Knowledge

Magnesium alloy forming technology helps shape a lightweight future (magnesium alloy casting)

I. Background

In this era of pursuing efficiency and environmental protection, lightweighting has become a key direction for the development of many industries. From automobiles to aerospace, from electronic devices to medical equipment, reducing product weight not only lowers energy consumption and enhances performance but also contributes to sustainable development. In this race for lightweighting, magnesium alloys, with their unique advantages, have become the highly anticipated "star material".

Magnesium alloys, as alloys based on magnesium and combined with other elements, possess numerous advantages such as low density, high specific strength, good shock absorption, and strong electromagnetic shielding capabilities. Their density is approximately two-thirds that of aluminum alloys and one-fourth that of steel, making them highly promising in applications where weight reduction is pursued. For instance, in the automotive industry, using magnesium alloys to manufacture components can effectively reduce the vehicle's weight, thereby lowering fuel consumption and exhaust emissions. Relevant studies have shown that for every 10% reduction in vehicle weight, fuel efficiency can increase by 6% to 8%, which is of great significance for achieving energy conservation and emission reduction goals.

Magnesium alloys also play a crucial role in the aerospace field. Given that aerospace vehicles are highly sensitive to weight, every kilogram of weight reduction can bring significant benefits such as fuel savings and increased range. The low density and high specific strength of magnesium alloys make them ideal materials for manufacturing aerospace components, allowing for maximum weight reduction while ensuring structural strength.

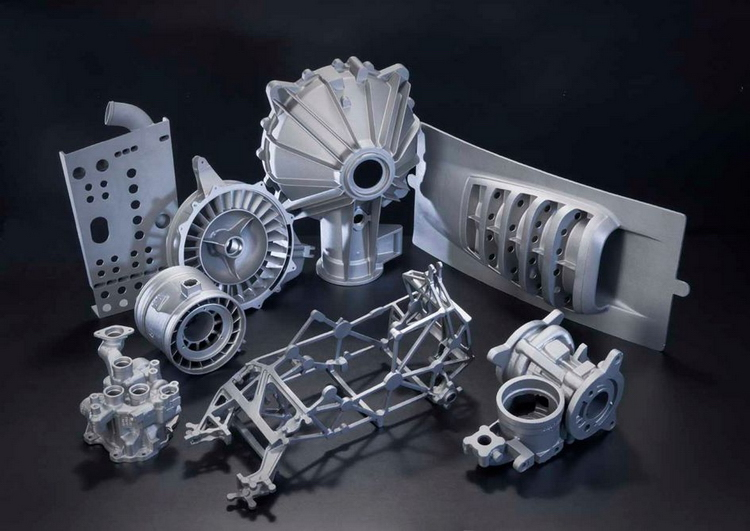

However, for magnesium alloys to fully leverage their advantages, advanced forming technologies are indispensable. These forming technologies act like magicians, capable of shaping magnesium alloy materials into various forms and structures to meet the demands of different industries. Now, let's embark on a journey into the fascinating world of magnesium alloy forming technologies and explore the mysteries of casting magnesium alloys, wrought magnesium alloys, and semi-solid injection molding technologies.

II. Introduction to Magnesium Alloy Forming Technologies

Based on the forming processes, magnesium alloys are mainly classified into casting magnesium alloys and wrought magnesium alloys, with their primary forming methods as follows:

Casting magnesium alloys mainly obtain magnesium alloy products through casting, including sand casting, die casting, and pressure casting (die-casting). Among them, die-casting is the most mature and widely used technology. Currently, over 90% of magnesium alloy products are formed by die-casting. The semi-solid injection molding of magnesium alloys on the rise also uses casting magnesium alloys as production raw materials. The results show that magnesium alloy products formed by semi-solid injection molding often have higher strength. See the evaluation video below.

Deformed magnesium alloys are produced through deformation into various-sized plates, bars, tubes, profiles and forgings. High-strength and high-ductility components can be obtained through the control of material microstructure and heat treatment processes.

III. Casting Magnesium Alloy Forming Technology: Innovation of Traditional Processes

Casting is one of the most commonly used methods for forming magnesium alloys. It involves pouring liquid magnesium alloy into a mold cavity and allowing it to cool and solidify to obtain parts of the desired shape. This method has the advantage of being able to manufacture complex-shaped parts and holds an important position in the field of magnesium alloy forming. Currently, over 70% of magnesium alloy parts worldwide are produced through casting processes. The main casting magnesium alloy forming technologies include the following:

1. Sand Casting: Customized Solutions for Large and Complex Parts

Sand casting is a relatively traditional casting method that uses materials such as quartz sand and clay as molding materials. The core and mold box are made by hand or machine to form the casting cavity. The advantage of this method is that the cooling rate of the sand mold is relatively slow (approximately 0.5 - 2°C/s), which is beneficial for the feeding of the casting and can effectively prevent defects such as shrinkage cavities and cracks in large parts. Therefore, sand casting is widely used in the aerospace industry to manufacture large structural components, such as helicopter casings and satellite brackets.

However, sand casting also has some limitations. Its production cycle is relatively long, with a single-piece production typically taking 3-5 days, and the dimensional accuracy is relatively low, with a tolerance range of ±1-3mm. This makes sand casting more suitable for the production of small batches of high-value parts.

2. Metal Mold Casting: An Efficient Choice for Mass Production of Medium and Small Parts

Metal mold casting uses permanent molds made of steel (i.e., metal molds) to directly pour liquid magnesium alloy into the mold by gravity. Compared with sand casting, the cooling rate of the metal mold is faster (generally 5 - 15°C/s), which can refine the grain structure and increase the strength of the casting by 15% - 20% compared to parts made by sand casting. Additionally, metal molds can be reused, with a lifespan of over 100,000 times, significantly improving production efficiency. Compared to sand casting, the production efficiency can be increased by 5 - 10 times.

Based on these advantages, die casting is highly suitable for mass production of medium and small parts in the automotive and 3C fields, such as automotive steering knuckles and laptop casings. However, die casting is not without its drawbacks. Due to the excellent thermal conductivity of the metal die, it can cause the magnesium alloy melt to solidify rapidly, which poses challenges in filling thin-walled (less than 3mm) and complex cavities.

3. Pressure Casting: The Mainstream Process for High-Efficiency Mass Production

Pressure casting involves injecting molten magnesium alloy into a mold cavity under high pressure (typically 5 - 150 MPa) and high speed (ranging from 5 - 50 m/s), allowing it to solidify instantly. Conventional pressure casting boasts extremely high production efficiency, with a single mold cycle as short as tens of seconds and a production rate of 30 - 180 pieces per hour. It is highly suitable for large-scale mass production of standardized parts, such as mobile phone frames and car door handles.

However, the internal structure of common die-cast parts often contains a large number of micro-pores, with a porosity generally ranging from 2% to 5%. This makes it impossible for the parts to undergo heat treatment for strengthening and they cannot withstand high-temperature environments (above 120℃). To address this issue, two improved technologies, oxygen-charged die-casting and vacuum die-casting, have emerged in the industry.

In oxygen injection die casting, oxygen is injected into the mold cavity before filling. The magnesium alloy melt reacts with oxygen to form MgO particles, which can fill the pores, allowing the casting to undergo heat treatment and improving its corrosion resistance by 300%.

Vacuum die casting is a process that eliminates gases in the mold cavity by reducing the vacuum level to below 50 mbar, reducing the porosity of the castings to less than 0.5% and increasing their strength by 25%. It can be used to manufacture load-bearing components such as motor housings for automobiles.

Meanwhile, we also notice that when magnesium alloys are produced by traditional die-casting methods, high-temperature furnaces are required, which not only consume a lot of energy but also pose significant safety risks: the high reactivity of magnesium makes it extremely prone to catching fire and burning when exposed to air at high temperatures.

Vigor has more than 20 years experience and the professional team in casting, die-forging and the post treatment processes. If you have any question or products need to do, please feel free to contact us at info@castings-forging.com