, the three main process parameters of pouring temperature, pouring speed, and mold preheating temperature were optimized, and the optimal process parameter combination was selected: pouring temperature of 1450℃, pouring speed of 16kg/s, and mold preheating temperature of 600℃.

(2) After the casting process optimization, no shrinkage porosity or shrinkage cavities occurred inside the bucket teeth castings. The metal liquid solidified faster, the surface quality was improved, and there was also a certain improvement in hardness and wear resistance.

China Vigor has the complete production line and post treatment line for Bucket Teeth and the relevant parts of earth moving machinery, If you have any question, demand, related parts development or improve your supply chain, please feel free to contact us info@castings-forging.com