Knowledge

Methods of Metal Grain Refinement

Grain refinement of metals is one of the important means to improve the performance of metallic materials. By refining grains, the strength, hardness, plasticity and toughness of metals can be significantly enhanced, their comprehensive mechanical properties can be improved, processing performance can be optimized, and even positive impacts can be made on the corrosion resistance and thermal stability of materials. This article will introduce in detail several main methods of grain refinement of metals and their principles.

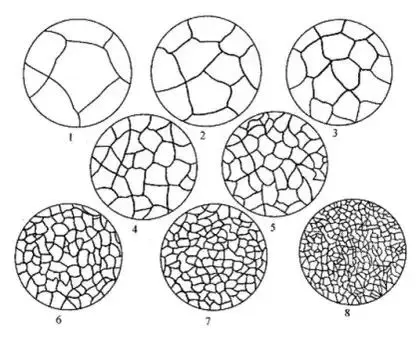

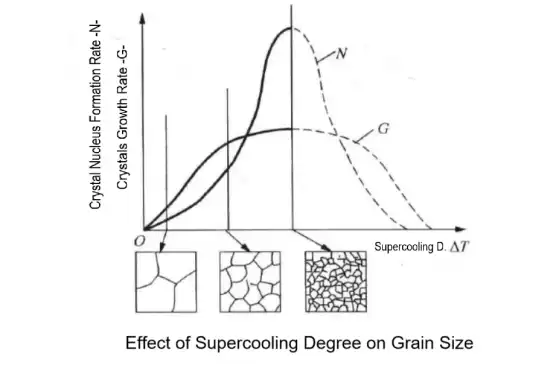

I. Increasing Undercooling

Increasing undercooling is one of the effective methods to refine metal grains. Undercooling refers to the difference between the actual crystallization temperature of the liquid metal and the theoretical crystallization temperature (i.e., the equilibrium crystallization temperature). Enhancing undercooling can promote spontaneous nucleation, increase the number of nuclei, and simultaneously inhibit grain growth, thereby obtaining fine grains.

In actual operation, the degree of supercooling can be increased through the following methods:

1. Increase cooling rate: Use molds with strong heat absorption capacity and good thermal conductivity, such as metal molds, to increase the cooling rate of liquid metals.

2. Reduce the pouring temperature: Lowering the pouring temperature of the molten metal reduces heat loss during the pouring process and increases the degree of undercooling.

3. Control the casting speed: In the production of aluminum and aluminum alloy ingots, reducing the casting speed can further increase the cooling rate of the liquid metal and enhance the degree of undercooling.

The principle of increasing undercooling lies in that the nucleation rate is proportional to the undercooling, and the grain growth rate is also related to the undercooling. However, the growth rate of the nucleation rate is greater than that of the grain growth rate. Therefore, as the undercooling increases, the nucleation rate significantly increases, while the grain growth rate is relatively slow, thereby obtaining fine grains.

II. Metamorphic Treatment

Metallurgical modification is achieved by adding certain impurities or modifiers to the liquid metal to act as foreign nuclei for non-spontaneous nucleation, thereby refining the grain structure. This process has been widely applied in industrial production, particularly in the manufacturing of cast iron and aluminum alloys.

Metamorphic treatment can be divided into two categories:

1. Nucleation modifiers: These modifiers can generate non-spontaneous nuclei and increase the nucleation rate. For instance, adding elements such as titanium and boron to aluminum alloys or elements like titanium, vanadium, and aluminum to steel can significantly increase the number of nuclei and refine the grain size.

2. Adsorption-type modifiers: These modifiers can adsorb onto the surface of crystal nuclei, hindering their growth while promoting the formation of new crystal nuclei. For instance, when sodium salts are added to aluminum alloys, they adsorb onto the surface of crystal nuclei, preventing their growth and resulting in fine grains.

The principle of modification treatment lies in that the modifier can act as a substrate for non-uniform nucleation, significantly increasing the number of nuclei and simultaneously inhibiting the growth of grains, thereby obtaining fine grains. In practical applications, factors such as the type, dosage, addition timing and melt temperature of the modifier will all affect the modification effect.

III. Vibration and Stirring

Vibration and stirring achieve the purpose of grain refinement by inputting additional energy into the molten metal, increasing energy fluctuations, and thus more effectively providing the nucleation energy required for nucleation. Common methods include mechanical vibration, ultrasonic vibration, electromagnetic stirring, etc.

1. Mechanical vibration: By vibrating the metal that is crystallizing through mechanical equipment, the melt forms three-dimensional spatial flow, promoting the fracture of alloy dendrite arms and increasing the nucleation sites. Mechanical vibration is very practical and effective in the production of some small metal products.

2. Ultrasonic vibration: When ultrasonic vibration propagates in a liquid, it causes cavitation and acoustic streaming effects, altering the flow field, pressure field and temperature field of the melt, promoting nucleation and refining grains. Ultrasonic vibration equipment can achieve uniform vibration of the metal liquid, thereby obtaining fine grains.

3. Electromagnetic stirring: By using the electromagnetic force generated through electromagnetic induction to drive the metal to flow in a regular pattern, it makes the composition and temperature of the melt more uniform and increases the number of nuclei. Electromagnetic stirring has been widely applied in the production of large metal products and can significantly enhance the grain refinement effect of metals.

The principle of vibration and stirring lies in inputting additional energy into the molten metal to increase energy fluctuations and provide the necessary nucleation energy for nucleation. At the same time, vibration and stirring can also break the growing dendrites and increase the number of nuclei, thereby achieving the purpose of grain refinement.

IV. Heat Treatment Process

Heat treatment is also one of the important methods for refining metal grains. Through heat treatment, the internal structure of metals can be altered to refine the grains. Common heat treatment processes include recrystallization annealing and normalizing treatment.

1. Recrystallization annealing: For metal materials that have undergone cold deformation, recrystallization annealing can cause the internal grains to re-nucleate and grow. By controlling parameters such as annealing temperature and time, fine and uniform grains can be obtained. Recrystallization annealing is widely used in the metal processing industry. Many metal products need to undergo this treatment after cold working to refine the grains and improve performance.

2. Normalizing treatment: Normalizing treatment involves heating the metal to an appropriate temperature and then cooling it in the air. During this process, the grains inside the metal will be adjusted, resulting in fine and uniform grains. Normalizing treatment cools down faster than annealing, so the resulting grains are relatively finer. The mechanical properties such as strength and toughness of the metal material after normalizing treatment will be improved.

The principle of heat treatment lies in altering the internal microstructure of metals to enable re-nucleation and growth, thereby achieving fine and uniform grains. In practical applications, appropriate heat treatment parameters must be selected based on the type of metal material and the performance requirements.

V. Other Methods

In addition to the above methods, there are also some other methods that can be used to refine metal grains, such as mechanical ball milling, amorphous crystallization, and rapid solidification technology.

1. Mechanical ball milling method: Through mechanical ball milling, metal powders are refined to obtain fine grains. This method is suitable for preparing nano-metal materials.

2. Amorphous crystallization method: Through the crystallization process of amorphous metals, fine and uniform grains can be obtained. This method is suitable for preparing metal materials with special properties.

3. Rapid solidification technology: By rapidly cooling the molten metal, the growth of grains is suppressed, resulting in fine and uniform grains. This method is suitable for preparing high-performance lightweight metal materials, such as magnesium alloys and aluminum alloys.

These methods each have their own characteristics and are suitable for different metal materials and application fields. In practical applications, the appropriate method needs to be selected based on specific circumstances.

Grain refinement of metals is one of the important means to improve the performance of metallic materials. By increasing the degree of undercooling, modification treatment, vibration and stirring, heat treatment processes and other methods, the grains of metals can be effectively refined, thereby enhancing their strength, hardness, plasticity and toughness. In practical applications, it is necessary to select appropriate methods based on the type of metallic materials and performance requirements, and optimize process parameters to achieve the best grain refinement effect.

If you have any question and demand of products development or improve your supply chain, please feel free to contact us at info@castings-forging.com