Knowledge

Introduction to Trace Elements in Ductile Iron ( Part Six)

Trace elements in ductile iron

During the manufacturing process of ductile iron, there are a series of trace elements that interfere with the spheroidization process. Although the mass fraction of these elements in ductile iron is only a few parts per ten thousand or a few parts per hundred thousand, they can significantly affect the spheroidization effect. This interference is closely related to the magnesium content in the melt and the cooling rate, and the effects of various interfering elements are superimposed.

Common interfering elements include Sb, Sn, Bi, Te, Pb, Ti, Se and As, etc. These elements can be classified according to their consumption characteristics of magnesium: Te and Se belong to magnesium-consuming type, which are prone to combine with magnesium and promote the formation of vermicular graphite, undercooled graphite and flake graphite; Sb, Sn, As and Ti belong to grain boundary segregation type, which tend to form distorted graphite at the grain boundaries; while Pb and Bi belong to the mixed type, forming distorted graphite at low content and promoting the formation of undercooled graphite and flake graphite at high content.

To suppress the anti-spheroidizing effect of these trace interfering elements or to broaden their allowable range, rare earth elements can be added to ductile iron. The addition amount of rare earth elements should be adjusted according to the purity of the molten iron, and it is usually appropriate for the residual cerium mass fraction to reach 0.03%.

It is particularly worth mentioning the lead element. When the iron liquid contains lead and the mass fraction is between 0.01% and 0.05%, in order to achieve a spheroidization rate of over 85%, the mass fraction of residual magnesium must exceed 0.6%, and the mass fraction of residual cerium also needs to reach above 0.05%.

Next, we will delve into the outstanding one among these trace elements.

Tellurium

Basic Information

Element Name: Tellurium

Element Symbol: Te

Atomic Number: Relative Atomic Mass:

Physical Properties

Appearance and Form: Tellurium exists in two allotropes, crystalline and amorphous. Crystalline tellurium has a silvery-white metallic luster, while amorphous tellurium is brown.

Density and Hardness: The density of crystalline tellurium is approximately 25 g/cm³, and its hardness is 5 (Mohs scale). In contrast, the density of amorphous tellurium is slightly lower, at 0.0 g/cm³.

Melting and Boiling Points: The melting point of tellurium is about 452°C, and its boiling point reaches 1390°C.

Conductivity and Thermal Conductivity: Tellurium has good thermal and electrical conductivity and is an excellent semiconductor material.

Chemical Properties

Stability: At room temperature, elemental tellurium is relatively stable in air, but it reacts with oxygen when heated, producing a blue flame and forming tellurium dioxide.

Reactivity: Tellurium can react with halogens but does not directly react with sulfur and selenium. It is soluble in sulfuric acid, nitric acid, potassium hydroxide, and potassium cyanide solutions, but is insoluble in cold and hot water as well as carbon disulfide.

Valence: The main valences of tellurium include +4 and +6. Its chemical properties are similar to those of sulfur and selenium, but tellurium is more metallic in nature.

Application fields

Metallurgical industry: Tellurium and its compounds are often used as alloy additives to improve the mechanical processing performance of steel and cast iron. At the same time, they can also enhance the durability, strength and corrosion resistance of metals such as lead and tin.

Chemical industry: Tellurium has multiple applications in the chemical industry, such as a catalyst for petroleum cracking and a vulcanizing agent for rubber.

Electronic industry: Tellurium plays an important role in the electronic industry. As a key component of semiconductor materials, it is widely used in solar cells, optoelectronic devices and other fields.

Other fields: In addition, tellurium can also be used in glass colorants, ceramic manufacturing, plastic processing, as well as in dyeing, painting and skin care products industries.

The role of tellurium in ductile iron

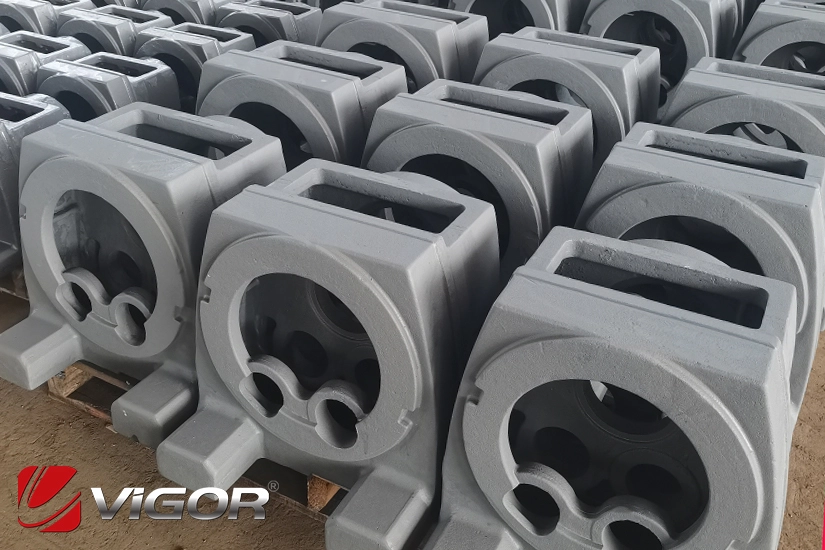

During the production of ductile iron, tellurium plays a role similar to that of sulfur. It mainly consumes magnesium, thereby reducing the magnesium content required for spheroidization and causing graphite distortion. Especially in the production of ductile iron with thick and large sections, such as the manufacturing of rolls, the addition of trace amounts of tellurium helps to improve and prevent the occurrence of graphite distortion.

If you have any question, demand, new parts of ductile iron castings need to be developed or improve your supply chain, please feel free to contact us info@castings-forging.com